Metal bridge transducer element and manufacturing method thereof

A manufacturing method and metal bridge technology, applied in the direction of offensive equipment, blasting barrels, weapon accessories, etc., can solve the problems of the influence of the metal bridge electric explosive device on the reliability, high decisiveness, and low production efficiency of the metal bridge electric explosive device. Artificial interference, to ensure the effect of accurate alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

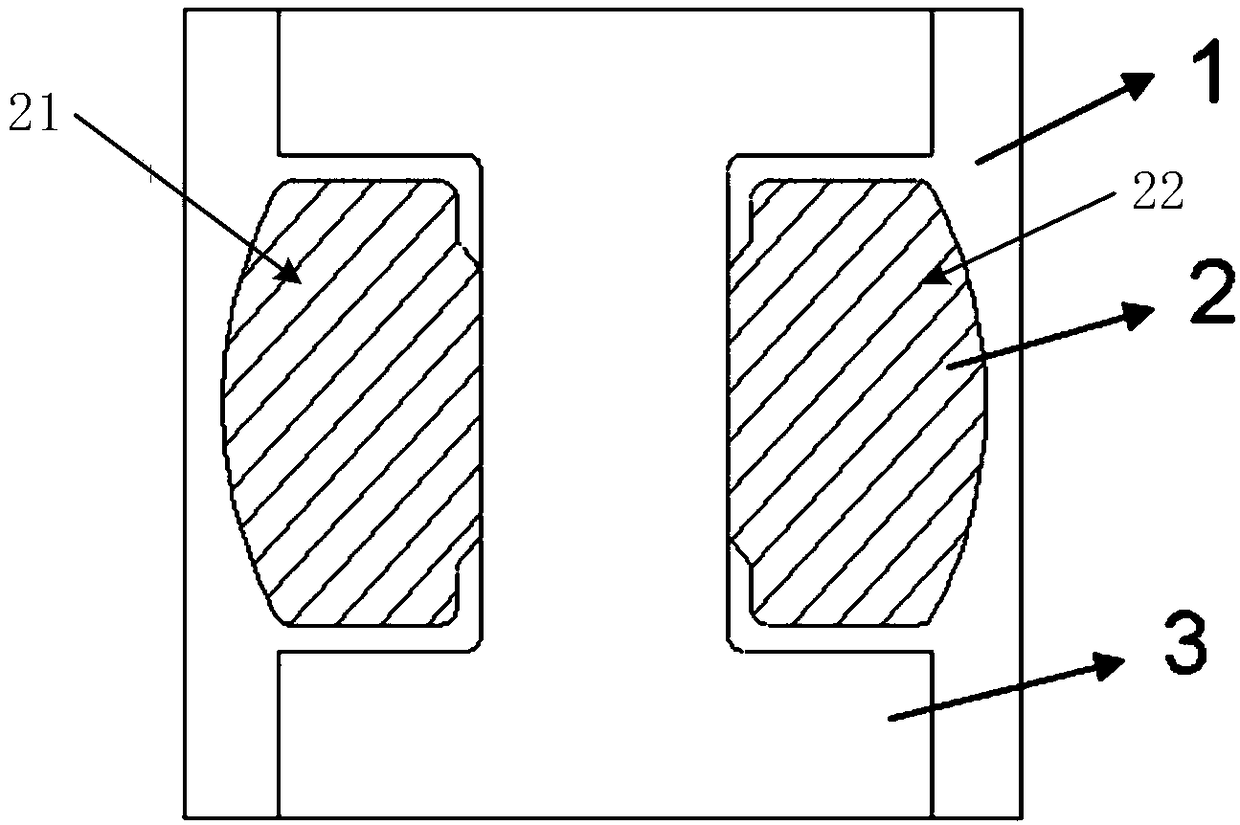

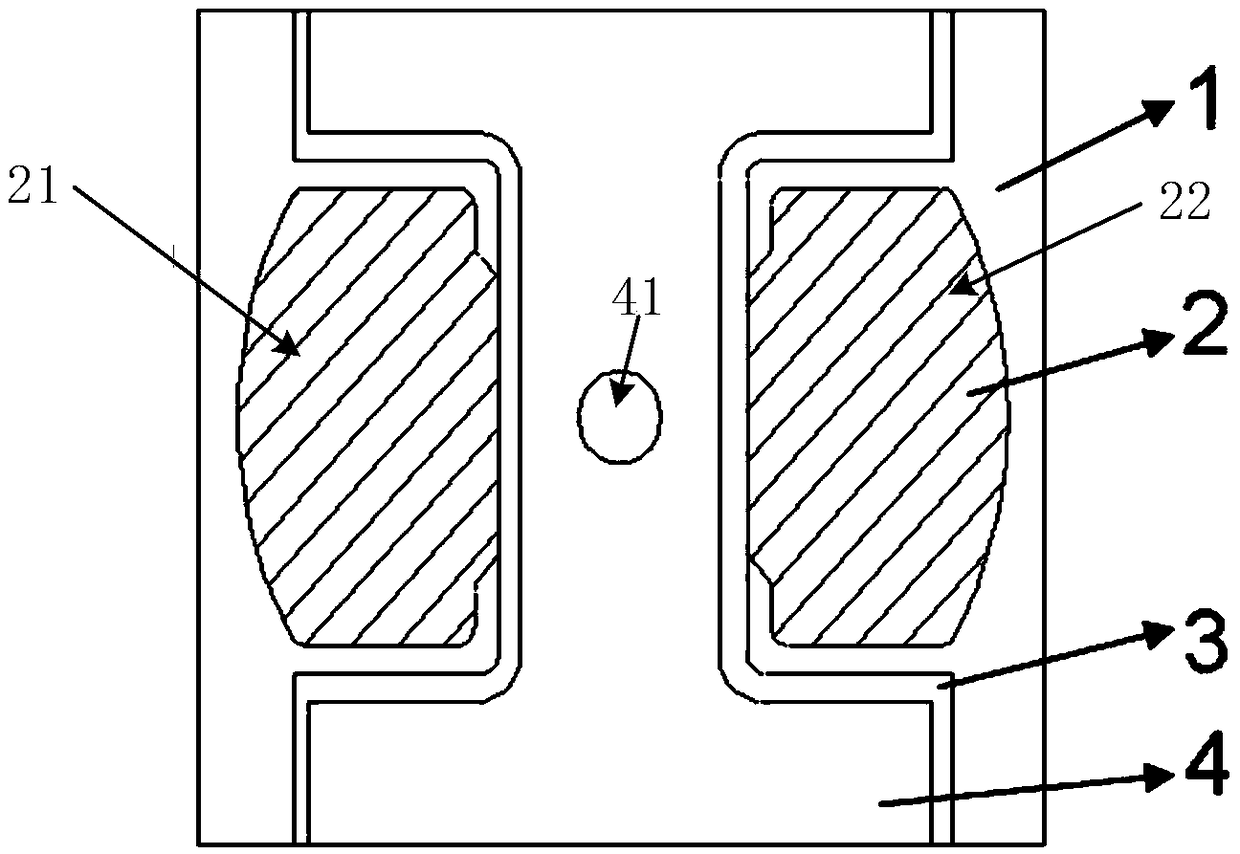

[0027] image 3 It is a schematic diagram of the structure and principle of the metal bridge transducer element provided by Embodiment 1 of the present invention. like image 3 As shown, the metal bridge transducer includes a substrate 1, a metal bridge layer 2 formed by adding metal materials on the surface of the substrate 1 through additive manufacturing technology, and passing through a part of the metal bridge layer 2 and a part of the substrate 1. The additive manufacturing technology increases the flying sheet layer 3 formed of non-metallic materials, and the accelerating chamber layer 4 formed of non-metallic materials is added on the flying sheet layer 3 through additive manufacturing technology. Specifically, the substrate 1 is a ceramic substrate or a glass-ceramic substrate, and the existing ceramic substrate products in the market can be directly used, or the ceramic substrate can be formed by using additive technology to obtain the substrate. The metal material...

Embodiment 2

[0032] Embodiment 2 is a manufacturing method of a metal bridge transducer, the method comprising the following steps:

[0033] Step (1), using acetone and deionized water to treat the surface of the substrate 1 through a standard cleaning process.

