An insulated butt jointing machine for pulling the live current on both sides

A technology of docking machine and connecting rod, applied in the direction of overhead line/cable equipment, etc., can solve the problem of live disconnection, etc., and achieve the effect of reducing dangerous points, avoiding insufficient safety distance, and improving the scope of operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

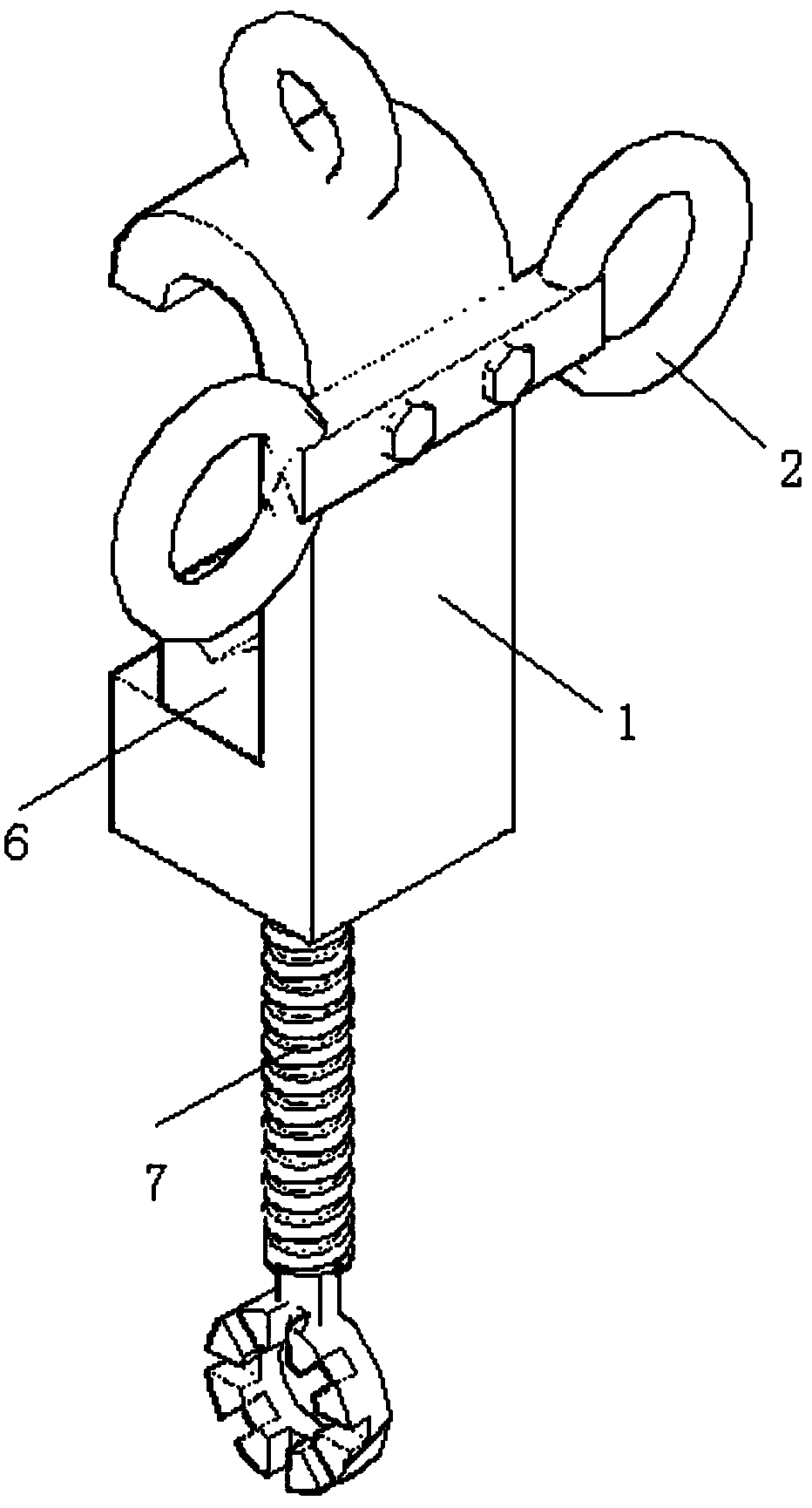

Embodiment 1

[0028] Provided is an insulation butt joint machine for drawing and draining current on both sides, comprising a first chuck and a second chuck. The first chuck includes an arc-shaped body for locking and a fixing ring arranged on the back of the arc-shaped body , The fixing ring is arranged on the side close to the second chuck; the second chuck includes an arc-shaped body for locking and a steering member arranged on the back of the arc-shaped body, and the steering member is located on the side near the first chuck. A pulley is arranged on the side, and one end of an insulated pull rope is fixed on the fixed ring, and passes through the pulley of the second chuck to form the insulated butt joint machine.

