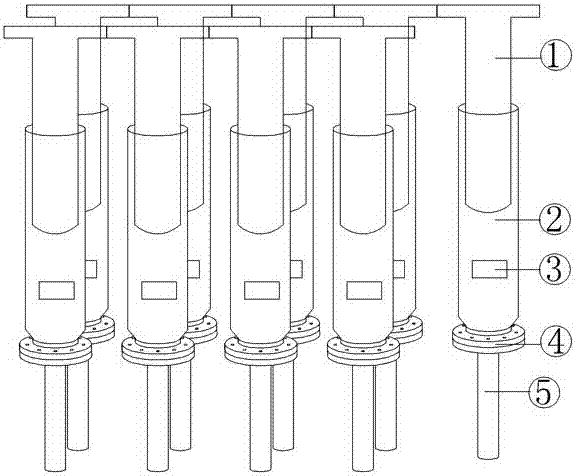

Nine-column rod maker

A raw material barrel and circular technology, applied in the field of nine-column rod making device, can solve the problems of uneven heating and burning of raw materials, waste of raw materials in production, insufficient dry distillation and evaporation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] In the figure, nine pressurized circular bodies ① are inserted into nine raw material barrels ② at the same time, and the raw materials that enter the nine raw material barrels ② from the nine feed ports ③ are simultaneously pressurized and encrypted. There is a feeding port ③ under each raw material barrel ②. The lower ends of the nine raw material barrels ② are connected with flanges ④ of the same size with an outer diameter of 0.18 meters and a thickness of 0.035 meters. The planes of the nine flanges ④ are connected vertically in the middle with a length of 0.45 meters and an outer diameter of 0.12 meters. The size of the circular die barrel ⑤. In the middle of nine flange plates 4. and nine circular mold barrel bodies 5. there are holes of the same size. Under the action of external high-strength pressure, the nine pressured circular bodies ① pressurize and densify the production raw materials in the nine raw material barrels ② at the same time, so that the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com