Garbage gasification furnace

A gasification furnace and garbage technology, applied in the field of garbage incineration, can solve the problems of incomplete gas combustion, air pollution, high water content of garbage, etc., and achieve the effect of preventing the spread of odor and ensuring sufficient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

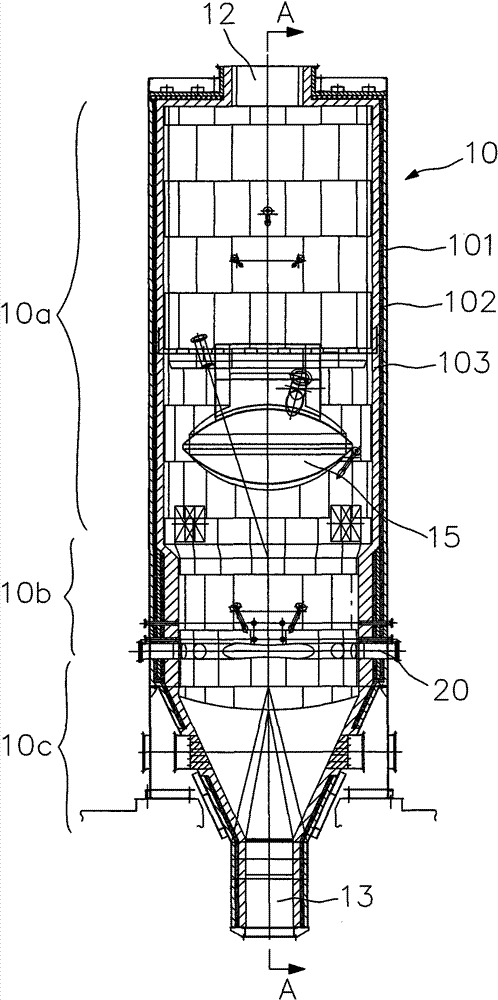

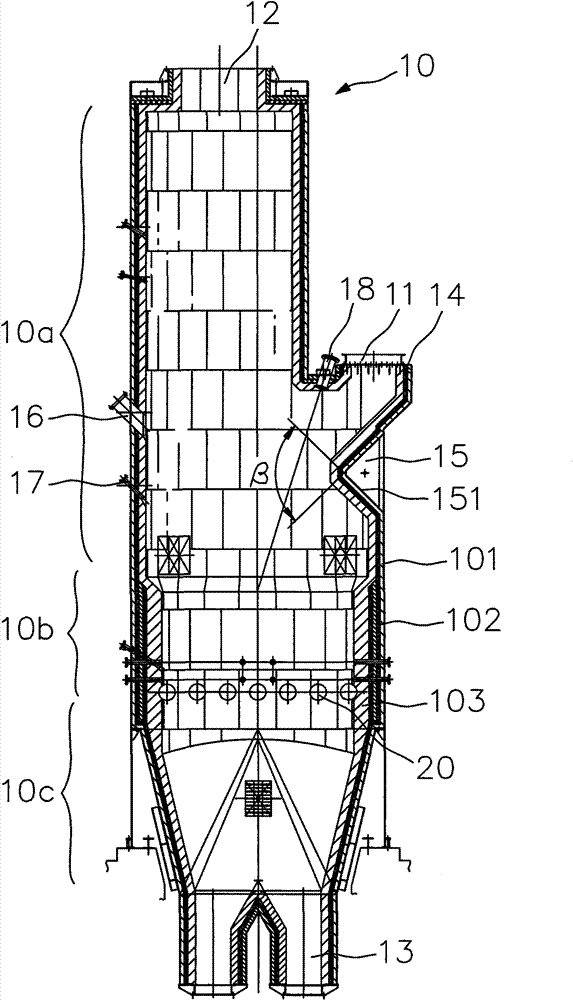

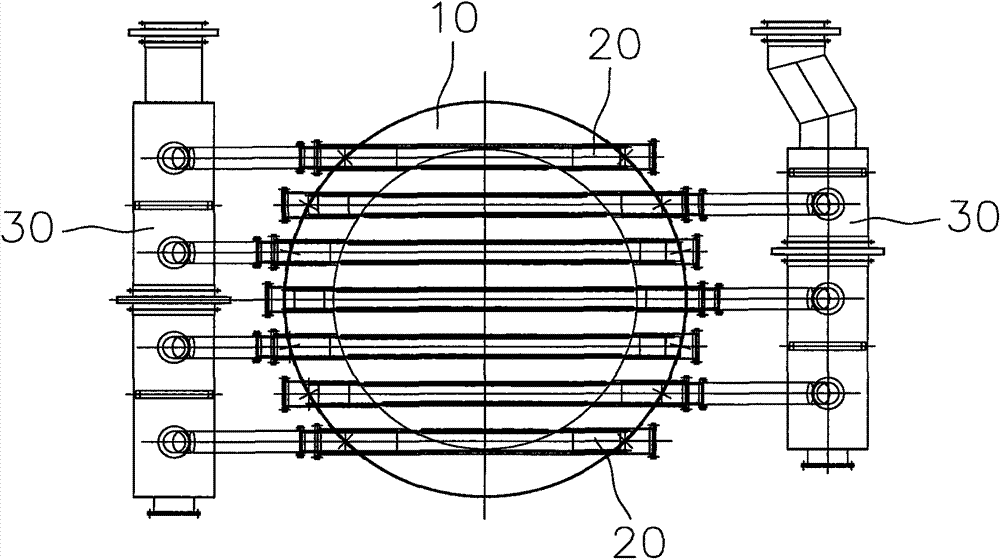

[0011] Such as figure 1 As shown, a garbage gasifier, the garbage gasifier includes a cylindrical shell 10, the upper side of the shell 10 is divided into a material input port 11 and a flue gas outlet 12, the lower side of the shell 10 is provided with a discharge The slag port 13, the middle and lower part of the shell 10 is filled with fluidized sand, the air diffuser pipe 20 penetrates the inner side of the shell 10 from the outside of the shell 10 and is buried in the fluidized sand, and the air diffuser pipe 20 is located at the air intake outside the shell The end is connected with the hot blast stove, and the diffuser pipe 20 is provided with diffuser holes on the tube body inside the shell, and the hot blast stove cooperates with the diffuser pipe 20 to make the fluidized sand be in a static deposition state or a boiling fluidized state.

[0012] When starting to work, the hot blast stove blows hot air at 500°C into the housing 10 through the air diffuser 20, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com