Separative supply device of compression coil spring

A technology for compressing coil springs and supplying devices, applied in the directions of transportation, packaging, conveyors, etc., can solve the problems of inability to be directly practical in industrial sites, low efficiency of kinked springs, and lack of general activation, so as to improve separation efficiency and discharge efficiency, The effect of reducing manufacturing cost and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

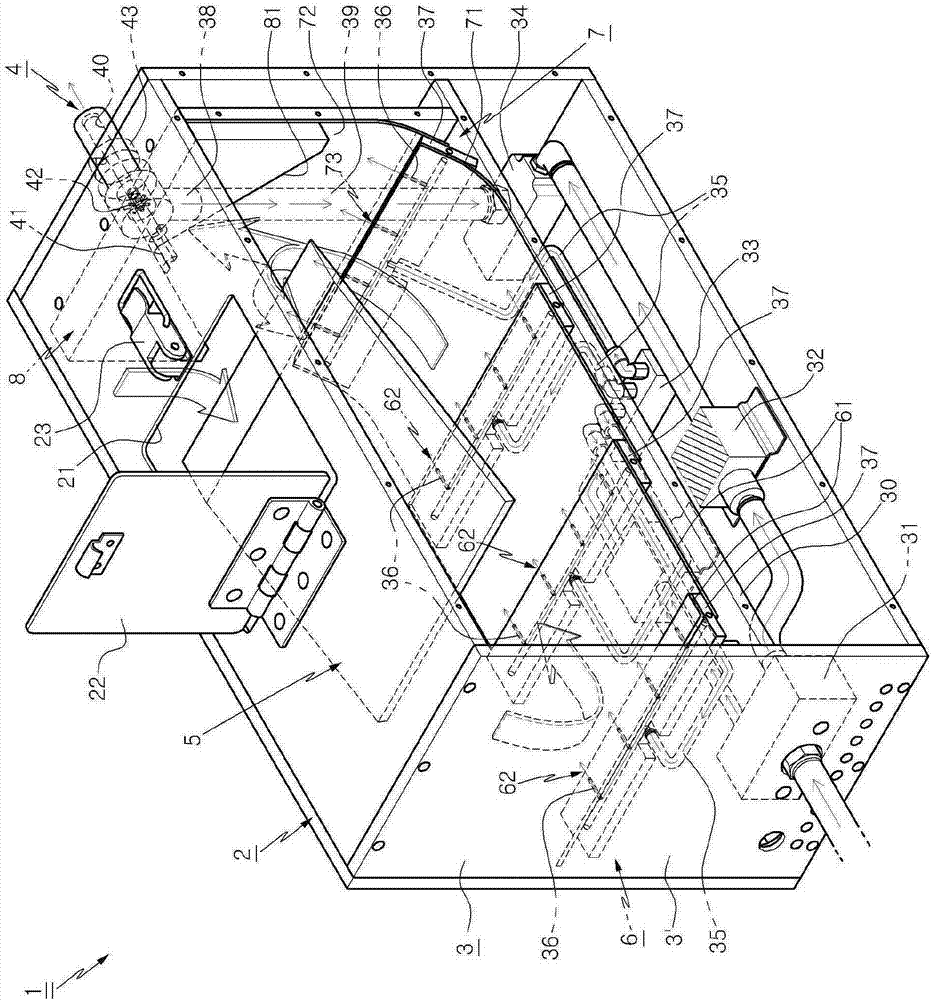

[0024] The present invention relates to a separate supply device for compressed coil springs. After forming a large number of rod-shaped rods into helical compressed coil springs in a former, they are twisted with each other during storage and transportation. It can be supplied individually by using a twisted compression coil spring, and it can be supplied separately. Figure 1 A more specific description of this is as follows.

