Combustion device for treating waste gas of waste incineration

A combustion device and waste incineration technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of serious atmospheric pollution, unsatisfactory incineration results of incinerators, incomplete gas combustion, etc., and achieve pollution-free emissions , prevent the spread of stench and reduce the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

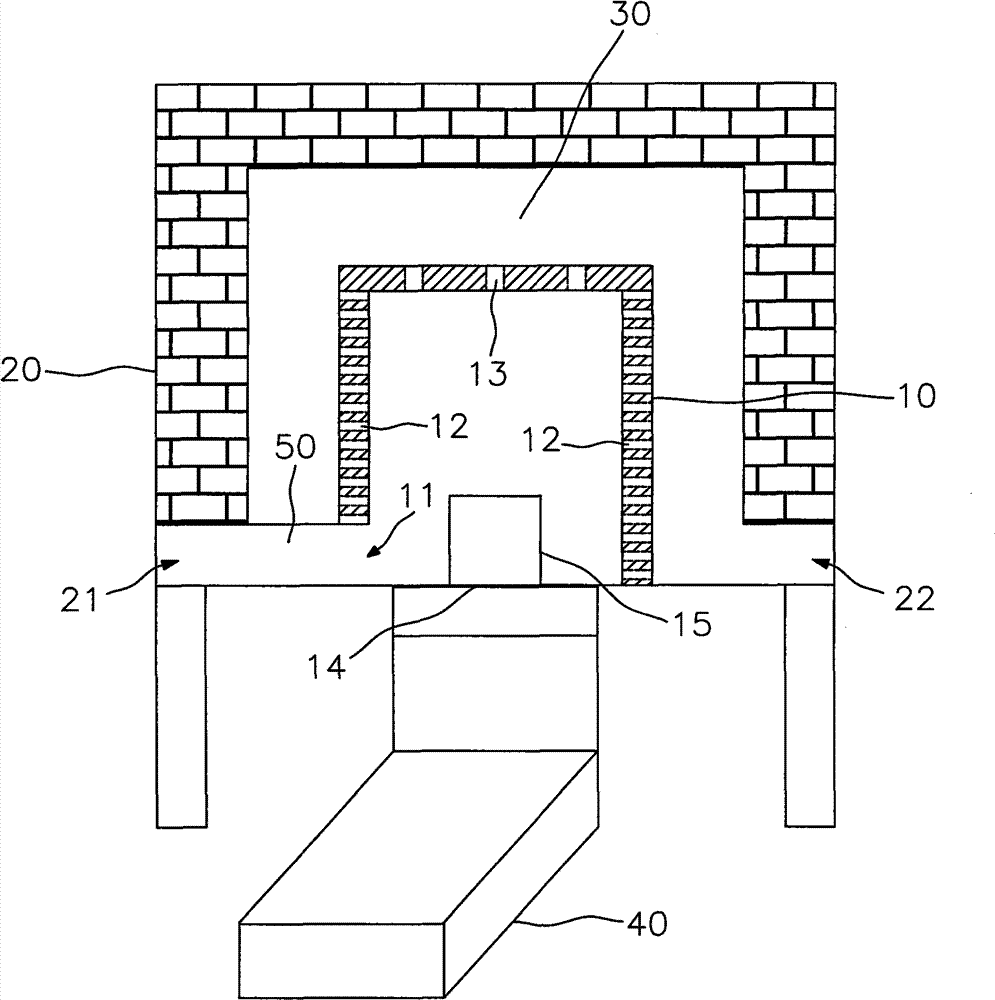

[0008] Such as figure 1 As shown, a combustion device for treating waste gas from waste incineration, the combustion device includes a hollow first shell 10, and the first shell 10 is provided with a first air inlet 11 for the waste gas from waste incineration to enter. and the fuel inlet 13 that injects fuel to burn and completely decomposes dioxin and organic pollutants in the waste incineration waste gas entering the first casing 10, and the first casing 10 is also provided with a fuel inlet 13 for discharging the treated waste incineration waste gas. The first exhaust port 12, the lower side of the first housing 10 is provided with an ash discharge port 14, and the ash discharge port 14 is provided with a gate valve.

[0009] During actual processing, waste incineration waste gas enters the first housing 10 from the first air inlet 11 , and is discharged through the first exhaust port 12 after being pyrolyzed inside the first housing 10 .

[0010] The time required for di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com