Firecracker igniting bracket

A technology of firecrackers and cylinders, which is applied in the field of machinery, can solve problems such as danger and easy explosion, and achieve the effect of convenient and safe use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

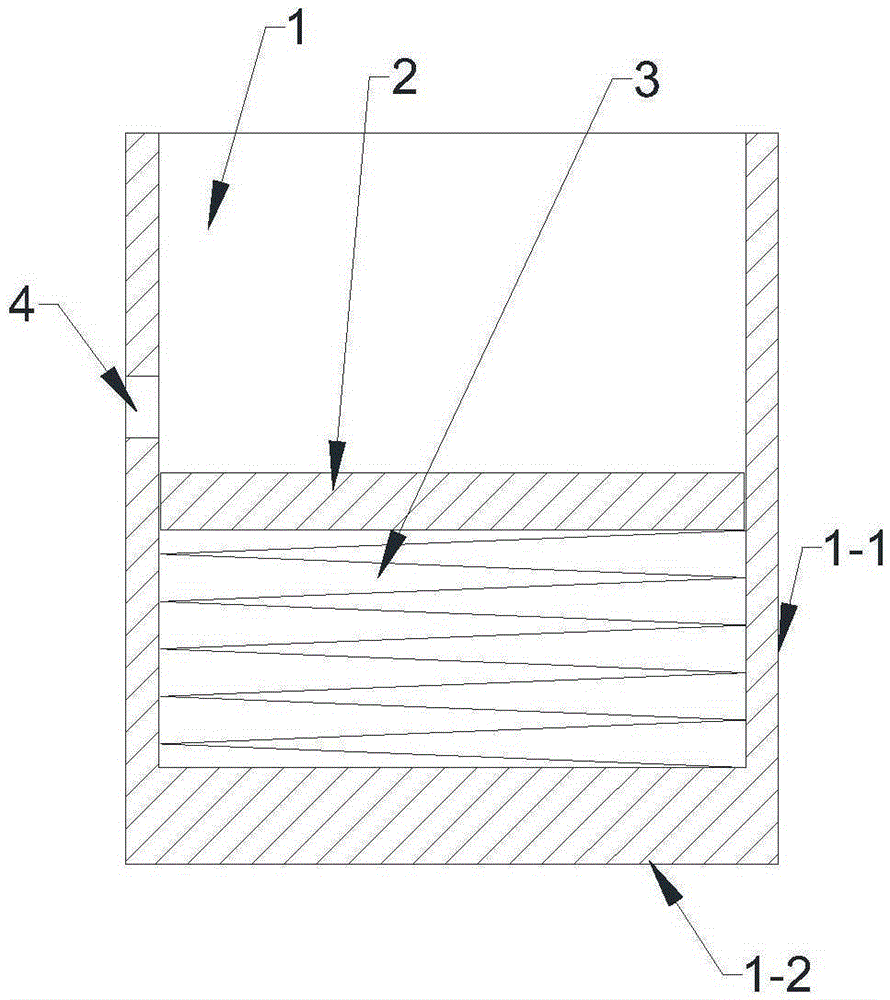

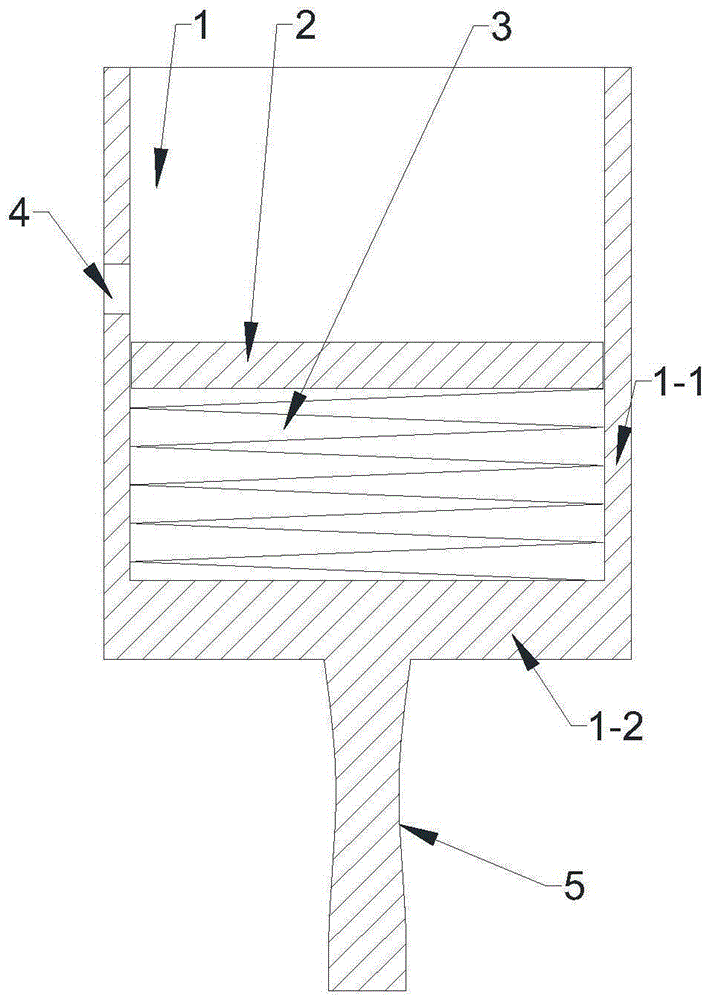

[0015] see figure 1 and figure 2 , a kind of point firecracker bracket of the present invention is characterized in that: adopt cylindrical seat 1, and adopt elastic member 3 to connect buffer plate 2 above the bottom plate 1-2 in cylindrical seat 1, the free height of elastic member 3 and The sum of the heights of the buffer plates 2 is less than half of the height of the cylinder base 1, and a lead hole 4 is provided on the cylinder wall 1-1 of the cylinder base 1 above the buffer plate 2.

[0016] The elastic member 3 is a spring or a shrapnel.