[0029] When conducting live disconnection and drainage operations, the arc-shaped body of the first chuck locks one end for drainage, and the arc-shaped body of the second chuck locks the other end for drainage. By pulling the free ends of the insulated drawstrings, the live ...

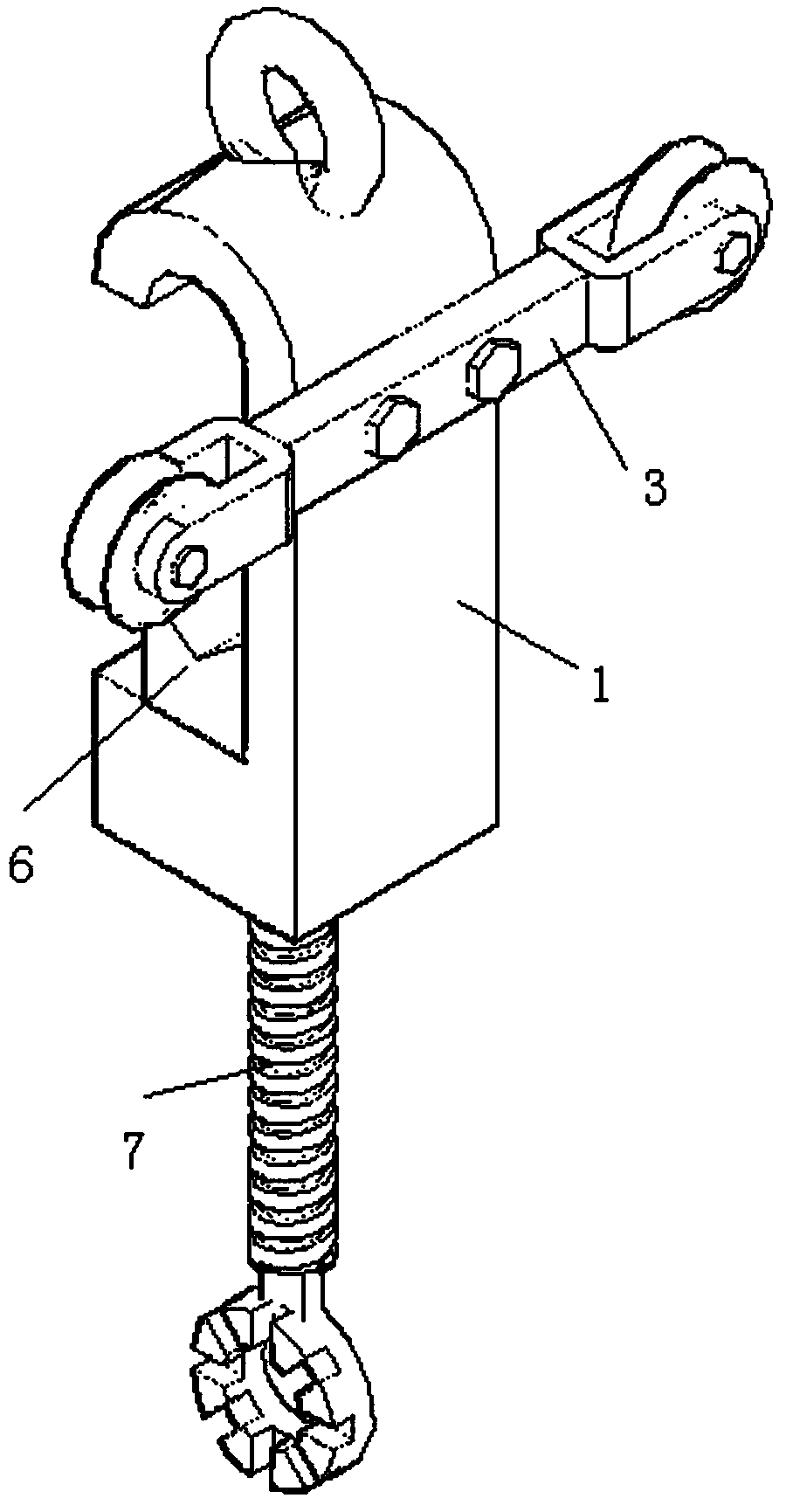

Embodiment 2

[0031] An insulated butt jointing machine used to draw current on both sides of the electric current, comprising a first chuck and a second chuck, the first chuck includes an arc-shaped body for locking and a fixing ring arranged on the back of the arc-shaped body, The first chuck is also provided with a "7"-shaped plate, the "7"-shaped plate and the arc-shaped body of the first chuck form a fixing clip, a pulley is arranged in the fixing clip, and the fixing ring is fixed on the "7"-shaped plate The second chuck includes an arc-shaped body for locking and a steering member arranged on the back of the arc-shaped body. The steering member is provided with a pulley on the side close to the first chuck, and one end of an insulating pull rope is fixed in On the fixed ring, the pulley passing through the second chuck, and then passing through the pulley in the fixing clip, forms the insulation butt joint machine.

