Water-air mixing and atomizing assembly

A technology of atomizing components and water-air mixing, which is applied to spray devices, liquid spray devices, etc., and can solve problems such as poor ventilation, explosion, and reduced life expectancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

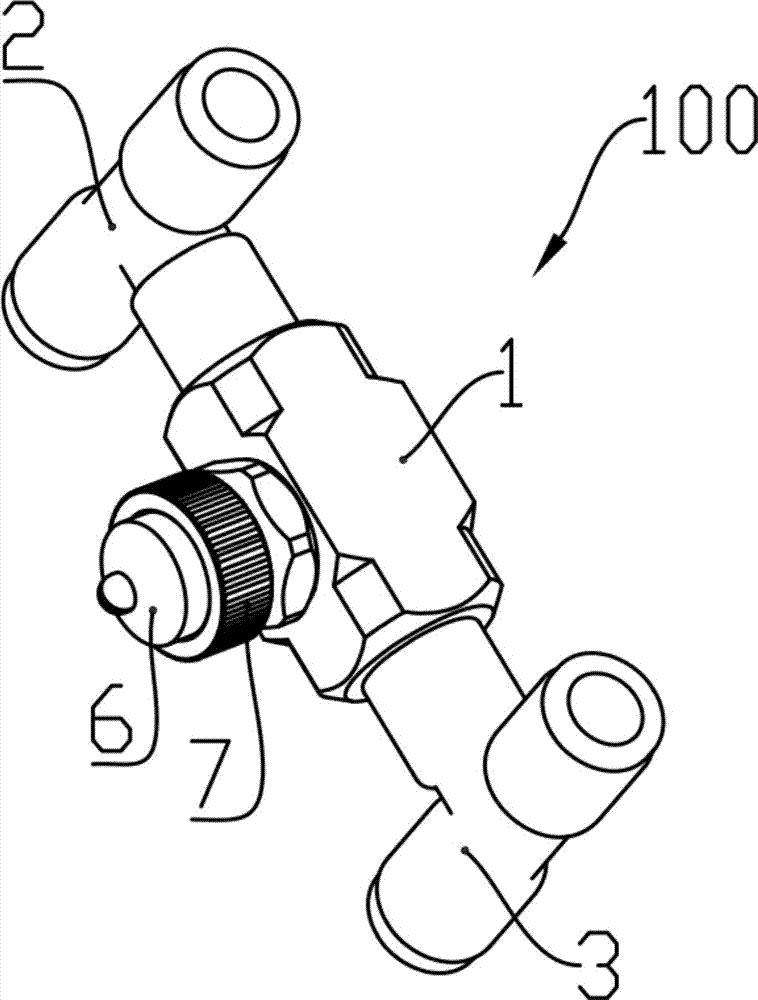

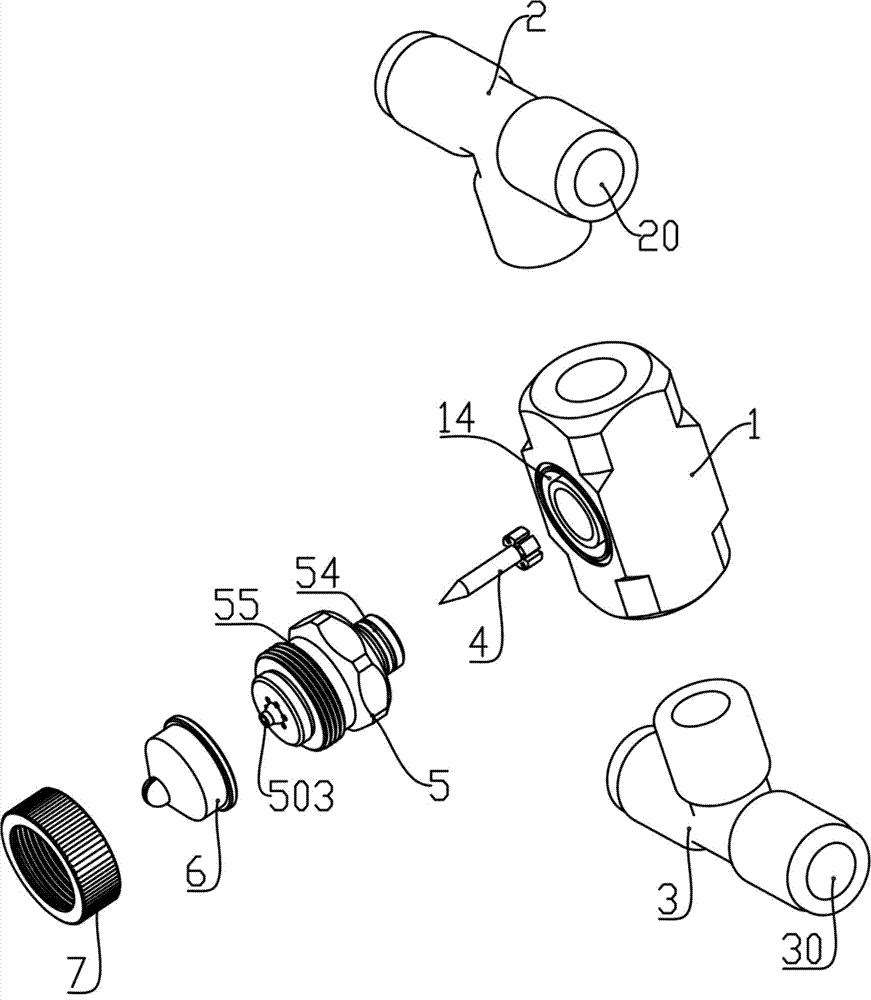

[0040] Combine below Figure 1 to Figure 10 The structure of the water-gas mixing atomization assembly applying the technical solution of the present invention is further described:

[0041] Such as figure 1 , figure 2 with Image 6 As shown, the water-air mixing atomization assembly 100 includes an atomization base 1 extending along the Y-axis direction, and the two ends of the atomization base 1 are respectively sealed and connected with T-shaped water connectors 2 and T-shaped air joints. Connector 3.

[0042] A water pipeline 20 arranged roughly along the X-axis direction and a first connecting water pipeline 21 arranged roughly along the Y-axis direction are arranged through the T-shaped water joint 2, and the water pipeline 20 and the first connecting water pipeline 21 are connected to each other. connected. The water pipeline 20 has a water inlet 201 and a water outlet 202 arranged in front and back. The liquid flowing into the water pipeline 20 through the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com