Offshore wind power high-piled cap foundation berthing system and construction method

A high-pile cap, offshore wind power technology, applied in infrastructure engineering, climate change adaptation, shipping equipment, etc., can solve problems such as deformation of steel bars, lateral tension damage of fenders, and large displacement space of fenders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

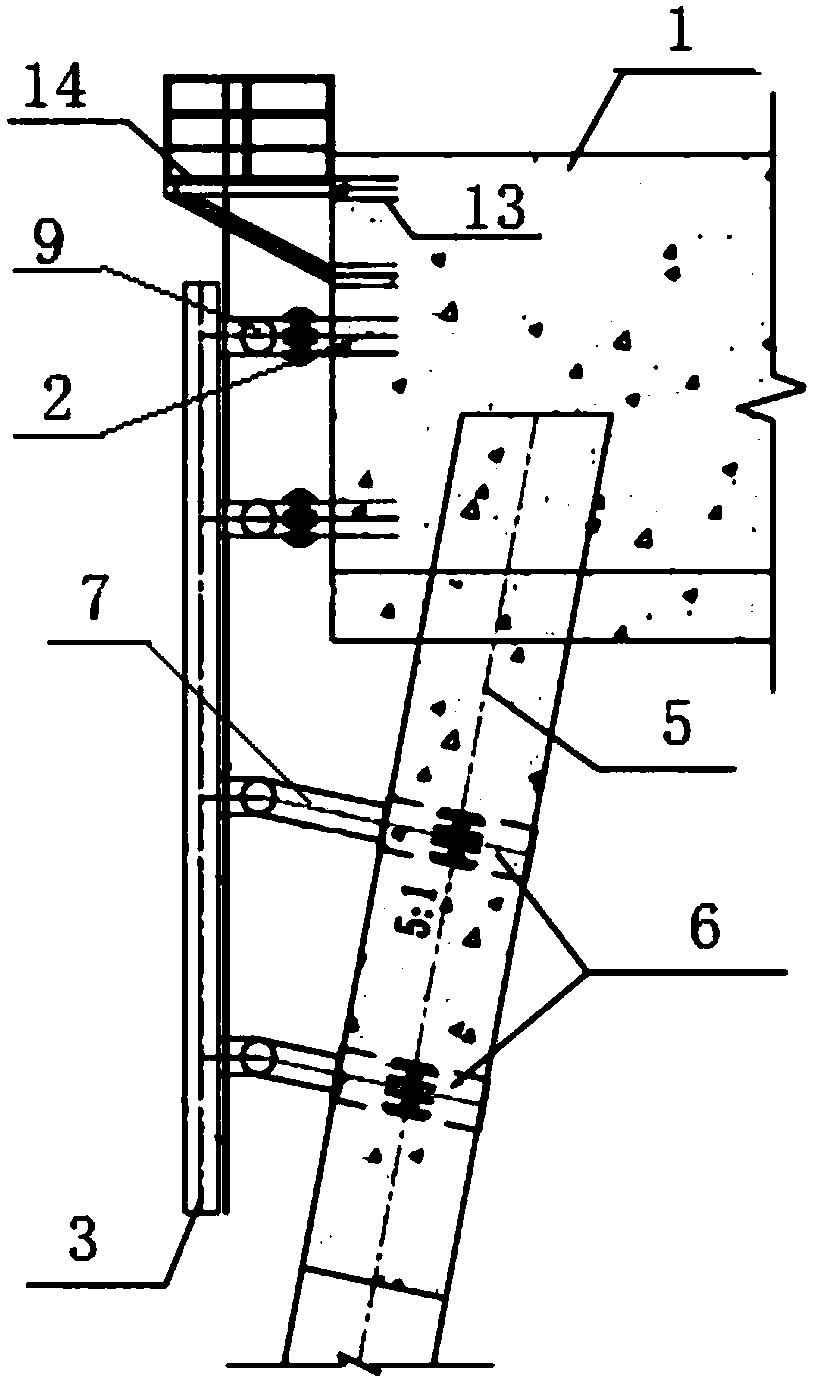

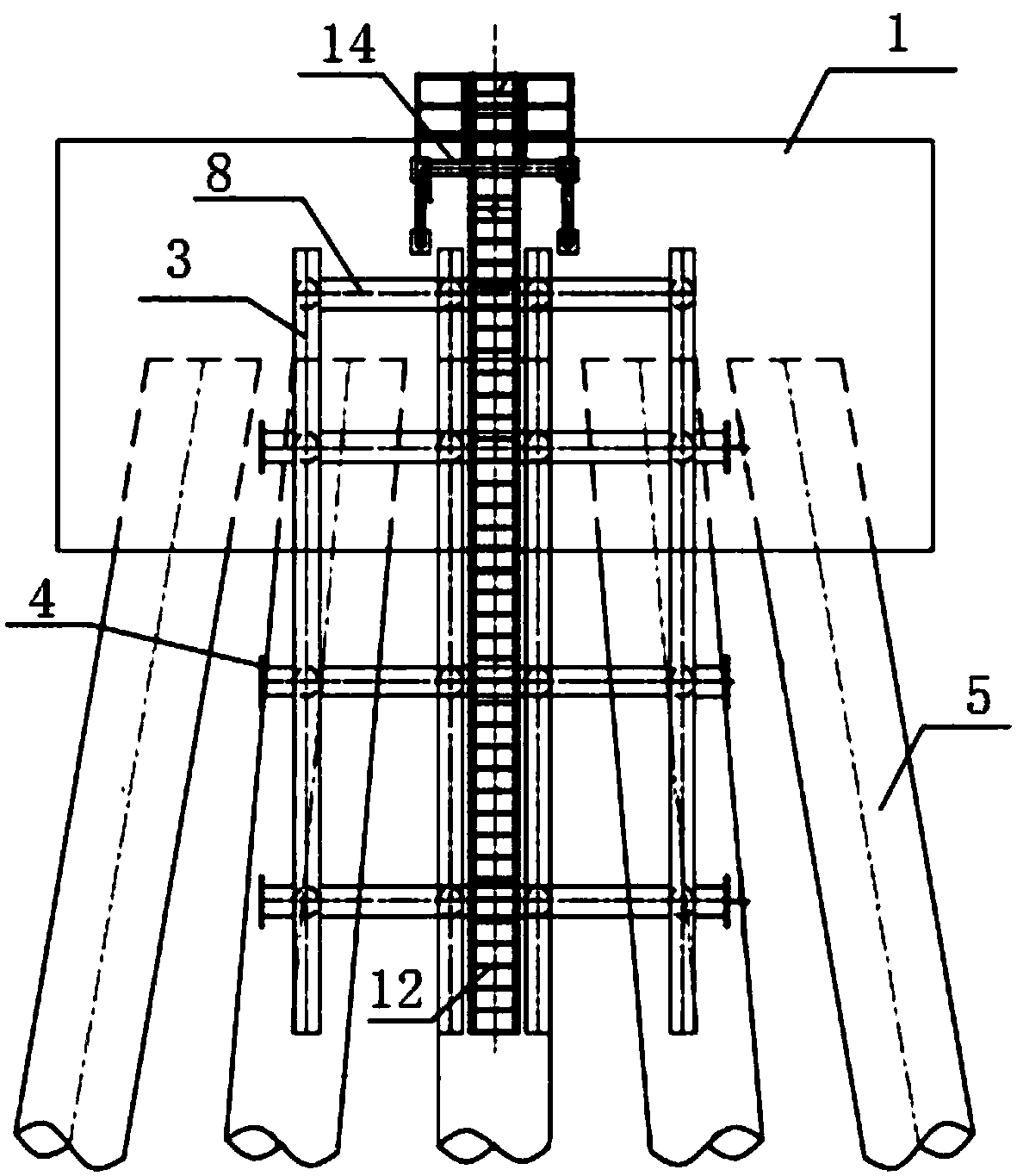

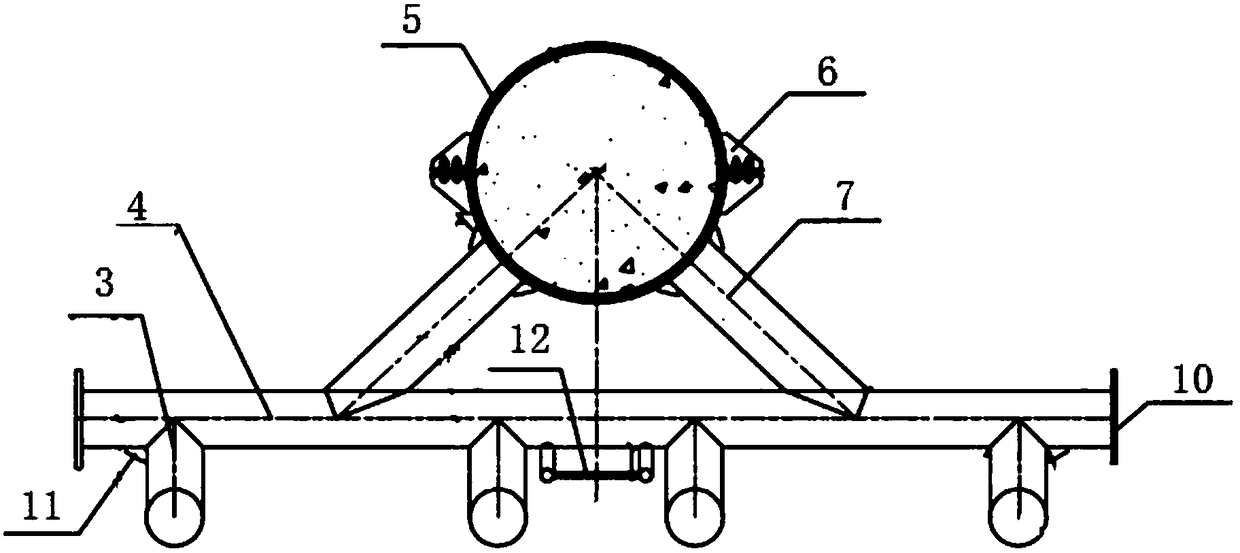

[0033] see figure 1 , figure 2 , image 3 , is an offshore wind power high pile cap foundation berthing system provided by an embodiment of the present invention, such as figure 1 , figure 2 , image 3 As shown, the system includes a concrete cap 1, and the upper and lower parts of the concrete cap 1 are pre-embedded with a plurality of pre-embedded caps 2;

[0034] a ship berth member, the ship berth member comprising a plurality of ship berth steel pipes 3 arranged vertically and bollards 4 fixedly connected to the plurality of ship berth steel pipes 3 arranged horizontally;

[0035] The upper part of the berth steel pipe 3 is fixedly connected to the embedded part 4 of the platform by welding process, and the lower part is connected to the fan steel pipe column 5 through a supporting structure;

[0036] The supporting structure includes a hoop assembly 6 arranged on the fan steel pipe column 5 and a first connecting steel pipe 7 whose two ends are respectively welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com