[0032] When conducting live disconnection and drainage operations, the...

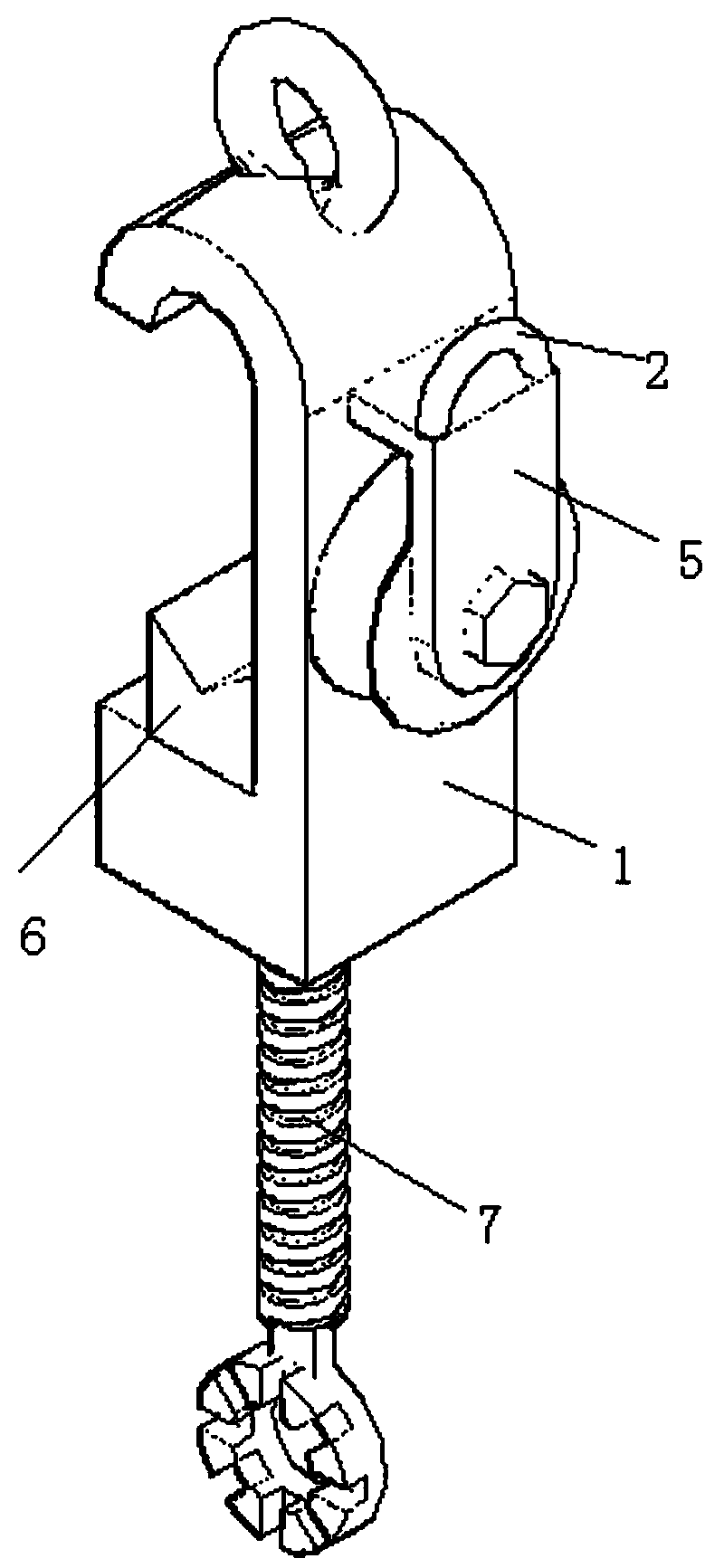

Embodiment 3

[0034] An insulated butt jointing machine used to draw current on both sides of the electric current, comprising a first chuck and a second chuck, the first chuck includes an arc-shaped body for locking and a fixing ring arranged on the back of the arc-shaped body, The fixing ring is arranged on the side close to the second chuck; the second chuck includes an arc-shaped body for locking and a two-way steering member arranged on the back of the arc-shaped body. Both ends of the two-way steering member are set as pulleys. The pulleys at both ends of the steering member are set on the back of the arc-shaped body of the second chuck by a fixing rod, the fixing rod is fixed on the back of the arc-shaped body of the second chuck by a bolt, and one end of an insulating pull rope is fixed on the fixing ring, Passing through the pulley on the side of the second chuck close to the first chuck, the insulation butting machine is formed.

[0035] When conducting live disconnection and drainag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com