Biological type hip joint

A hip joint, bio-based technology, applied in the direction of hip joints, joint implants, joint implants, etc., can solve the problems of affecting function, uneven elastic modulus, large difference in unevenness, etc., and achieve hooking effect Compact and reliable, good structural mechanical properties, and the effect of preventing excessive load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

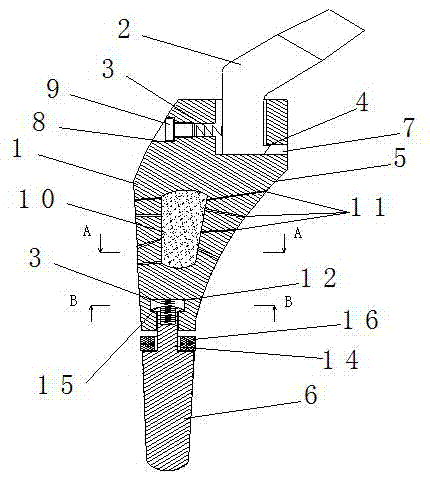

[0031] As attached Figure 1-4 As shown, a biological hip joint includes a femoral stem 1, a femoral neck 2, a spring 3, and a cushion 16; the lower part of the femoral neck 2 is in the shape of a positive cylinder, and the upper part is set as a bias inclined column, and the femur The lower side of the neck 2 is provided with a barb 4; the femoral stem 1 is split into an upper part 5 and a lower part 6; the upper part 5 of the femoral stem 1 is provided with an L-shaped through hole 7 and a longitudinal hole in the L-shaped through hole 7 The connecting mounting hole 8; the lower part of the femoral neck 2 is inserted into the L-shaped through hole 7, and the barb 4 is hooked into the transverse hole in the L-shaped through hole 7; the mounting hole 8 is additionally provided with a spring 3, the spring 3 One end is against the lower part of the femoral neck 2, and the outer side of the other end is additionally provided with a screw 9 connected to the mounting hole 8; the uppe...

Embodiment 2

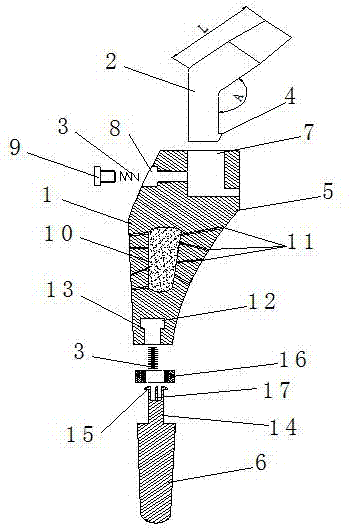

[0043] As attached Figure 5-6 As shown, a biological hip joint includes a femoral stem 1, a femoral neck 2, a spring 3, and a cushion 16; the lower part of the femoral neck 2 is in the shape of a positive cylinder, and the upper part is set as a bias inclined column, and the femur The lower side of the neck 2 is provided with a barb 4; the femoral stem 1 is split into an upper part 5 and a lower part 6; the upper part 5 of the femoral stem 1 is provided with an L-shaped through hole 7 and a longitudinal hole in the L-shaped through hole 7 The connecting mounting hole 8; the lower part of the femoral neck 2 is inserted into the L-shaped through hole 7, and the barb 4 is hooked into the transverse hole in the L-shaped through hole 7; the mounting hole 8 is additionally provided with a spring 3, the spring 3 One end is against the lower part of the femoral neck 2, and the outer side of the other end is additionally provided with a screw 9 connected to the mounting hole 8; the upp...

Embodiment 3

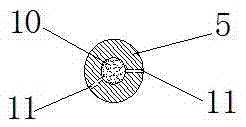

[0055] As attached Figure 7 As shown, a biological hip joint includes a femoral stem 1, a femoral neck 2 and a spring 3. The lower part of the femoral neck 2 is in the shape of a positive cylinder, the upper part is set as a bias inclined column, and the lower part of the femoral neck 2 is one The side is provided with a barb 4; the upper part of the femoral stem 1 is provided with an L-shaped through hole 7 and a mounting hole 8 communicating with the longitudinal hole in the L-shaped through hole 7; the lower part of the femoral neck 2 is inserted into the L-shaped through hole 7 , And the barb 4 is hooked into the transverse hole in the L-shaped through hole 7; a spring 3 is added in the mounting hole 8, one end of the spring 3 is against the lower part of the femoral neck 2, and the other end is additionally connected to the mounting hole 8. The screw 9; the femoral stem 1 is provided with a filling sandwich 10 that penetrates both sides of the stem body, and a perforation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com