A new energy vehicle drive motor enameled wire paint remover remover machine

A new energy vehicle and drive motor technology, applied in the direction of circuits, electrical components, circuit/collector components, etc., can solve the problems of stabbing hands, low removal efficiency, and low safety, and achieve faster drying speed and removal efficiency High and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

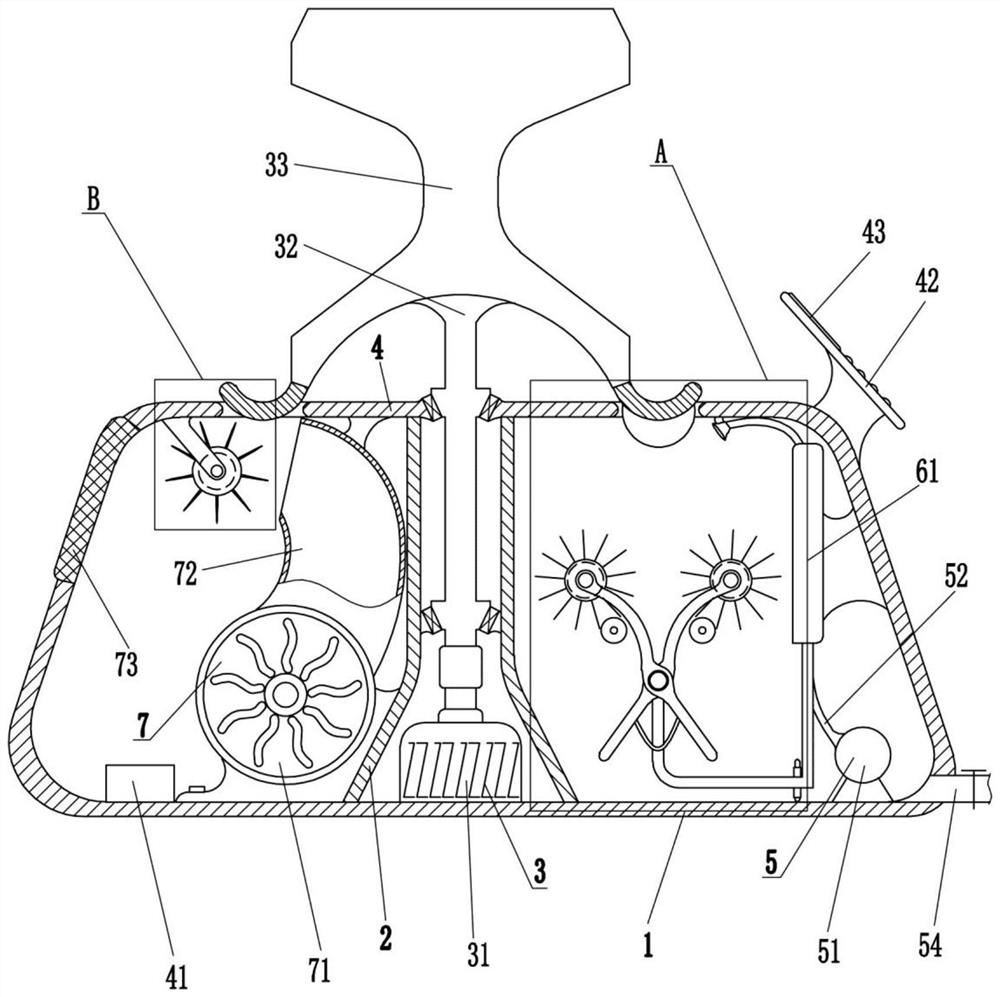

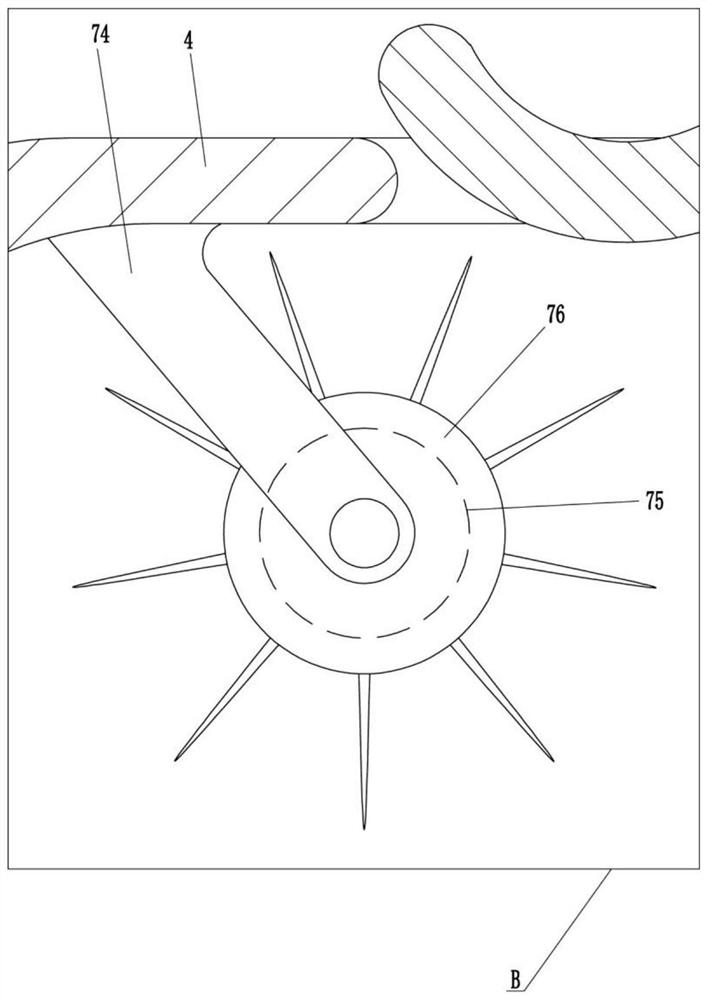

[0025] as attached figure 1 with Figure 5 As shown, a new energy vehicle drive motor enameled wire paint remover remover includes a box 1, a partition 2, a rotating mechanism 3, a horizontal plate 4 and a flushing mechanism 5, and the middle part of the box 1 is connected with two A partition 2, a rotating mechanism 3 is provided between the two partitions 2, the rotating mechanism 3 is used to drive the enameled wire to rotate, the top of the two partitions 2 is connected with a horizontal plate 4, and the right side of the inner bottom of the box body 1 is equipped with a flushing mechanism 5. The flushing mechanism 5 is used to flush the enameled wire.

