Wheel hub automatic balancing process

An automatic dynamic balance and wheel hub technology, applied in the field of wheel hub quality inspection, can solve the problems affecting the efficiency of testing, labor and other issues, and achieve the effect of improving testing efficiency, high testing accuracy, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

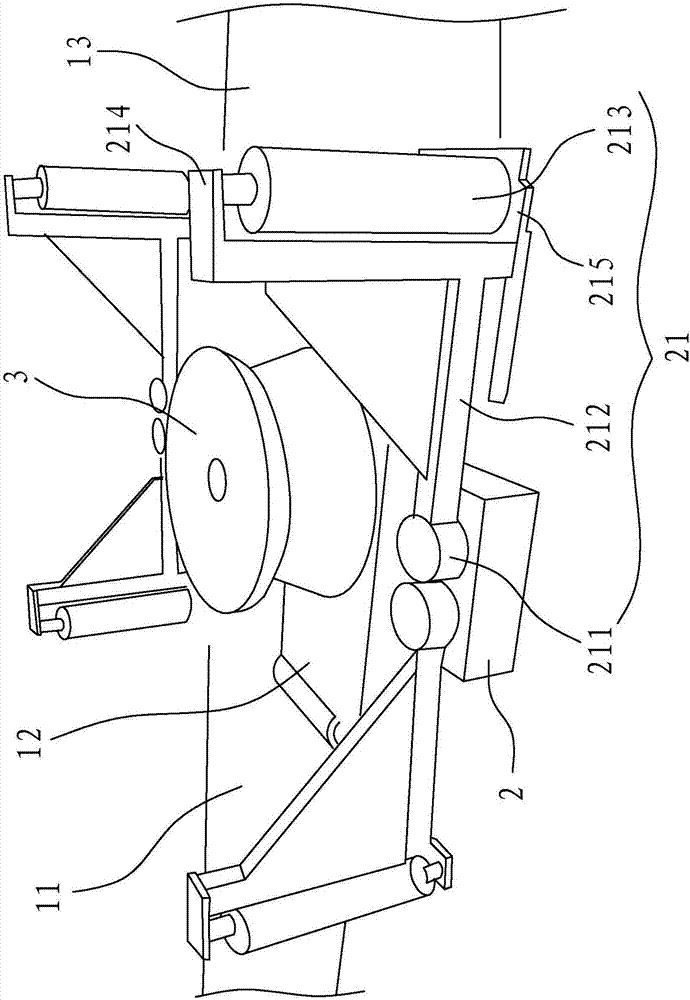

[0026] Such as figure 1 As shown, a kind of wheel hub automatic dynamic balancing process that the present invention relates to comprises the following steps:

[0027] ① The hub 3 to be tested is transported to the auxiliary transport mechanism 12 by the first transport mechanism 11, and the wheel hub 3 to be tested is transported to the middle position by the auxiliary transport mechanism 12;

[0028] The first conveying mechanism 11, the auxiliary conveying mechanism 12 and the following second conveying mechanism 13 are all powered by motors, using belts or rollers to form power, and mainly play a role in conveying. This conveying mechanism is a conventional mechanism. , its detailed structure will not be elaborated here;

[0029] ②Under the action of the centering mechanism 2, let the hub 3 to be tested be in the center position;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com