Clamping method of tube workpiece clamp

The technology of a workpiece fixture and clamping method is applied in the direction of clamping devices, manufacturing tools, metal processing machinery parts, etc., which can solve the problems of manpower tightening and damage to objects, so as to ensure accurate clamping and avoid virtual contact or clamping force Insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be described in more detail below in conjunction with specific embodiments and accompanying drawings.

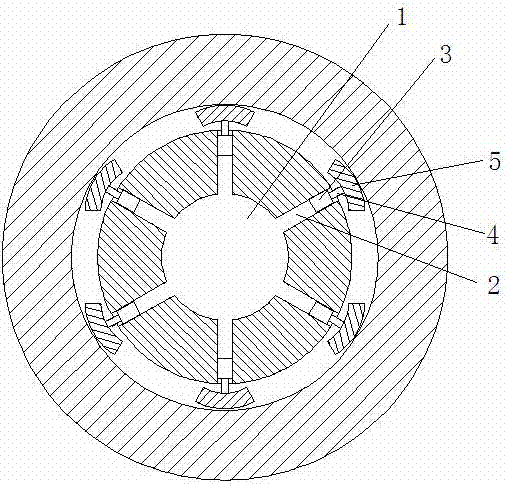

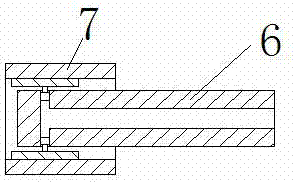

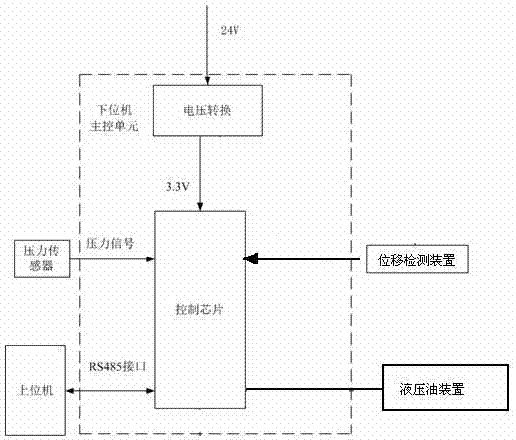

[0039] Such as figure 1 As shown, a fixture clamping method for pipe workpieces, the fixture includes a connecting shaft, a hydraulic oil device, a hydraulic diameter expanding mechanism, a displacement detection device, a pressure detection device and a host computer, wherein one end of the connecting shaft is connected to the machine tool The main shaft is connected, and the other end of the connecting shaft is evenly equipped with multiple hydraulic diameter expanding mechanisms along the circumference of the connecting shaft on the same plane, and the multiple hydraulic expanding mechanisms are supported on the inner side wall of the workpiece to support and clamp the workpiece; A main oil passage and several oil passage units connected with the main oil passage are provided in the axial direction of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com