Dry garbage gasification furnace

A gasification furnace and drying technology, applied in the field of garbage disposal equipment, to achieve the effect of preventing the spread of stench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

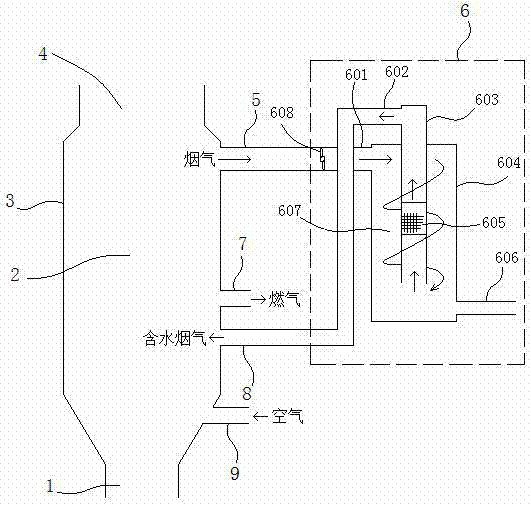

[0013] See figure 1 , the dry garbage gasification furnace provided by the present invention comprises a furnace body 3, the upper part of the furnace body 3 is provided with a feeding port 4 and a flue gas outlet 5, and the lower part is provided with an ash outlet 1 and an air inlet 9; the middle of the furnace body 3 The pyrolysis gasification reaction chamber 2 is provided with a gas outlet 7 and a flue gas recovery inlet 8, and a flue gas treatment and recovery device 6 is provided between the flue gas outlet 5 and the flue gas recovery inlet 8; the flue gas treatment and recovery device 6 includes an external The cylinder 604, the inner cylinder 603 arranged in the outer cylinder 604 along the axis, the airflow passage 607 between the inner cylinder 603 and the outer cylinder 604, the outer cylinder 604 is provided with a flue gas inlet 601 through the pipe and the fan 608 and the flue gas of the furnace body 3 The outlet 5 is connected, and the bottom of the outer cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com