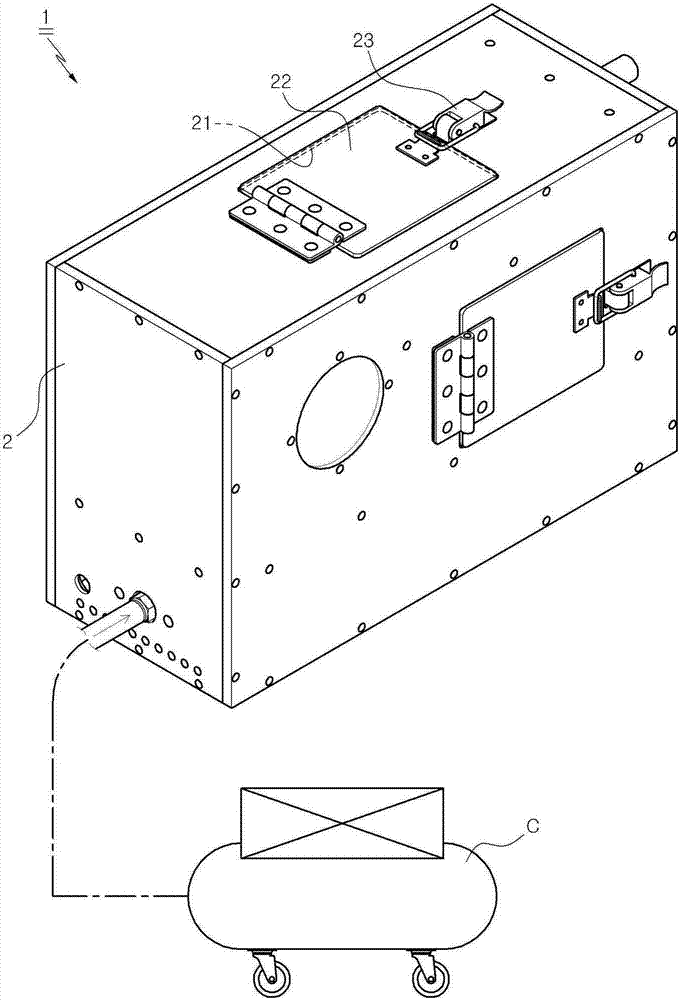

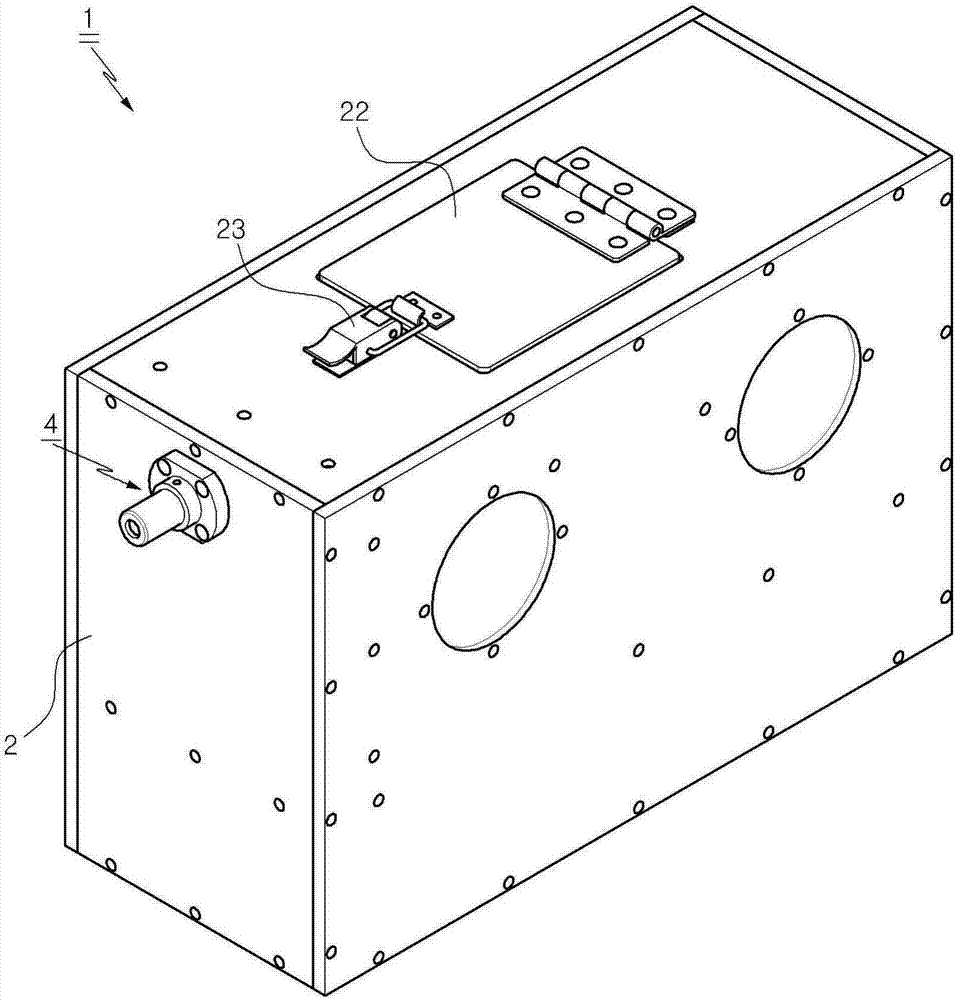

[0025] As shown rear and right side profile figure 1 and showing the front and left sides figure 2 The above-mentioned separation supply device 1 of the above-mentioned compression coil spring S of the present invention is in the main body part 2 that is formed by hexahedron, after above-mentioned molding as above, with the mode that can throw in the compression coil spring S of kinking, insert opening 21 through inwardly and outwardly to form, input The mouth 21 is opened and closed by the input door 22 provided with the locking unit 23 such as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com