Liftable chimney used for garbage incinerator

A technology for waste incinerators and chimneys, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of the old chimneys with single function, large use space, and chimneys occupying a large vertical height, so as to reduce pollution and prolong service life. , to achieve the effect of pollution-free emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

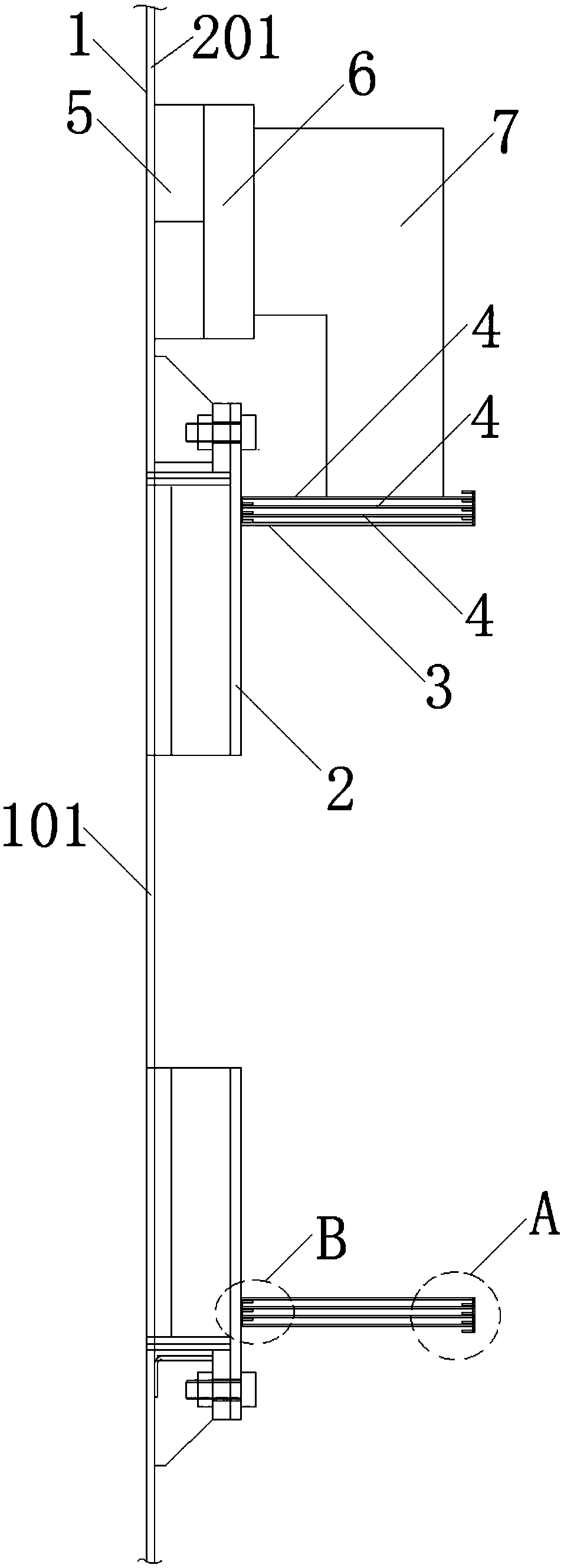

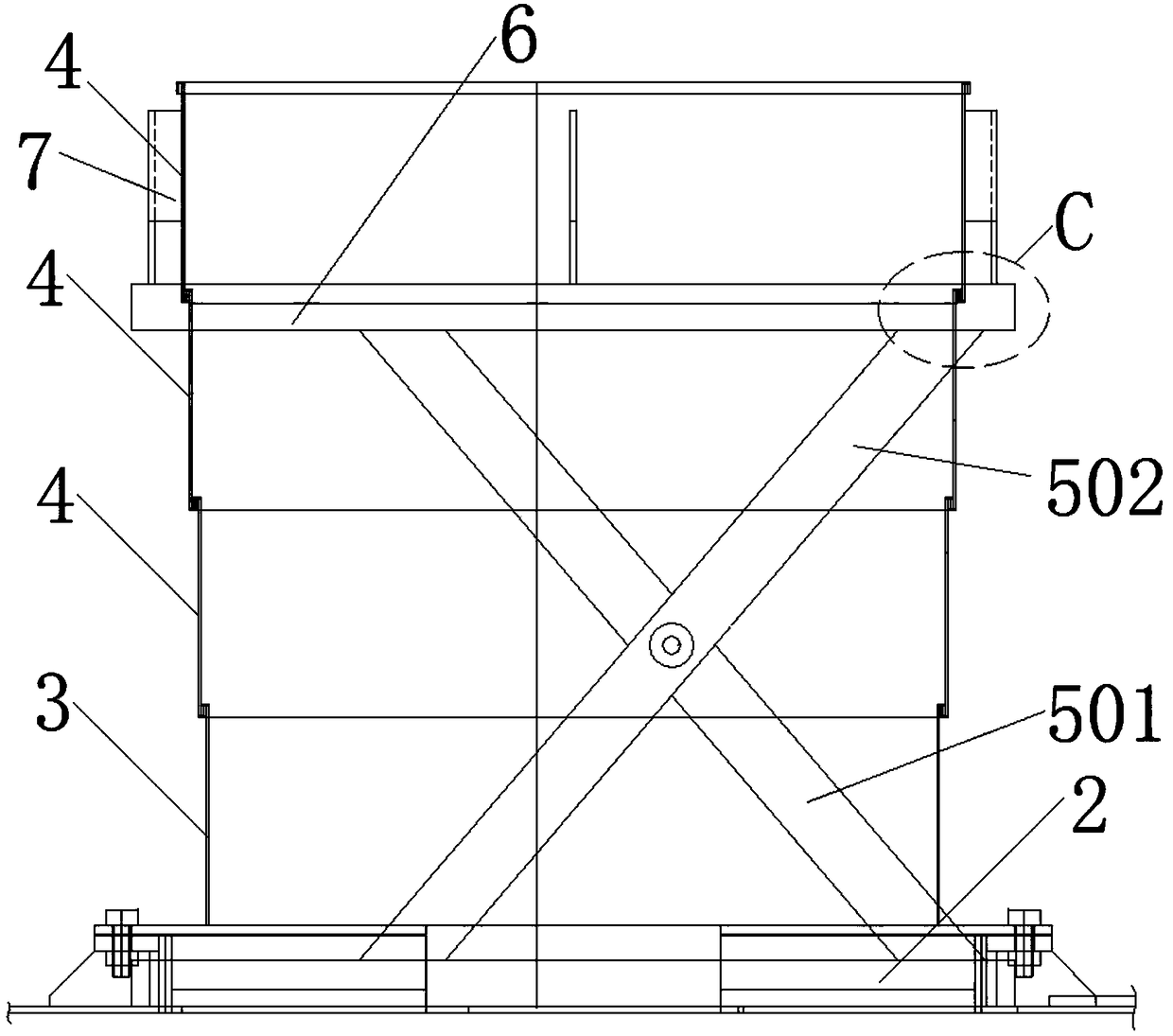

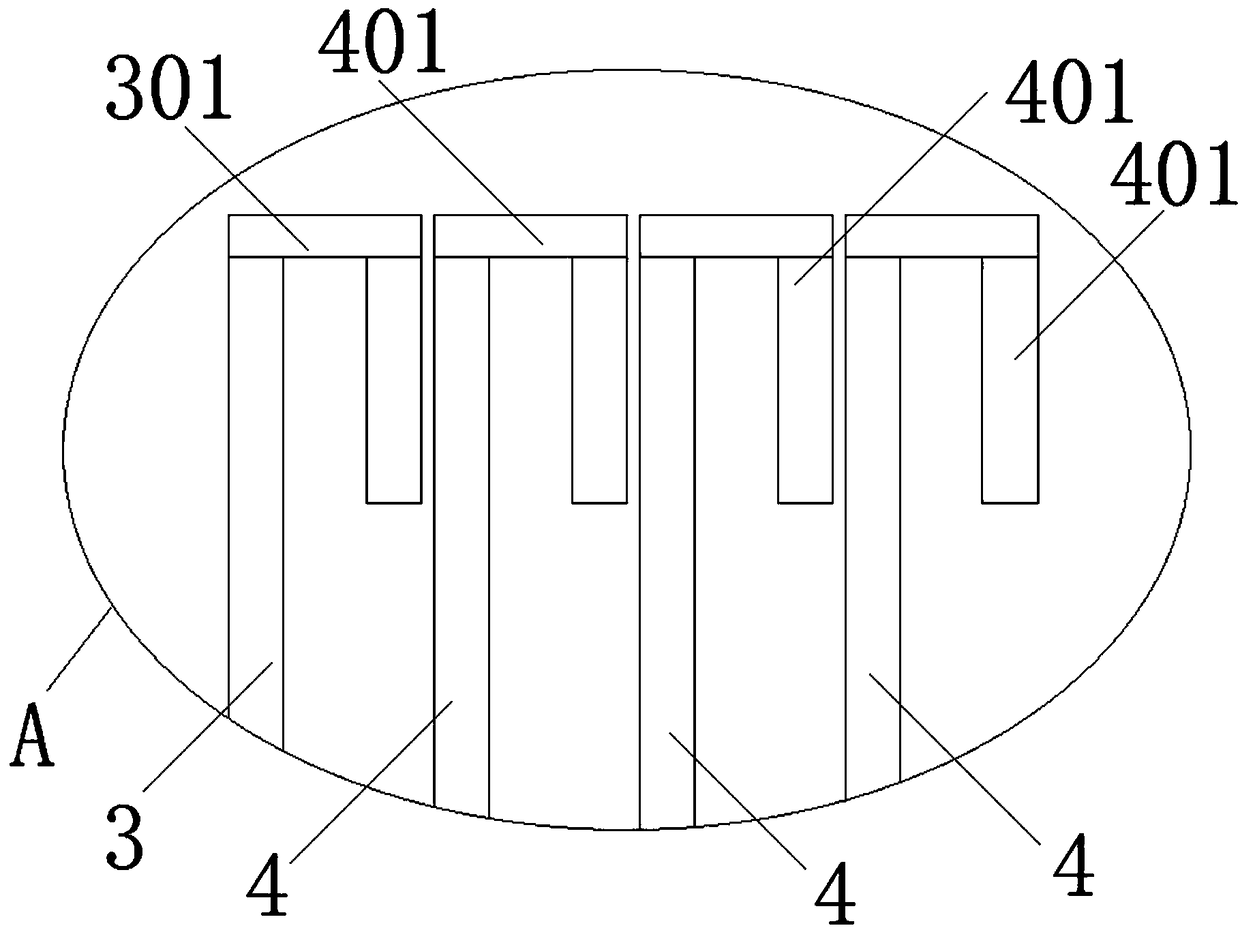

[0029] Such as figure 2 As shown, three second chimneys 4 are used, and the first chimney 3 and the second chimney 4 are all cylindrical cylinders or prismatic cylinders. The first chimney 3 and the three second chimneys 4 are sequentially socketed together. The "X"-shaped lifting device 5 raises the support plate 6, and the clamp 7 fixed on the support plate 6 drives the second chimney 4 on the outermost circle to rise, and the height of the chimney becomes higher, which improves the requirements for flue gas emission and realizes No pollution discharge.

specific Embodiment 2

[0030] Such as Figure 8 As shown, three second chimneys 4 are adopted, and the first chimney 3 and the second chimney 4 both adopt a conical cylinder or a conical cylindrical cylinder, and the first chimney 3 and the three second chimneys 4 are sequentially socketed together, The support plate 6 is raised by the "X"-shaped lifting device 5, and the clamp 7 fixed on the support plate 6 drives the second chimney 4 on the outermost circle to rise, the height of the chimney becomes higher, and the requirements for flue gas emission are improved. Realize pollution-free discharge.

[0031] Preferred:

[0032] Five or six or seven second chimneys 4 are adopted, the first chimney 3 and the second chimney 4 all adopt a conical cylinder or a conical cylindrical cylinder, and the first chimney 3 and five or six or seven second chimneys Two chimneys 4 are socketed together successively; Or adopt five or six or seven second chimneys 4, the first chimney 3, the second chimney 4 all adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com