Motor front end cover provided with temperature sensor mounting joint

A temperature sensor and joint installation technology, which is applied in the field of electric motors, can solve the problems of not being able to know the temperature changes of the bearings in time, and the running conditions of the bearings, etc., and achieve the effects of saving mold costs, shortening the manufacturing cycle, and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

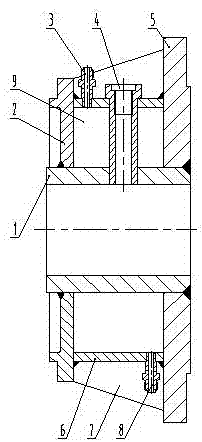

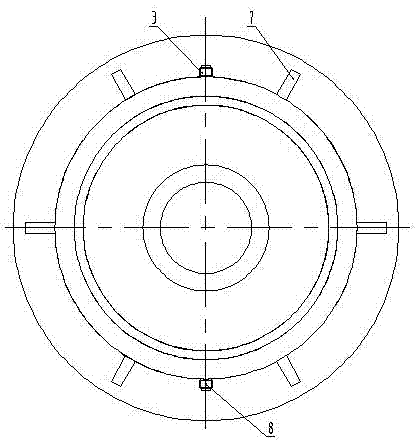

[0018] The front end cover of the motor with the temperature sensor installation joint shown in the attached drawing includes bearing housing 1, cover plate 2, outer ring 6, flange 5, induction device installation joint 4; cover plate 2, outer ring 6, flange The flange 5 is set on the bearing seat sleeve 1 in sequence, the cover plate 2 and the flange 5 are welded and connected to the outer wall of the bearing seat sleeve 1, and the outer ring 6 is fit on the bearing seat sleeve 1 with gaps; the end faces of the outer ring 6 and the cover respectively Plate 2 and flange 5 end faces are welded and connected to form a disc structure with an inner cavity interlayer 9; the induction device installation joint 4 is a bush-shaped component, which penetrates the outer ring 6, inner cavity interlayer 9, and bearing seat sleeve 1 radially from out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com