Novel diaphragm capable of reducing tightening torque of middle flange fastener

A technology of tightening torque and fasteners, applied in the direction of diaphragm, diaphragm valve, engine components, etc., can solve the problem of high structural design cost and material cost, excessive tightening torque of flange fasteners, and tightening torque of flange fasteners. Large and other problems, to achieve the effect of improving production efficiency and yield, good sealing performance, and reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

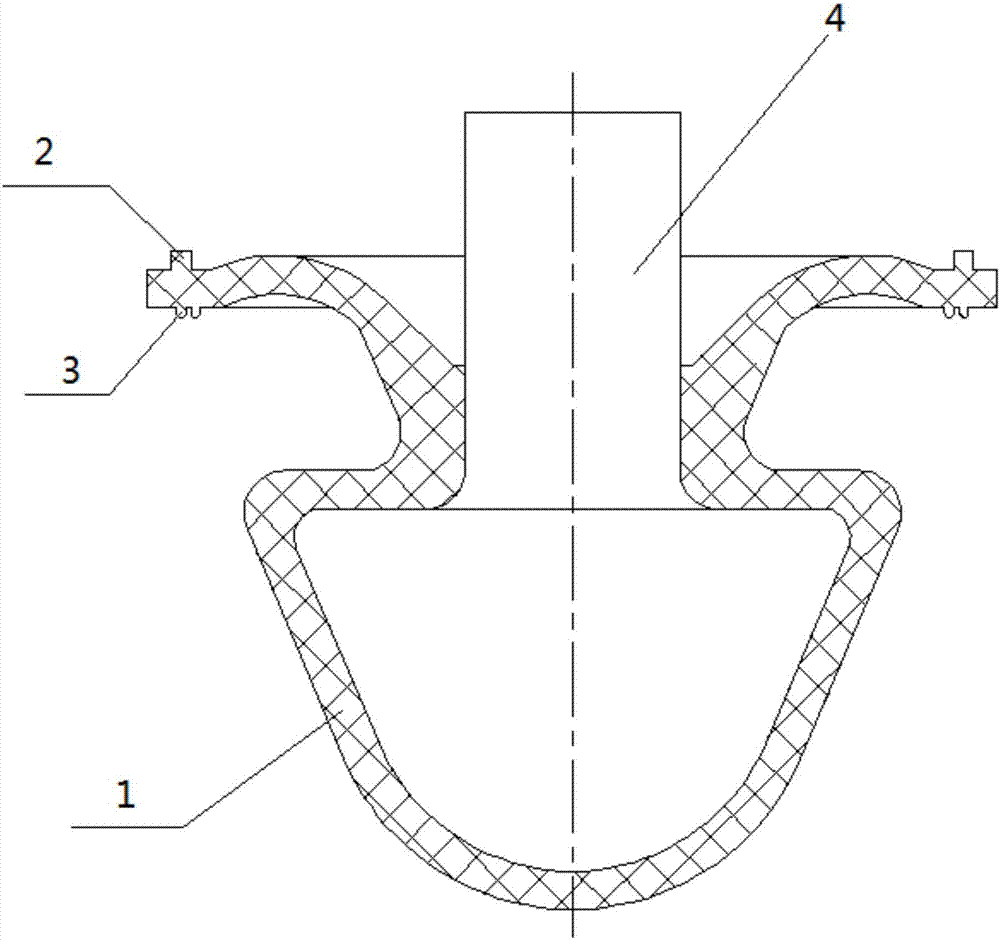

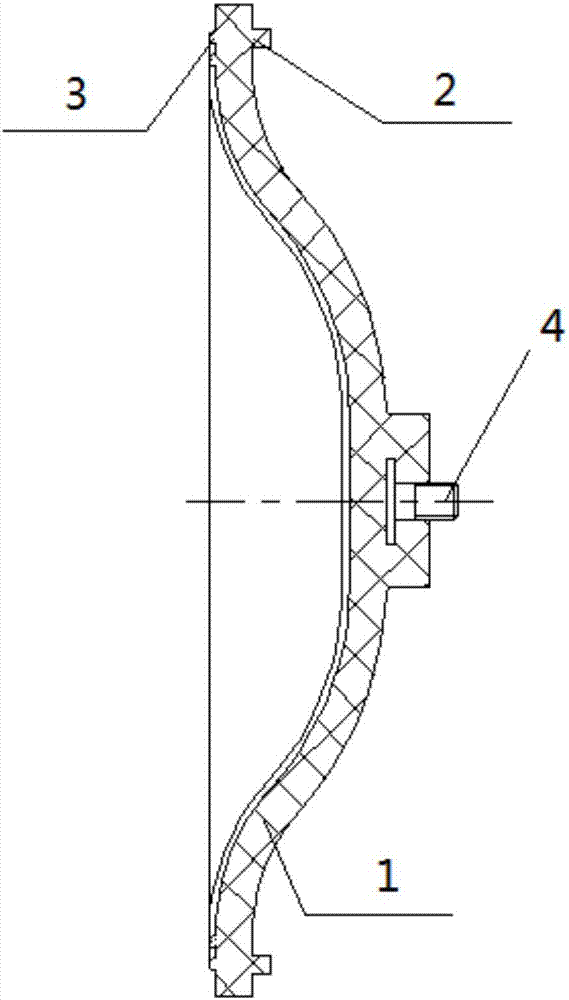

[0025] A new type of diaphragm that can reduce the tightening torque of middle flange fasteners, its structure is as follows figure 1 or figure 2 As shown, including the diaphragm body 1, the diaphragm flange surface located at the edge of the diaphragm body 1 is in sealing connection with the middle flange assembly. The middle part of the diaphragm body 1 is provided with a connecting cavity for connecting the valve stem of the diaphragm valve. A reinforcing rib 2 is provided on one side of the blue surface, and the reinforcing rib 2 is arranged around the edge of the diaphragm body 1 , and its shape is consistent with the outline of the outer edge of the diaphragm body 1 . The other side of the diaphragm flange surface of the diaphragm body 1 is also provided with two rings of sealing ribs 3 surrounding the edge of the diaphragm body 1 . The sealing rib 3 is provided with two turns. The inside of the connecting cavity is matched with the end of the valve stem of the diaph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com