Electrolysis system with descaling device, and descaling method

An electrolysis system and electrolysis device technology, applied in the field of cathode automatic cleaning electrolysis device, can solve problems such as affecting the electrolysis efficiency, affecting the life of the anode, affecting the life of the electrode, etc., so as to reduce the cleaning waste liquid treatment device, simplify the pipeline layout, and eliminate the two problems. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in detail.

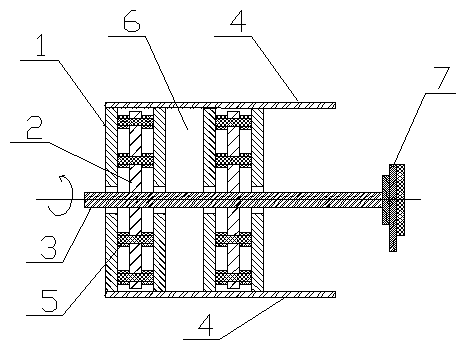

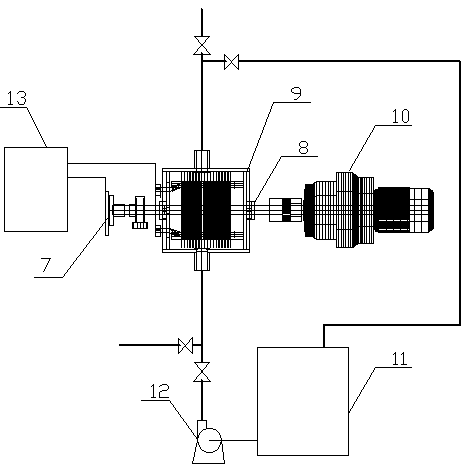

[0025] Such as figure 1 , figure 2 , image 3 Shown is an electrolysis system with a descaling device, which mainly includes an electrolysis device, a cleaning ball storage tank 11, a transfer pump 12, and a power supply 13; the liquid inlet of the electrolysis device is connected to the outlet of the transfer pump 12 through a pipeline, The liquid outlet of the electrolysis device is connected to the cleaning ball storage tank 11 through a pipeline, and the liquid outlet of the cleaning ball storage tank 11 is connected to the inlet of the delivery pump 12 through a pipeline;

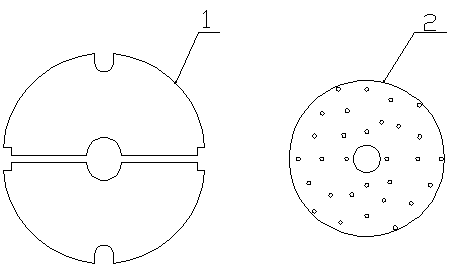

[0026] Described electrolysis device mainly comprises tank body 9, rotating device 10, anode power receiving device 7, shaft seal 8; There are cathode disc 1, anode disc 2, anode conducting rod 3, cathode conducting rod 4 in the described tank body; The outer edge of the cathode circular plate 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com