Automatic dust removal device and plate dividing machine

A technology of automatic removal and dust removal, which is applied in the direction of cleaning methods, cleaning methods and utensils, and metal processing using gas flow, which can solve the problems of abnormal function of PCBA circuit boards and no further automatic removal of residual dust, so as to avoid abnormal functions, Automate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

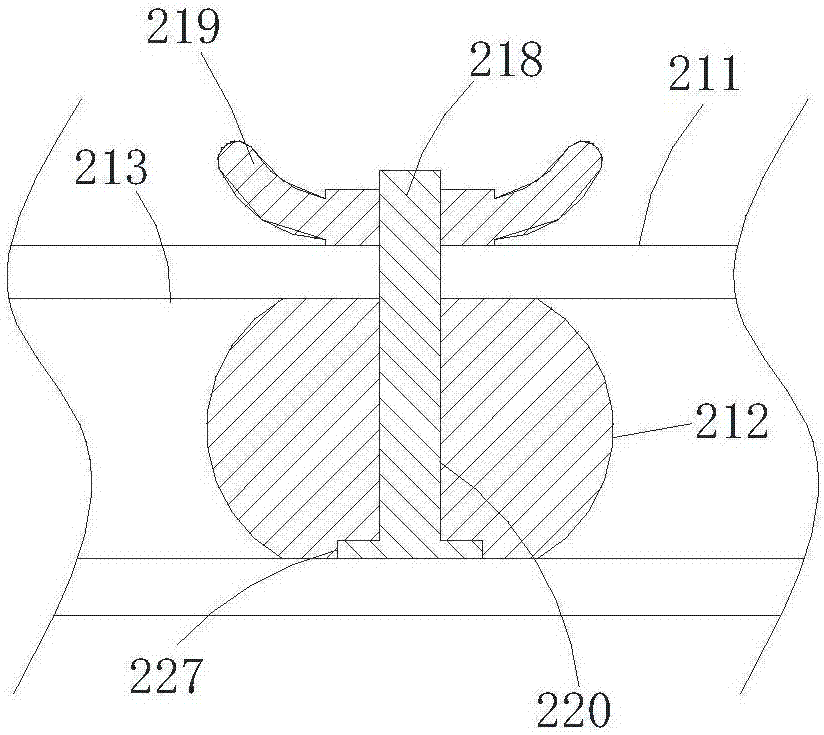

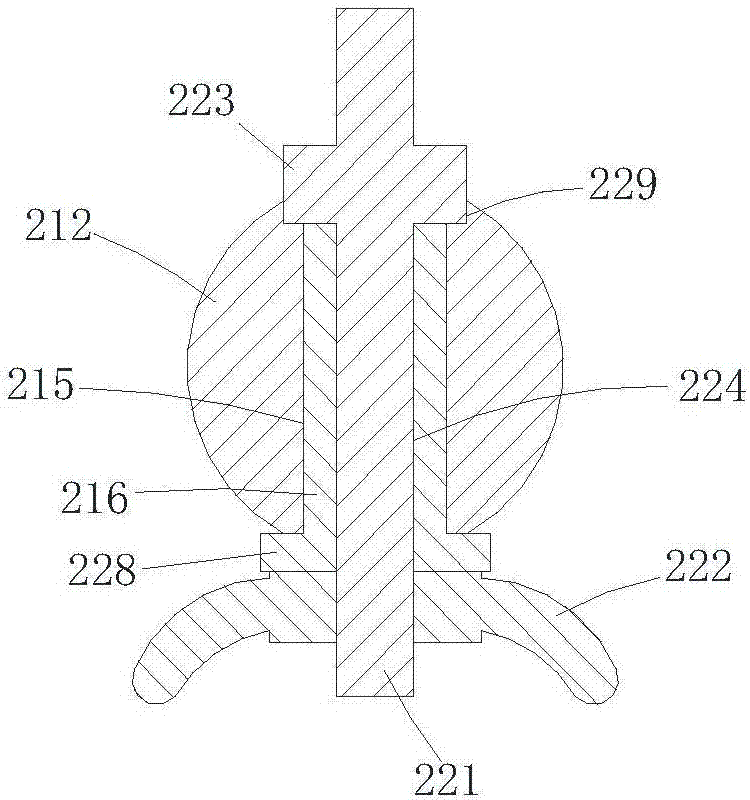

[0035] Such as Figure 1-2As shown, between the slider 216 and the second pole 212, the slider 216 after the adjusted position is limited and fixed by the second adjustment assembly. As an embodiment of the present invention, the second adjustment assembly includes The second adjusting screw 221 and the second nut 222 threadedly connected with the second adjusting screw 221, one end of the second adjusting screw 221 is provided with a stop portion 223 with a diameter greater than the diameter of the second adjusting screw 221, on the slider 216 is provided with a second screw hole 224, the second adjusting screw 221 extends from the upper end of the second pole 212 through the second screw hole 224 from the lower end of the second pole 212, and passes through the second nut 222 Threaded connection, the limiting portion 223 abuts against the lower end of the second pole 212 , thereby preventing the fixed slider 216 from coming out of the third guide hole 215 .

[0036] One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com