Locking mechanism of automobile seat slide rail

A technology of car seat slide rail and locking mechanism, which is applied to vehicle seats, movable seats, special positions of vehicles, etc., can solve the problem that deformation cannot be guaranteed, the impact of vehicle strength cannot be satisfied, and locking stability cannot be guaranteed. And reliability and other issues, to achieve the effect of no self-locking, small footprint, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The applicant will describe in detail in the form of the following examples, but the description of the examples is not a limitation to the technical solution of the present invention, and any equivalent transformation made according to the concept of the present invention is only a formal rather than a substantive equivalent transformation All should be regarded as the scope of the technical solution of the present invention.

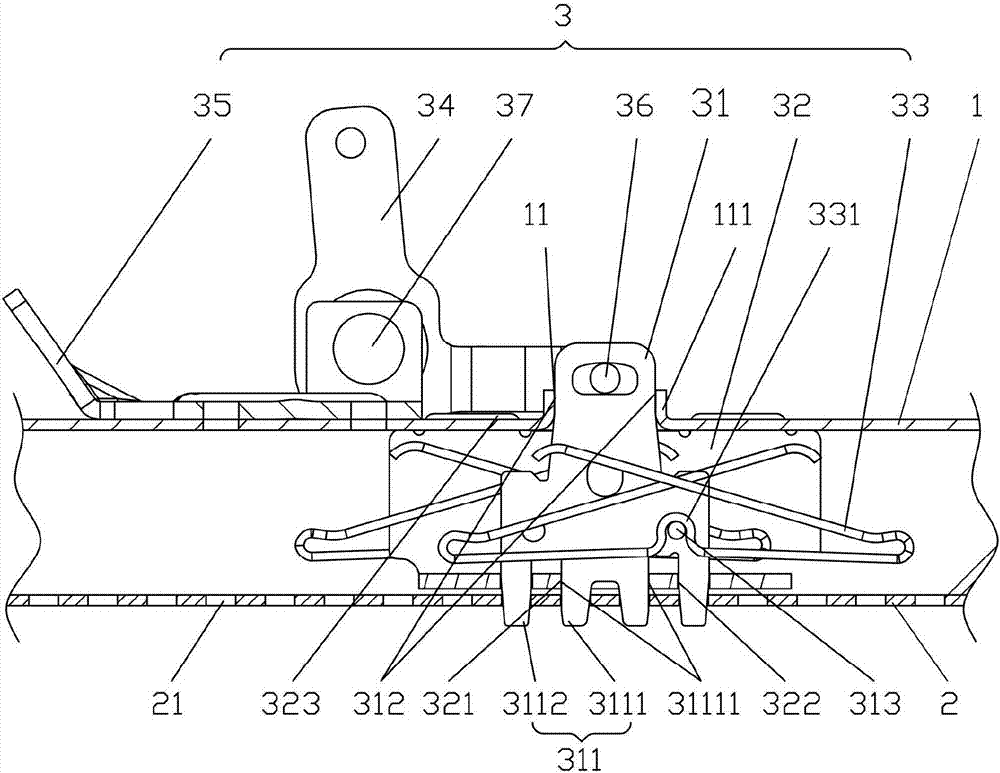

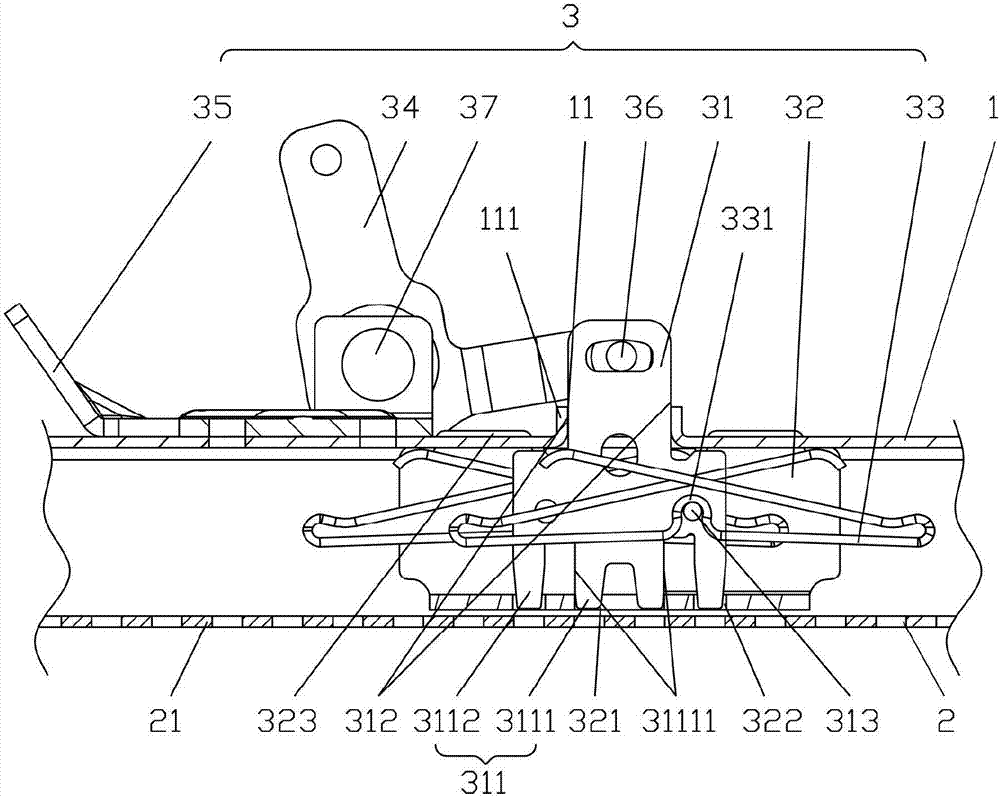

[0022] In the following descriptions, all concepts related to directionality or orientation of up, down, left, right, front and back are based on figure 1 The position shown is a reference, so it cannot be understood as a special limitation on the technical solution provided by the present invention.

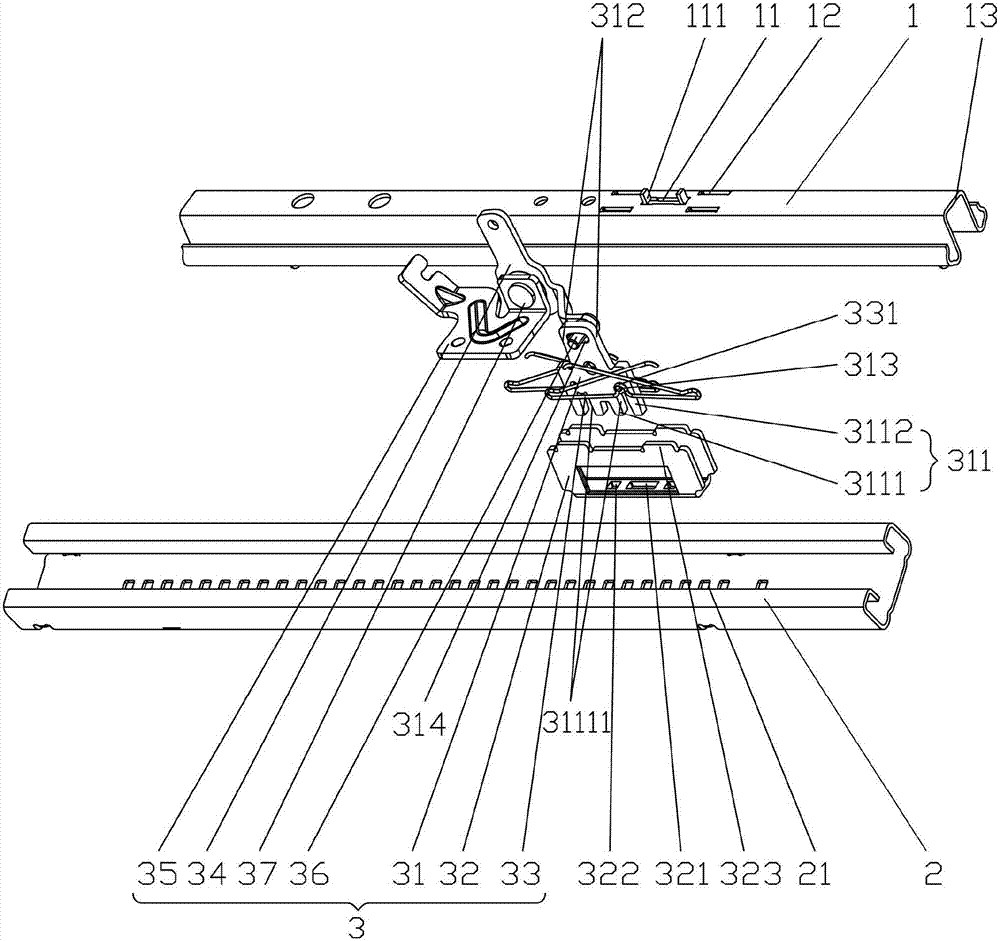

[0023] Please refer to figure 1 and combine figure 2 , image 3, the present invention is a kind of locking mechanism of car seat slide rail, described car seat slide rail comprises moving guide rail 1, fixed guide rail 2 and is located at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com