A room temperature forming method of 2198 aluminum-lithium alloy sheet

A technology of aluminum-lithium alloy and plate, which is applied in the field of room temperature forming of 2198 aluminum-lithium alloy plate, can solve the problems of high cost and low efficiency, and achieve the effect of improving efficiency, high efficiency and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

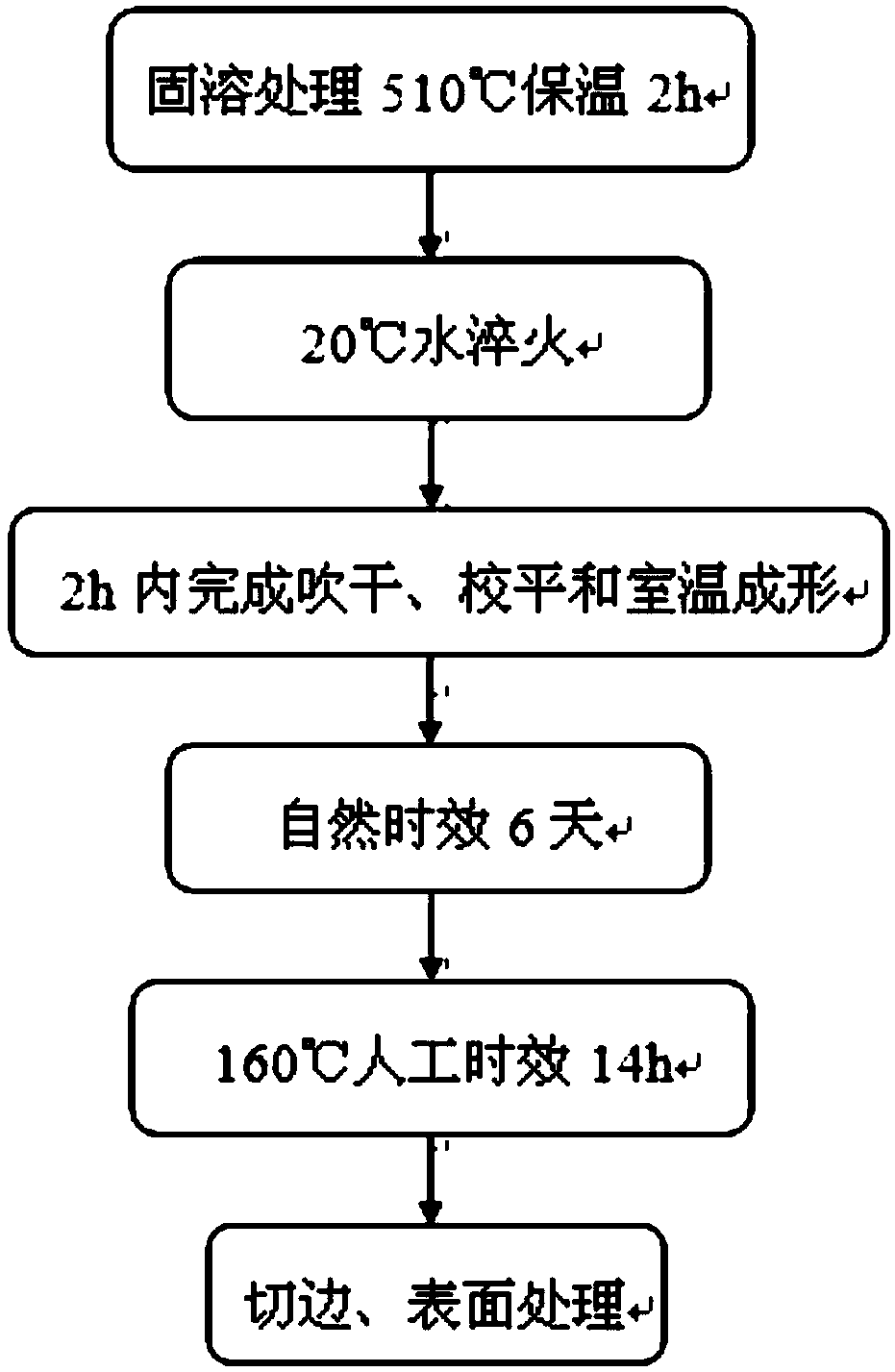

[0035] A room temperature forming method of 2198 aluminum-lithium alloy plate, its process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0036] Step 1, solid solution treatment

[0037] (1) Select a 2198 aluminum-lithium alloy plate with a thickness of 2.5mm, and the state is T8, and then cut the material according to the part drawing, check whether there are deep scratches and roughness on the surface, and clean the plate;

[0038] (2) Install the plate forming mold and lubricate the mold;

[0039] (3) Choose a conventional heat treatment furnace, raise the temperature of the furnace to 510°C and keep it warm for 1 hour. After the furnace temperature is stable, put the cleaned 2198 aluminum-lithium alloy plate into the heating furnace for heat preservation. The heat preservation time is 2 hours, and the solid solution is strictly controlled. Time prevents the degree of solid solution from being affected or the grains from growin...

Embodiment 2

[0052] A method for forming a 2198 aluminum-lithium alloy plate at room temperature, comprising the following steps:

[0053] Step 1, solid solution treatment

[0054] (1) Select a 2198 aluminum-lithium alloy plate with a thickness of 4mm and the state is T8, and then cut the material according to the part drawing, check whether there are deep scratches and roughness on the surface, and clean the plate;

[0055] (2) Install the plate forming mold and lubricate the mold;

[0056] (3) Choose a conventional heat treatment furnace, raise the furnace temperature to 500°C and keep it warm for 2 hours. After the furnace temperature is stable, put the cleaned 2198 aluminum-lithium alloy plate into the heating furnace for 1 hour, and strictly control the solid solution Time prevents the degree of solid solution from being affected or the grains from growing too much;

[0057] Step two, quenching treatment

[0058] Quickly take out the plate after solid solution from the furnace and ...

Embodiment 3

[0069] A method for forming a 2198 aluminum-lithium alloy plate at room temperature, comprising the following steps:

[0070] Step 1, solid solution treatment

[0071] (1) Select a 2198 aluminum-lithium alloy plate with a thickness of 0.5mm and the state is T8, and then cut the material according to the part drawing, check whether there are deep scratches and roughness on the surface, and clean the plate;

[0072] (2) Install the plate forming mold and lubricate the mold;

[0073] (3) Choose a conventional heat treatment furnace, raise the furnace temperature to 530°C and keep it warm for 1 hour. After the furnace temperature stabilizes, put the cleaned 2198 aluminum-lithium alloy plate into the heating furnace for 0.5 hours, and strictly control the solid The dissolution time prevents the degree of solid solution from being affected or the grains from growing excessively;

[0074] Step two, quenching treatment

[0075] Quickly take out the plate after solid solution from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com