A clamping device and clamping method for surface processing of high-steep conformal headgear

A surface processing and clamping device technology, applied in the direction of clamping devices, positioning devices, metal processing equipment, etc., can solve problems such as difficult disassembly, achieve safe disassembly, avoid damage, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

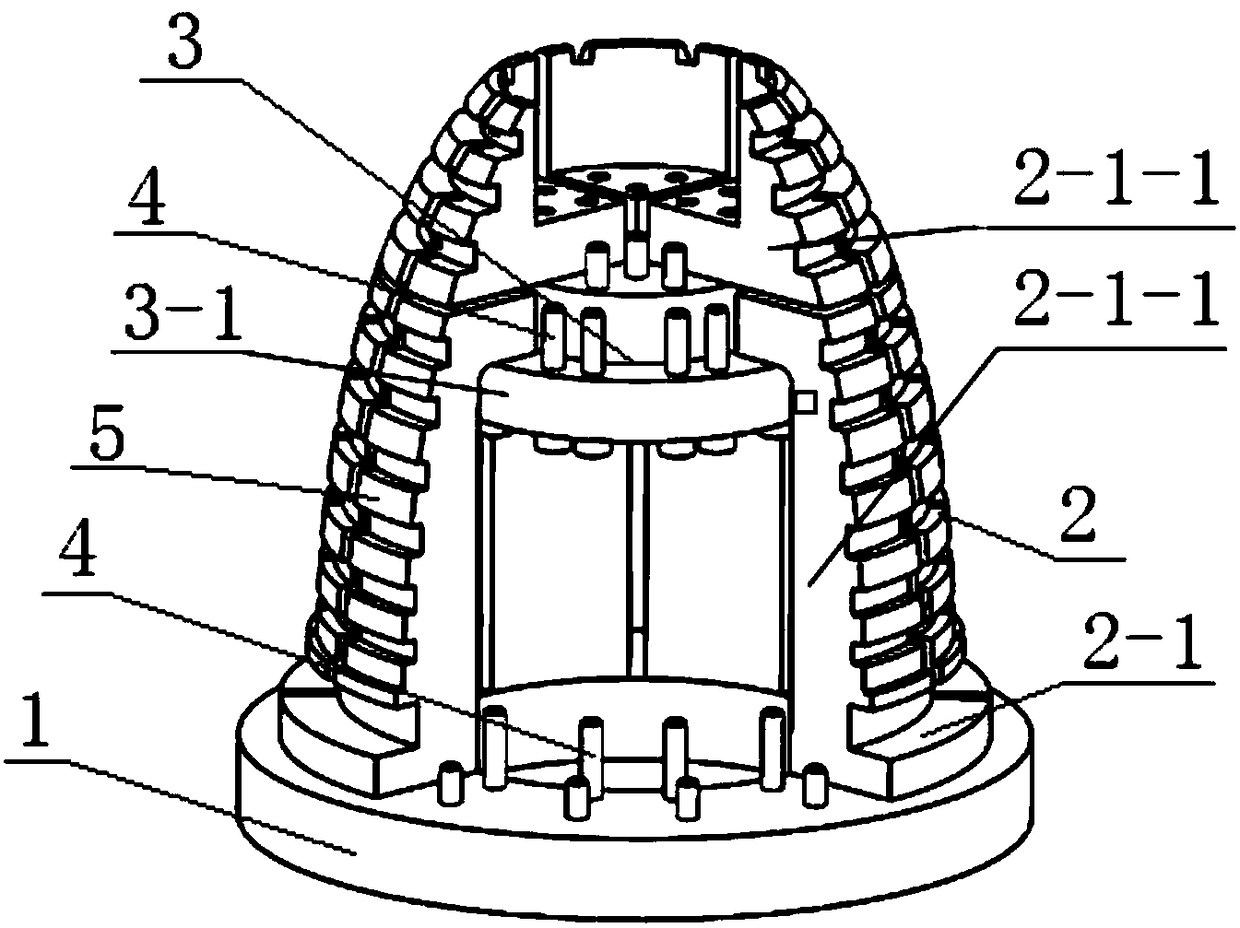

[0016] Specific implementation mode one: combine figure 1 This embodiment is described. A clamping device for high-steep conformal hood surface processing described in this embodiment includes a clamp base 1, a positioning assembly 2 and a fixing mechanism 3, and the positioning assembly 2 is fixed on the bottom of the clamp base 1. On the upper end face, the outer wall of the positioning assembly 2 is evenly arranged with a plurality of curved bosses 5 along the axial direction, each curved boss 5 is arranged along the outer circumferential direction, and the curve equation formed by the outer surface of the curved boss 5 is the same The curve equations of the inner surface of the hood are the same, and the positioning assembly 2 includes a plurality of clamp bases 2-1, and the multiple clamp bases 2-1 are evenly distributed along the circumferential direction to form a conical positioning assembly 2, and two adjacent clamp bases 2-1 There is a gap between 1, and a plurality ...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 Describe this embodiment, the jig base 2-1 in this embodiment includes a plurality of base blocks 2-1-1, the base blocks 2-1-1 are arranged in sequence from bottom to top, and two adjacent base blocks 2-1 There is a gap between -1, and the curved surface boss 5 is arranged on the outer surface of the base block 2-1-1. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0019] Such a design further optimizes the size and structure of the positioning component 2 with the goal of reducing the mass on the premise of ensuring the rigidity of the positioning component 2, so as to further reduce the influence of the material expansion of the positioning component 2 due to heating and temperature rise during disassembly.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the fixing mechanism 3 in this embodiment includes a plurality of fixed discs 3-1, and the plurality of fixed discs 3-1 are arranged horizontally from top to bottom, and the outer diameter of the fixed discs 3-1 is from top to bottom. Incrementing from bottom to bottom, the inner sides of the plurality of base blocks 2-1-1 are fixedly connected to the fixed discs 3-1 respectively. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

[0021] Such a design realizes effective positioning between multiple base blocks 2-1-1, making it form a complete positioning assembly 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com