Centrifugal automatic control type variable exhaust valve structure

An exhaust valve, exhaust valve technology, applied in valve devices, engine components, machines/engines, etc., can solve problems such as instability, can not change the engine volume greatly, and achieve the goal of improving the compression ratio and engine performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

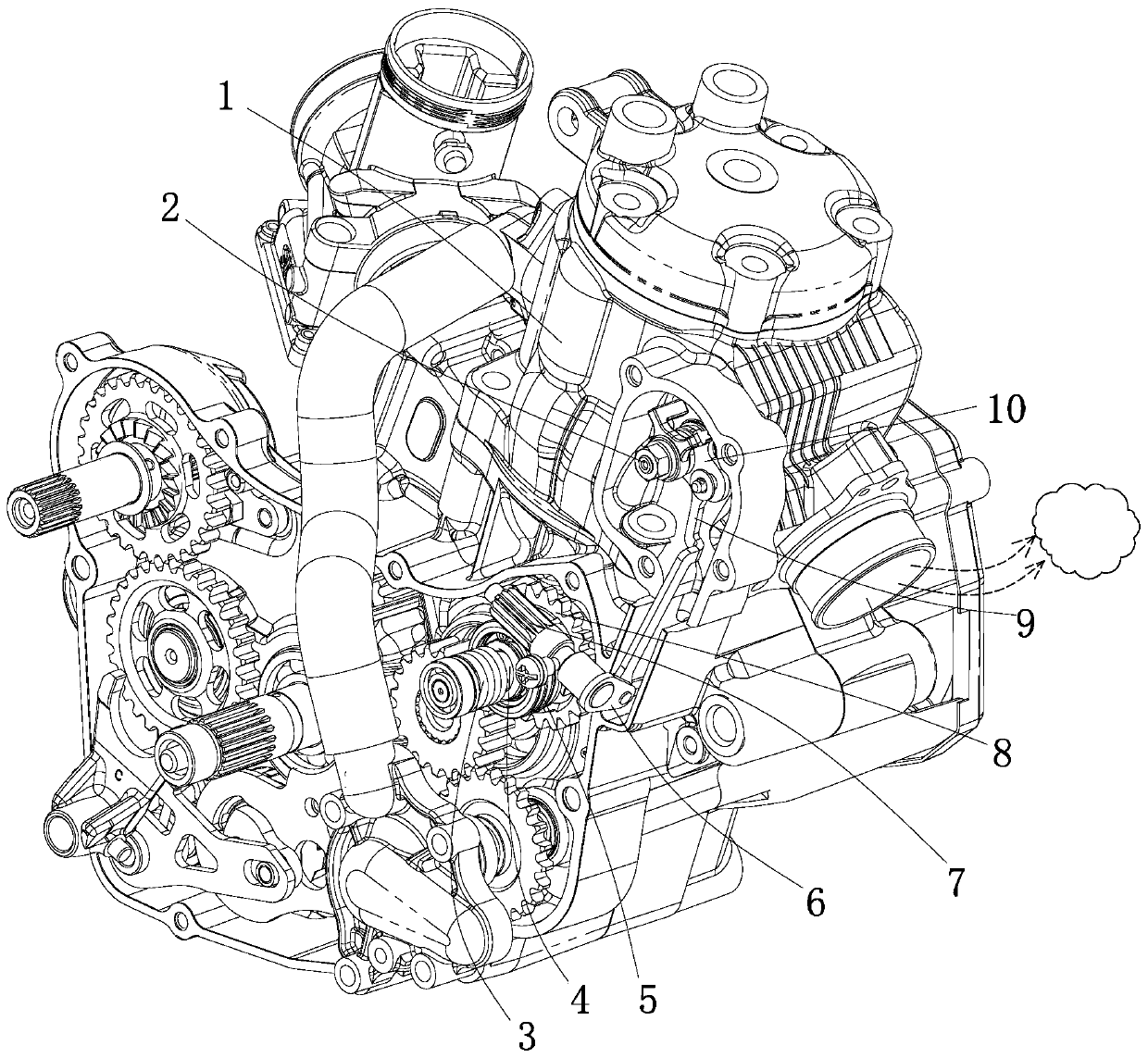

[0033] figure 1 As shown, the side of the engine cylinder 1 is provided with a chamber, and the engine crankshaft is connected with several linkages. The exhaust port of cylinder 1 is blocked by the exhaust valve, and the exhaust valve is connected on the control rod 2, and the diameter of the exhaust port can be changed by rotating the control rod 2.

[0034] The present invention includes a centrifugal adjuster arranged in the side chamber of the cylinder 1, and the centrifugal adjuster includes a centrifugal derivation part and a joint pushing part.