[0017] When in use, firecrackers are placed on the buffer plate 2 in the cylindrical seat 1, then the lead wire of the firecracker is passed through the lead wire hole 4, and the cylindrical seat 1 is held in hand to ignite the lead wire. The firecracker is supported by the buffer plate of the elastic member 3 2. The elastic buffer can reduce the damage of the opponent from the counter-impact force of firecrackers to a certain e...

Embodiment 2

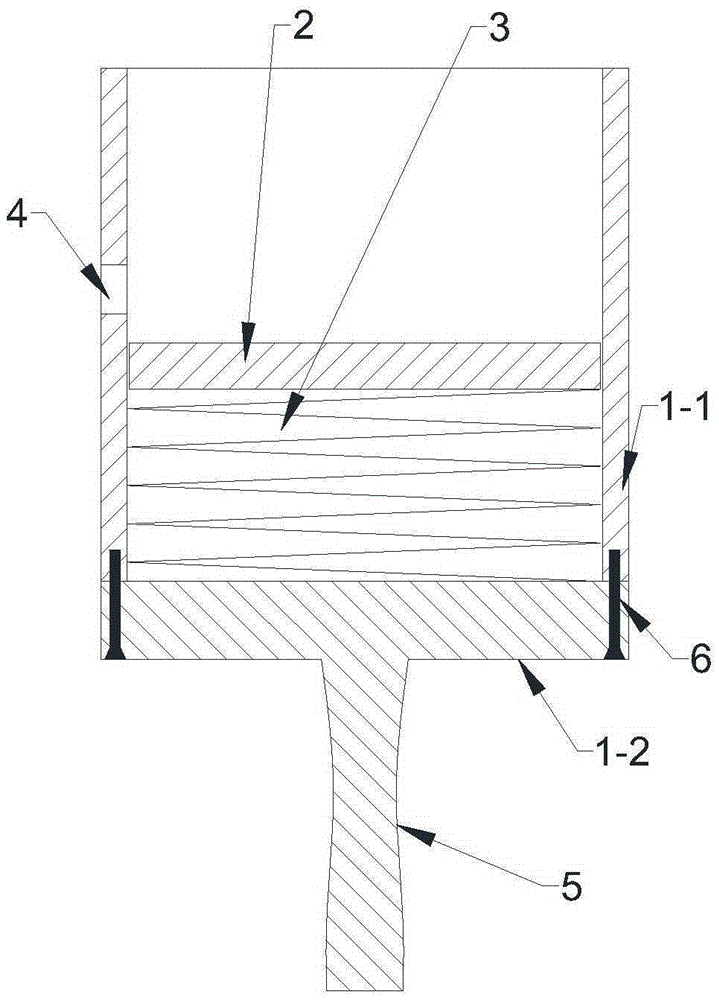

[0020] see image 3 The difference between this example and Embodiment 1 is that the bottom plate 1-2 of the cylindrical seat 1 and the cylindrical wall 1-1 adopt a separate assembly structure, and they are fixedly connected by fasteners 6 .

[0021] This design is to consider that after the buffer plate 2 is used for a long time, it is easy for garbage to enter between the buffer plate 2 and the bottom plate 1-2 of the cylindrical seat 1. By adopting a split assembly structure, people can unscrew the fastener 6 The bottom plate 1-2 is separated from the cylinder wall 1-1, so as to facilitate cleaning of garbage. After cleaning, it can be assembled again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com