Micro rails for large printers

A miniature technology for printers, applied in printing, transfer materials, power transmission devices, etc., can solve the problem that the moving distance of the sliding plate and the chute cannot be changed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

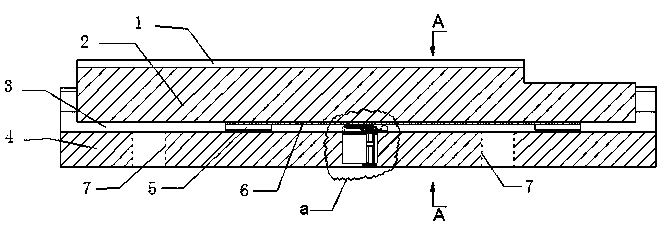

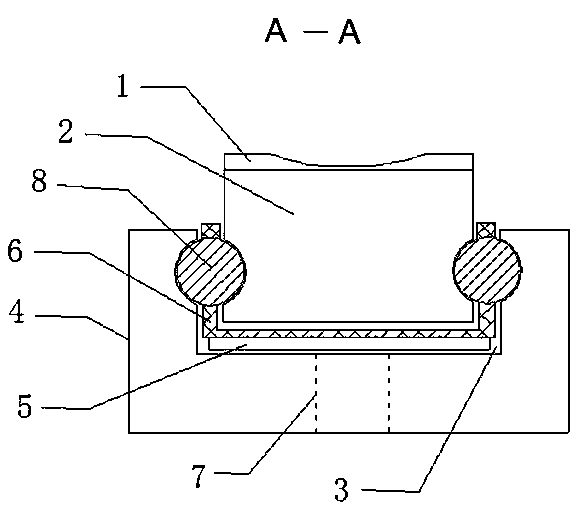

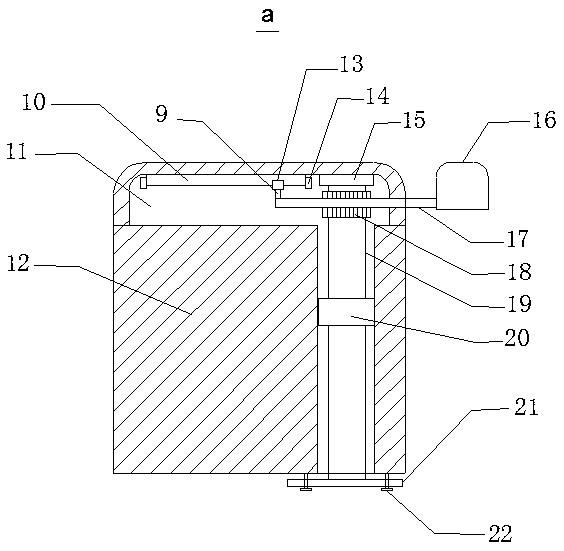

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] The miniature guide rail for a large printer of the present invention includes an arc plate 1, a sliding plate 2, a chute 3, a base 4, a bump 5, a plastic holder 6, a heat dissipation through hole 7, a steel ball 8, a pole 9, a slide rail 10, Groove 11, stake 12, slide block 13, limit block 14, flange bearing 15, insert block 16, rack 17, gear 18, rotating shaft 19, bearing, rotating plate 21 and screw 22, described base 4 A chute 3 is provided, and the inner bottom of the base 4 is provided with two heat-dissipating through-holes 7 , and the left and right side walls of the base 4 are respectively provided with first concave strips sunken inward, and the plastic cage 6 is arranged in the chute 3 , the left and right sides of the bottom of the plastic holder 6 are respectively equipped with protrusions 5, the protrusions 5 are located on the chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com