High temperature-resistant sealant composition, high temperature-resistant sealant tape and preparation method thereof

A sealing tape and sealant technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, aldehyde/ketone condensation polymer adhesives, etc., can solve damage, increase mold cleaning burden, and affect vacuum Problems such as bag sealing performance, to solve the effect of high temperature thinning and sticking mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0023] According to a preferred embodiment of the present invention, the mixing method is to mix the main resin, the telechelic polymer and the filler uniformly first, and then add the vulcanizing agent and the accelerator and mix uniformly.

[0024] According to the preparation method of the high temperature resistant sealing tape provided by the invention, the preparation method comprises:

[0025] Step S1: adding the main resin, telechelic polymer and filler into the internal mixer, and banburying at 60-100°C;

[0026] Step S2: Lower the banburying temperature in S1 to below 40°C, add vulcanizing agent and accelerator, fully mix and discharge;

[0027] Step S3: compressing the material discharged in step S2, cutting it into strips and attaching a release paper to obtain the sealing tape. The size of the sealing strip can be adjusted according to actual needs, and the usual size can be, thickness: 3±0.2mm, width: 12±0.2mm.

[0028] Among them, in step S1, tackifiers, auxil...

Embodiment 1~7

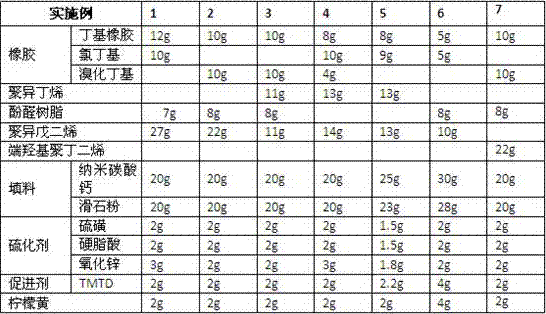

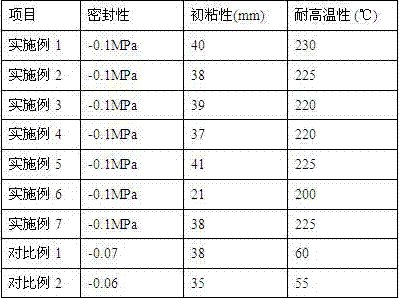

[0033] The composition and dosage of the sealing tape in this example are shown in Table 1.

[0034] The production process is as follows: 1) The main rubber and the teleclaw polymer are kneaded and thinned 30 times, and the tablets are produced; 2) The mixture in step 1) is weighed and put into the internal mixer at 100 degrees for 30 minutes, 3 ) Weigh the phenolic resin as needed and put it into the internal mixer and banbury together at 100°C for 10 minutes; 4) Weigh other materials except vulcanizing agent and accelerator and gradually add them to the internal mixer within 30 minutes, 5 ) Continue banburying for 10 minutes after adding, and then cool down the mixer to below 40°C within 30 minutes. 6) Weigh the vulcanizing agent and accelerator and put them in the mixer, and continue banburying for 30 minutes to discharge. 7) The resulting semi-finished product was compressed by a double-roller tablet machine and cut into strips to obtain a sample of the sealing tape of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com