Multidirectional logistics sorting and steering device

A steering device, multi-directional technology, applied in sorting and other directions, can solve the problems of easy sorting errors in manual sorting time, rigid impact of sorting items, poor maintenance convenience, etc., to increase the effective transmission contact area and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

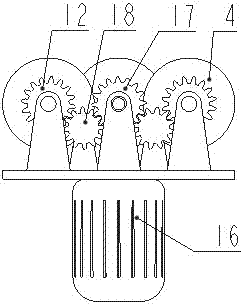

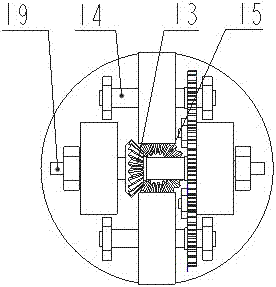

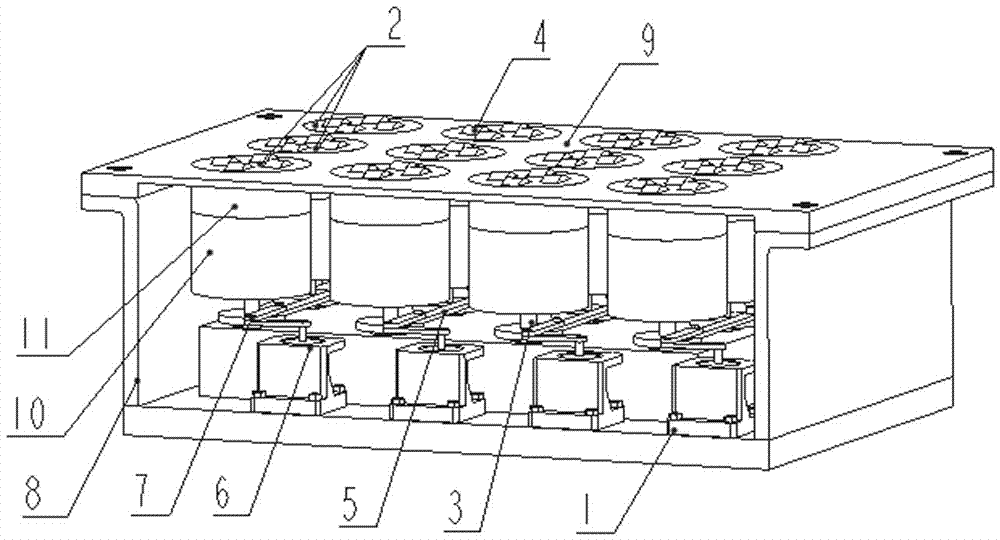

[0015] Such as figure 1 , Figure 4 As shown, the present invention includes a base 1, a steering drum 2, a side mounting plate 8, and an upper cover plate 9. The base 1 is provided with a plurality of turning roller groups, and each turning roller group is composed of three turning rollers 2 whose centerlines are located in the same plane. The bottom of the steering drum 2 is supported on the base 1 through a vertical rotating shaft 3 . Three steering drums 2 in each steering drum group are connected by steering connecting rods 5, and then connected with corresponding steering motors 6 through a rocker mechanism 7 to form a drum steering mechanism. Steering motor 6 drives the drum steering mechanism to make the three steering drums 2 in the group rotate in the same direction, angle and speed. By controlling the rotation angle and speed of the steering motor 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com