Composite hip joint

A hip joint and femoral stem technology, applied in the field of compound hip joints, can solve problems such as uneven distribution of elastic modulus, limited multi-level pore materials, and inability to overgrown human tissue, achieve good structural mechanical properties, and speed up postoperative recovery. long-term, good effect of growing into the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

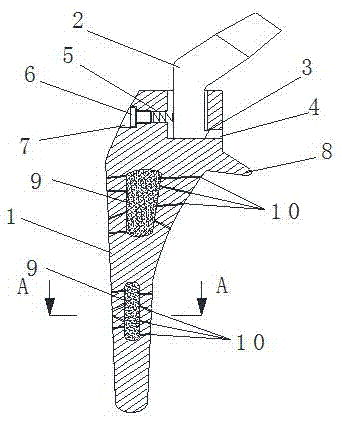

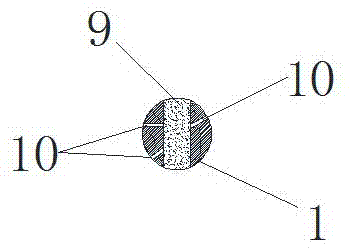

[0029] As attached to the manual Figure 1-3As shown, a compound hip joint includes a femoral stem 1, a femoral neck 2, a spring 5 and a screw rod 6; The lower part is provided with a barb 3; the head of the femoral stem 1 is provided with an L-shaped through hole 4, and a mounting hole 7 communicating with the longitudinal hole in the L-shaped through hole 4; the lower part of the femoral neck 2 is inserted into the L-shaped through-hole 4. in the L-shaped through hole 4, and the barb 3 is hooked in the transverse hole in the L-shaped through hole 4; a spring 5 is arranged in the installation hole 7, and one end of the spring 5 is against the lower part of the femoral neck 2, and the other end is provided on the outside of the The screw rod 6 in the mounting hole 7; the middle part of the handle body of the femoral stem 1 is provided with a tapered protrusion 8 on the side close to the femoral neck 2; The filling interlayer 9, and the perforation 10 that runs through the han...

Embodiment 2

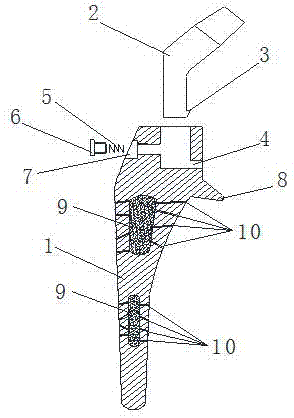

[0041] As attached to the manual Figure 4 As shown, a compound hip joint includes a femoral stem 1 and a femoral neck 2; the lower part of the femoral neck 2 is in the shape of a positive cylinder as a whole, the upper part is set as an offset inclined column, and the lower end of the femoral neck 2 is composed of two parts , a part of which is an elastic barb 3, and the other part is a columnar body, and an interval gap is provided between the elastic barb 3 and the columnar body; an L-shaped through hole 4 is provided in the head of its femoral stem 1; its femoral neck 2 The lower part of the femoral stem 1 is inserted into the L-shaped through hole 4, and the elastic barb 3 is hooked into the transverse hole in the L-shaped through hole 4; Protrusion 8; the middle part and the lower part of the handle body of the femoral handle 1 are respectively provided with filling interlayers 9 passing through both sides of the handle body, and a perforation 10 passing through the hand...

Embodiment 3

[0053] As attached to the manual Figure 5 As shown, a compound hip joint includes a femoral stem 1, a femoral neck 2, a spring 5 and a screw rod 6; The lower part is provided with a barb 3; the head of the femoral stem 1 is provided with an L-shaped through hole 4, and a mounting hole 7 communicating with the longitudinal hole in the L-shaped through hole 4; the lower part of the femoral neck 2 is inserted into the L-shaped through-hole 4. in the L-shaped through hole 4, and the barb 3 is hooked in the transverse hole in the L-shaped through hole 4; a spring 5 is arranged in the installation hole 7, and one end of the spring 5 is against the lower part of the femoral neck 2, and the other end is provided on the outside of the The screw rod 6 in the installation hole 7; the middle and lower parts of the handle body of the femoral handle 1 are respectively provided with a filling interlayer 9 that runs through both sides of the handle body, and a perforation 10 that runs throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com