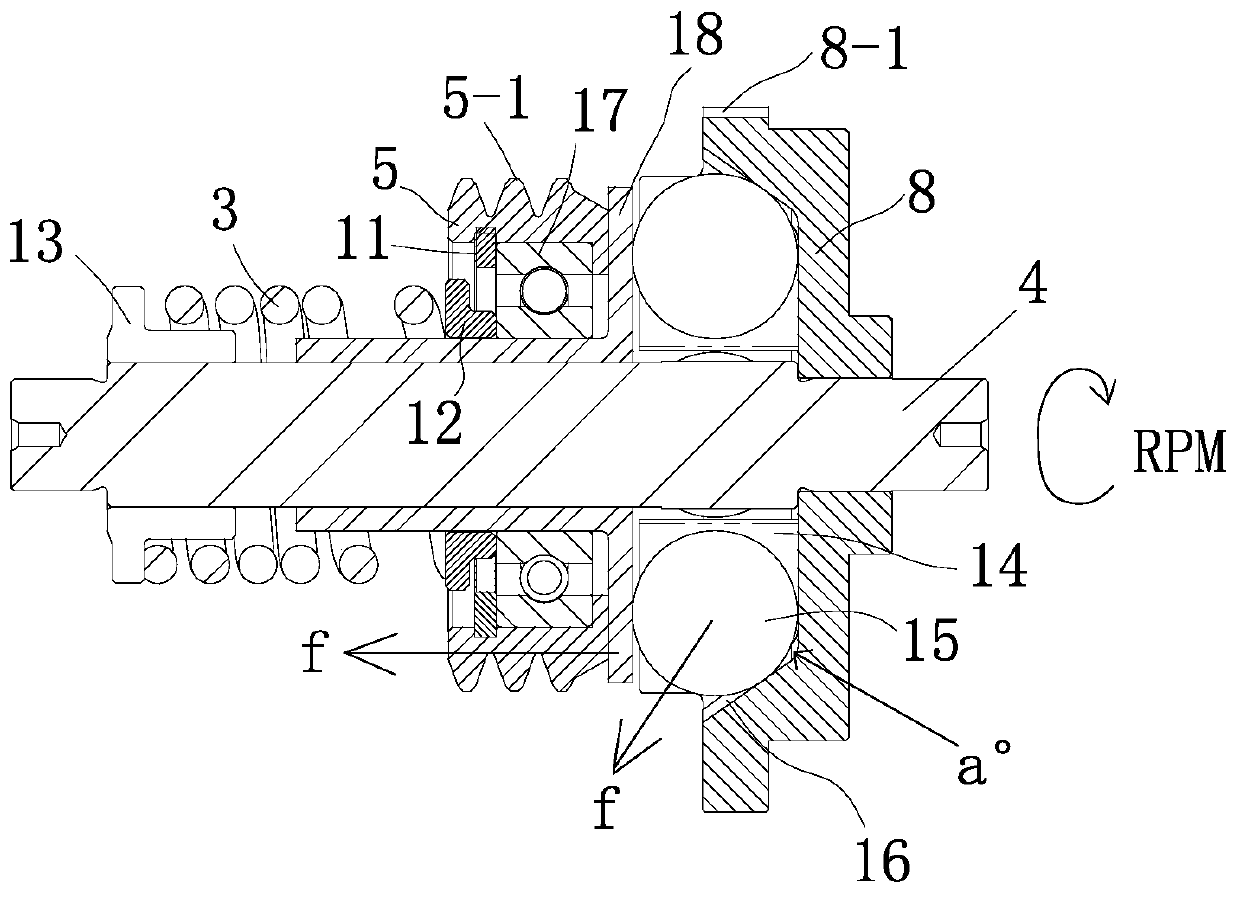

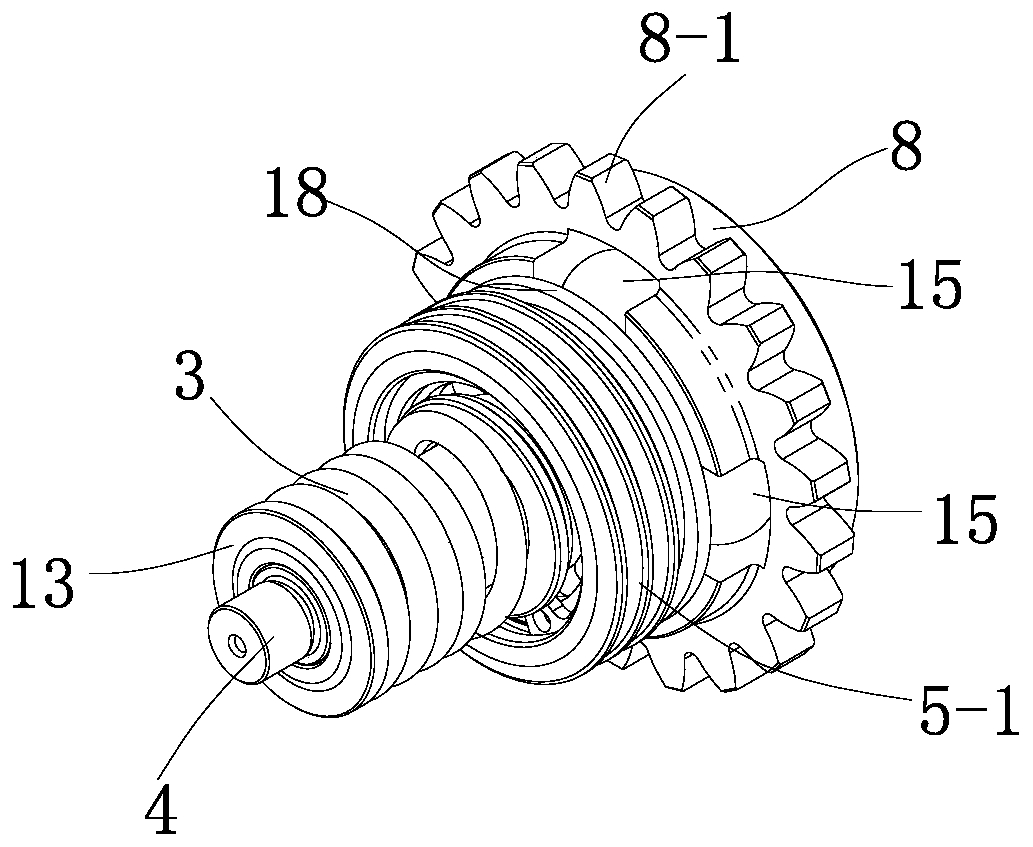

[0035] figure 2 , image 3 As shown, the centrifugal derivation part includes:

[0036] Central shaft 4, centrifugal disc 8, centrifugal steel ball 15, T word shaft sleeve 18, driving sleeve 5 and spring 3. The centrifugal disc 8 is sleeved on the central shaft 4, and the centrifugal disc 8 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com