Linkage clamping multi-profile mechanism

A multi-profile, linkage technology, applied in the direction of clamping devices, clamping, metal processing machinery parts, etc., can solve the problem of single clamping objects, achieve the effects of reducing equipment costs, improving labor efficiency, and ensuring positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further explained below in conjunction with the drawings.

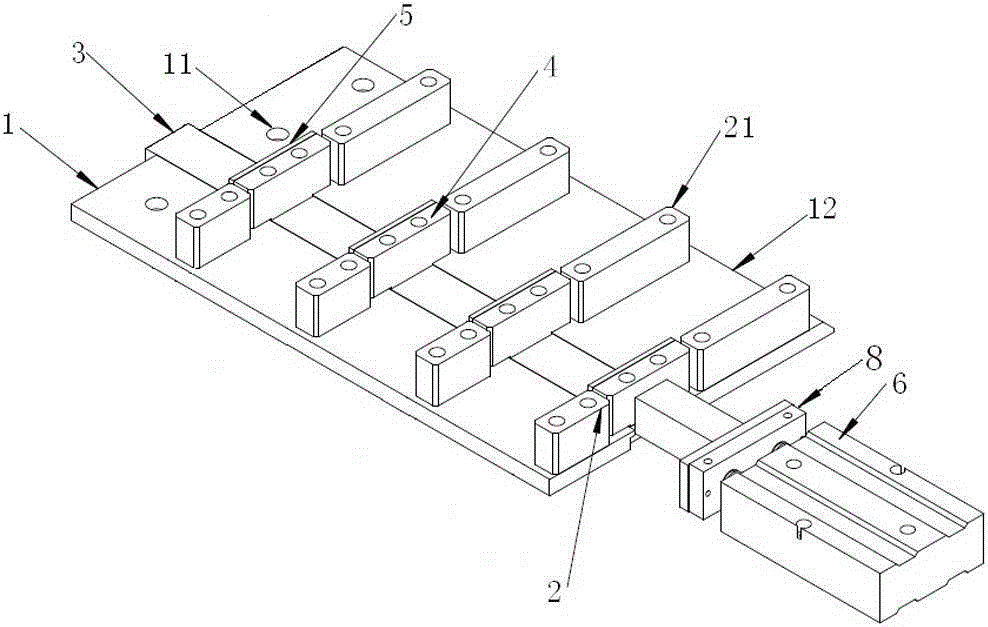

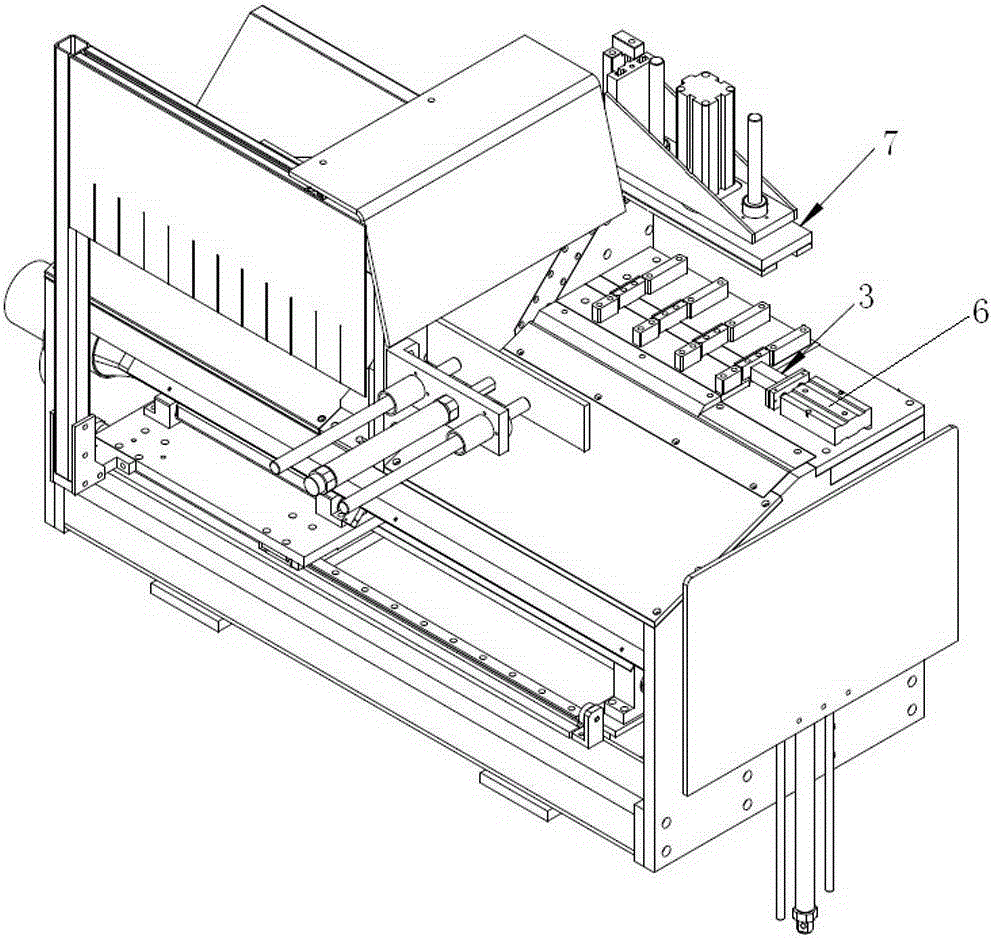

[0011] Such as figure 1 , figure 2 As shown, the linkage clamping multi-profile mechanism of the present invention includes a lower base plate A1, a lower base plate B12, a positioning block A2, a positioning block B21, a sliding block 3, a clamping block 4, a tendon 5, and a flat biaxial cylinder 6和连接件8.

[0012] When using the present invention, a slider 3 is provided in the middle of the lower bottom plate A1 and the lower bottom plate B12, and the upper part of the slider 3 is provided with a clamping block 4. According to the different sizes of the processed profile, the clamping block 4 and the clamping The distance between the blocks 4, the two sides of the sliding block 3 are respectively provided with positioning blocks A2 and positioning blocks B21, and the positioning pin holes 11 are machined on the lower base plate A1 and the lower base plate B12 for installation accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com