Self-reset explosion-proof door

An explosion-proof door and self-returning technology, which is applied in mining equipment, earthwork drilling, mine/tunnel ventilation, etc., can solve problems such as long pressure relief time, failure to properly consider sealing problems, explosion-proof door explosion, etc., to overcome liquid Volatilization and freezing in winter, improving work efficiency and reliability, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

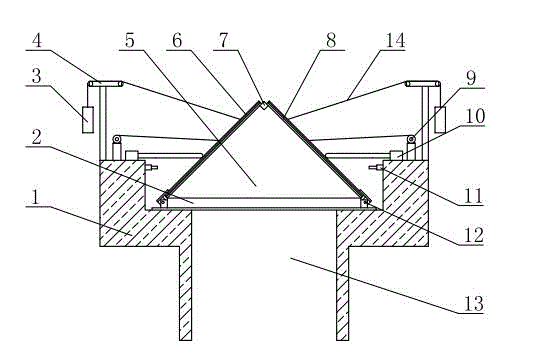

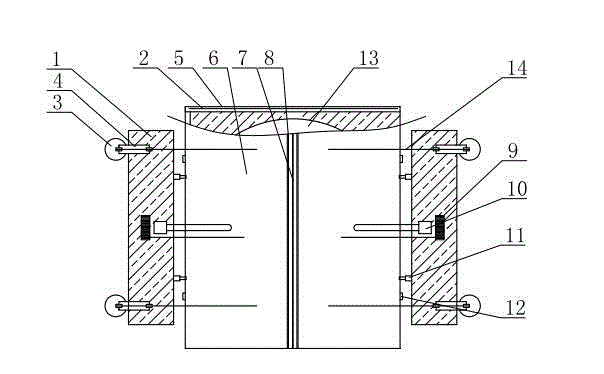

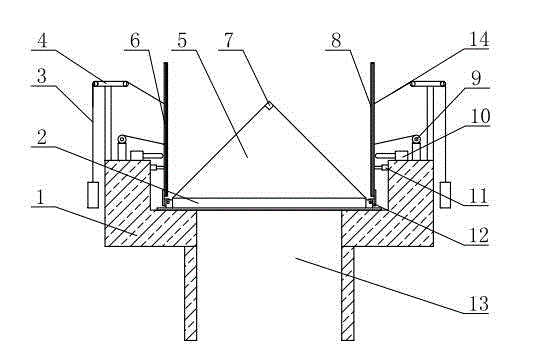

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0023] like Figure 1 to Figure 4 As shown, the square underframe 2 of the self-returning explosion-proof door according to the present invention is connected with the foundation base 1 through anchor bolts and welding, etc., and is located at the wellhead of the exhaust shaft 13, and the connection is sealed with cement. In order to prevent air leakage; the isosceles triangular vertical plate 5 is vertically welded on the front and rear sides of the square underframe 2, and the outside is reinforced with ribs, and the weld seam needs to be sealed; the cross beam 7 is used to connect the top corners of the triangular vertical plates 5 on both sides, which can effectively Prevent deformation of the riser. The door panel 6 is hinged on the edge of the square base frame 2 through the hinge 12; the door panel 6 is rectangular, one on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com