A jet-type active drive device for vortex-induced vibration of standpipe

An active drive, vortex-induced vibration technology, applied in the direction of drill pipe, casing, pipe components, etc., can solve secondary disasters, huge economic losses, marine pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

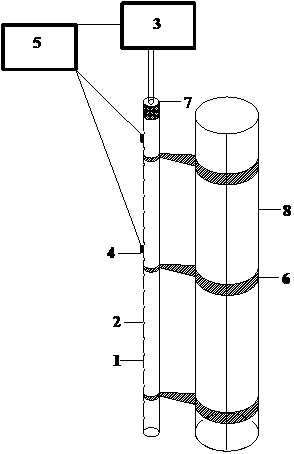

[0007] Such as figure 1 As shown, the perforated steel pipe 1 is connected to the standpipe 8 through the metal ferrule 6 arranged along the length, the perforated steel pipe 1 is in the direction of the incoming flow, the air injection holes 2 are all facing the direction of the incoming flow, and two groups are arranged along the upper part and the middle span of the standpipe The pressure sensor 4 is connected to the control computer 5, the control end of the high-pressure air pump 3 is connected to the control computer 5, and the output end is connected to the perforated steel pipe 1 through the booster valve 7. When there is ocean current or wave passing through the standpipe, the pressure sensor 4 transmits the signal to the control computer 5. When the pressure signal exceeds the set value, the control computer 5 automatically turns on the high-pressure air pump 3 and inputs the rated power according to the pressure signal value. Air pressure, the air pressure sprays hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com