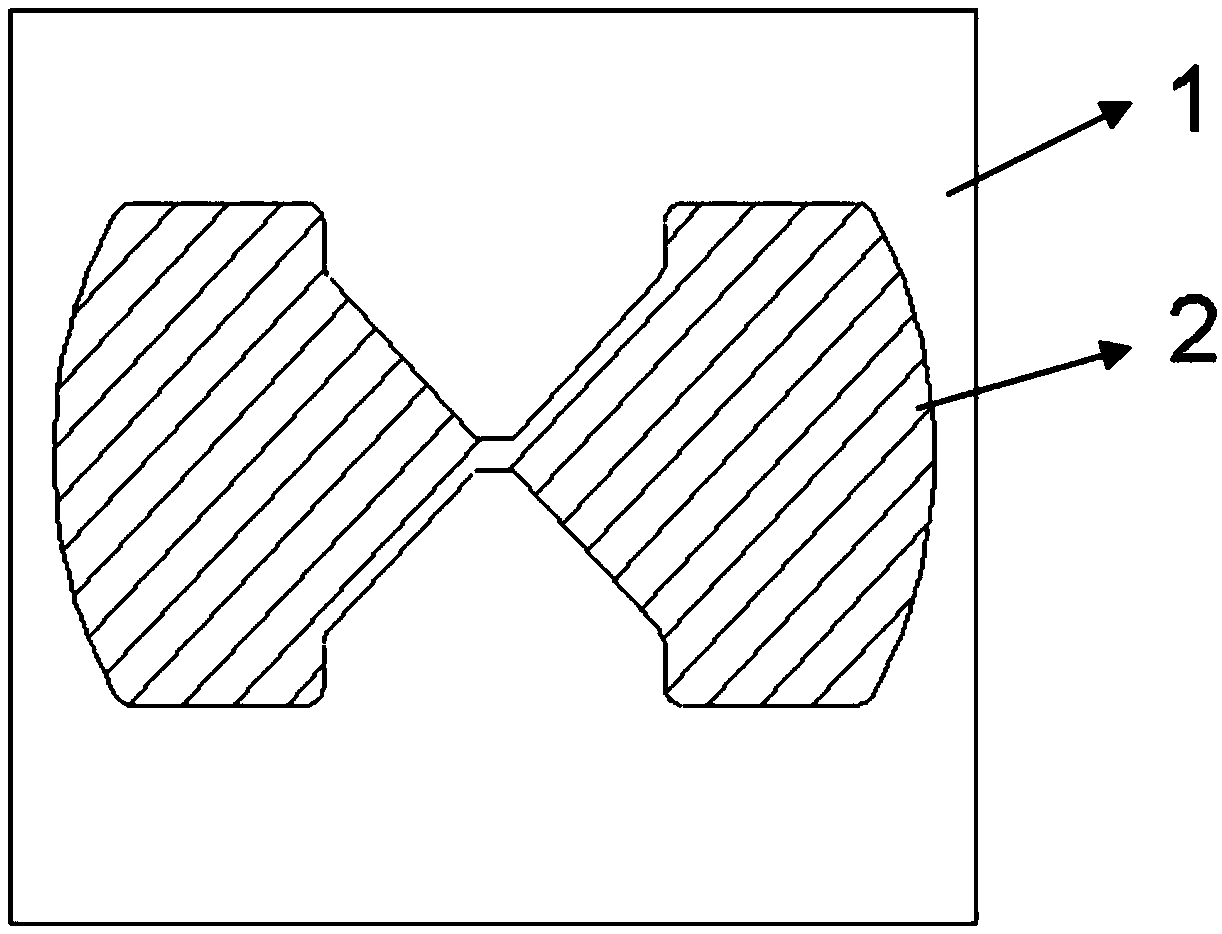

[0034] Step (2), such as figure 1 shown, according to figure 1 The shape of the metal bridge layer 2 in the metal bridge layer 2 is formed by additive manufacturing of the metal bridge shape on the surface of the substrate 1 . In this embodiment, the center part of the shape of the metal bridge is square, the length and width are 0.8 mm, and the thickness is 8 μm. In actual use, metal bridge shapes of other sizes can also be manufactured by additive technology. The size of the metal bridge can be are other sizes.

[0035] Step (3), such as figure 2 As shown, the non-metallic parylene material is added by additive manufacturing technology on a part of the metal bridge layer 2 and a part of the substrate 1 to form a flyer layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com