[0026] as attached figure 1 , Image 6 with Figure 7 Shown, also comprise control module, LCD display screen 43, setting key, plus one key, minus one key and confirmation key, LCD display screen 43, setting key, plus one key, minus one key and confirmation key are all connected with control module through electrical ...

Embodiment approach 2

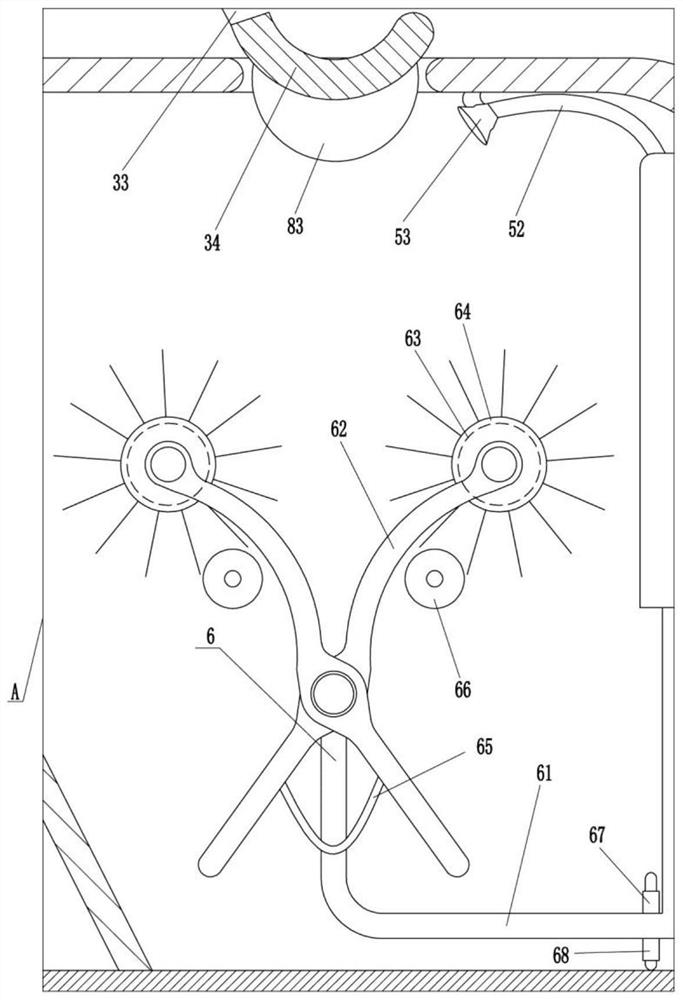

[0033] On the basis of Embodiment 1, as attached figure 1 with figure 2 As shown, a cleaning mechanism 6 is also included, and the cleaning mechanism 6 includes an electric push rod 61, a hinged frame 62, a first driving motor 63, a first roller brush 64, a shrapnel 65, a roller 66, a first travel switch 67 and a second Stroke switch 68, an electric push rod 61 is installed on the right side of the box body 1, and the box body 1 is connected with the electric push rod 61 through a bolt connection mode. The electric push rod 61 is rotatably connected with two hinged frames 62. The first drive motor 63 is installed on the top of the frame 62, and the first roller brush 64 is rotatably connected to the top of the two hinged frames 62, and the rear end of the first roller brush 64 is connected with the output shaft of the first drive motor 63. A shrapnel 65 is connected between the frames 62, and two rollers 66 are mounted on the rear right side of the box body 1 in a rotating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com