Auxiliary jacking device for tire crane

A jacking device and tire crane technology, applied in the direction of transportation and packaging, load suspension components, trolley cranes, etc., can solve problems such as tire damage, tire failure, bulging, etc., to prolong service life, reduce impact, and tire wear Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

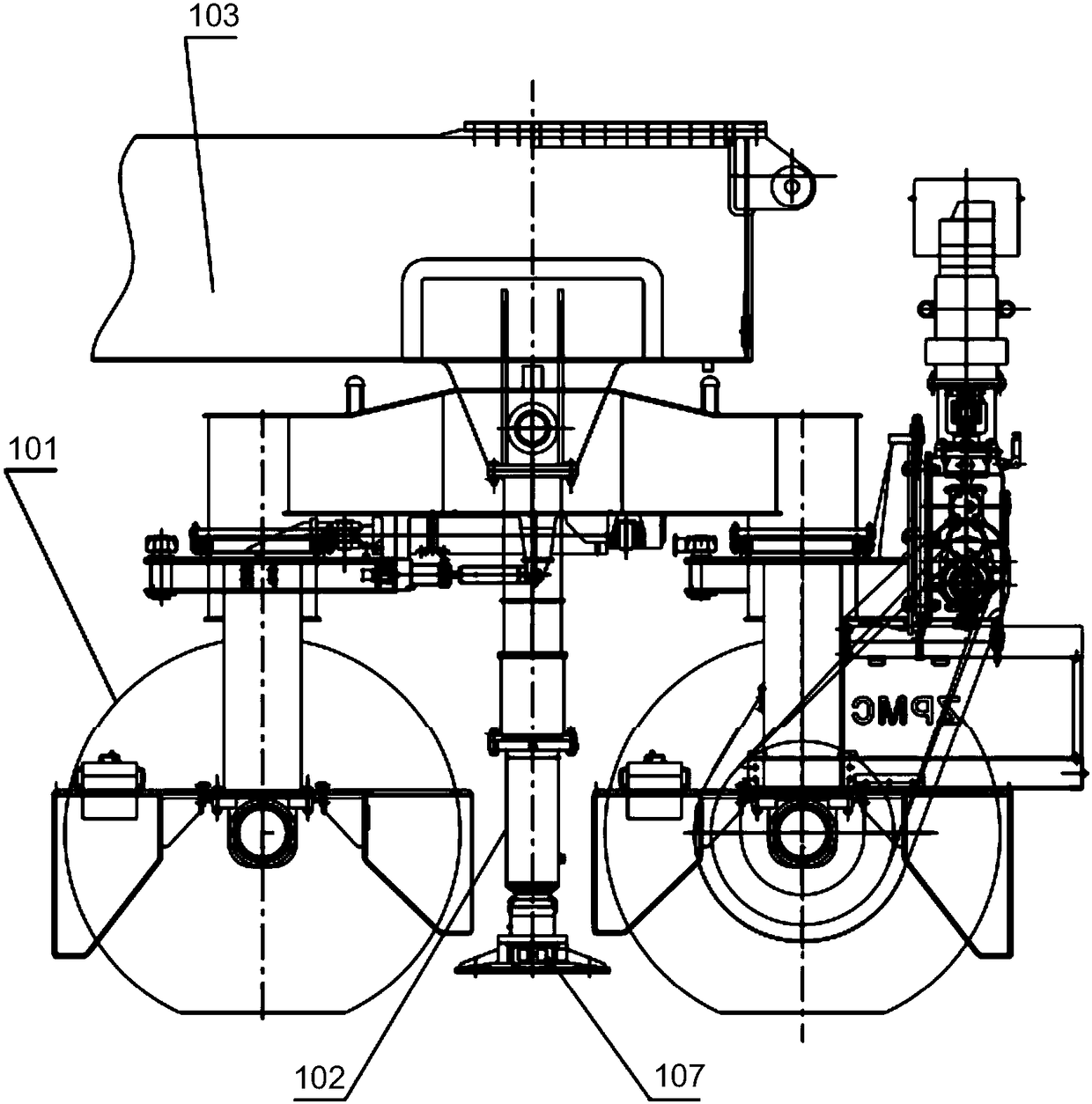

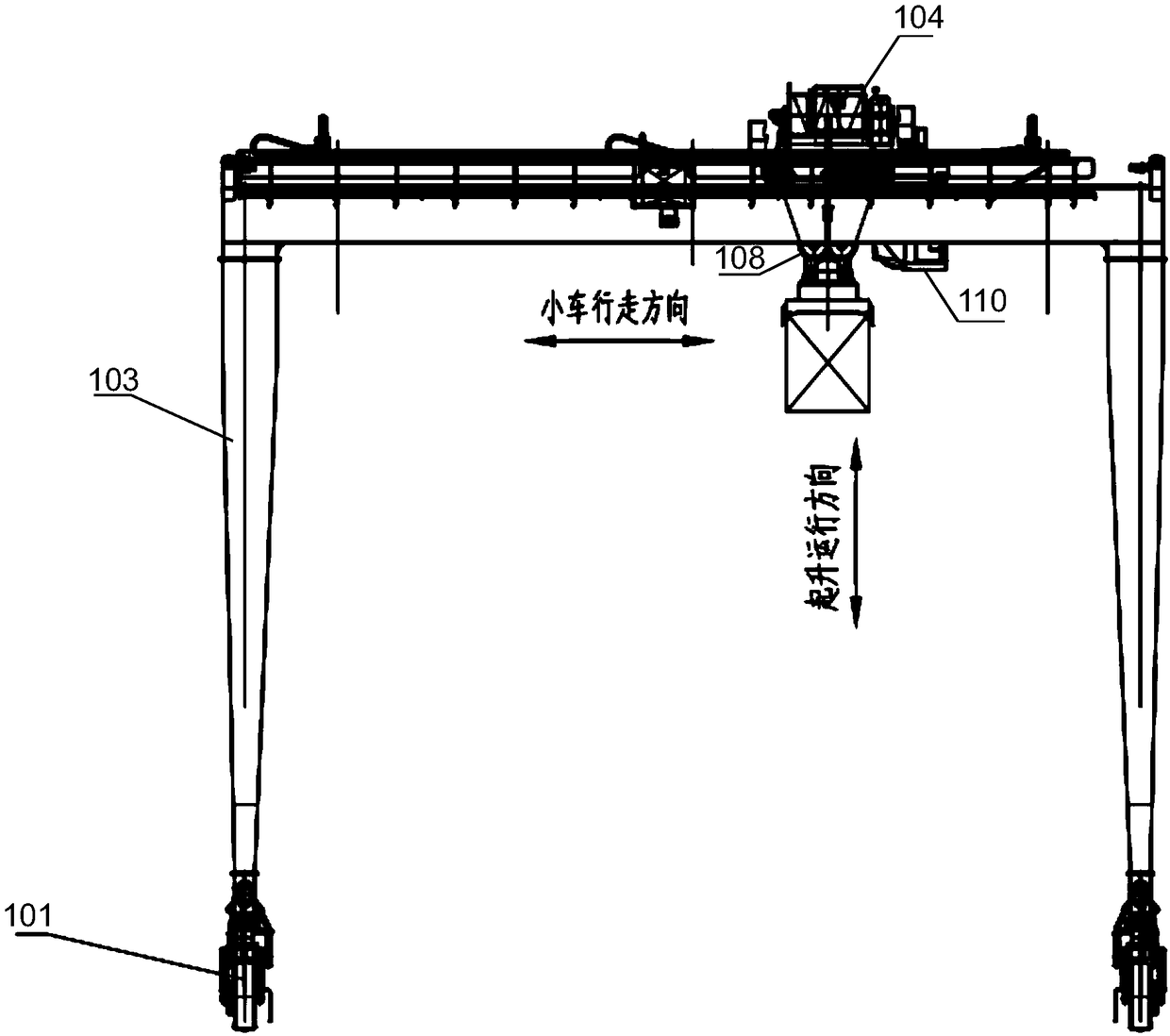

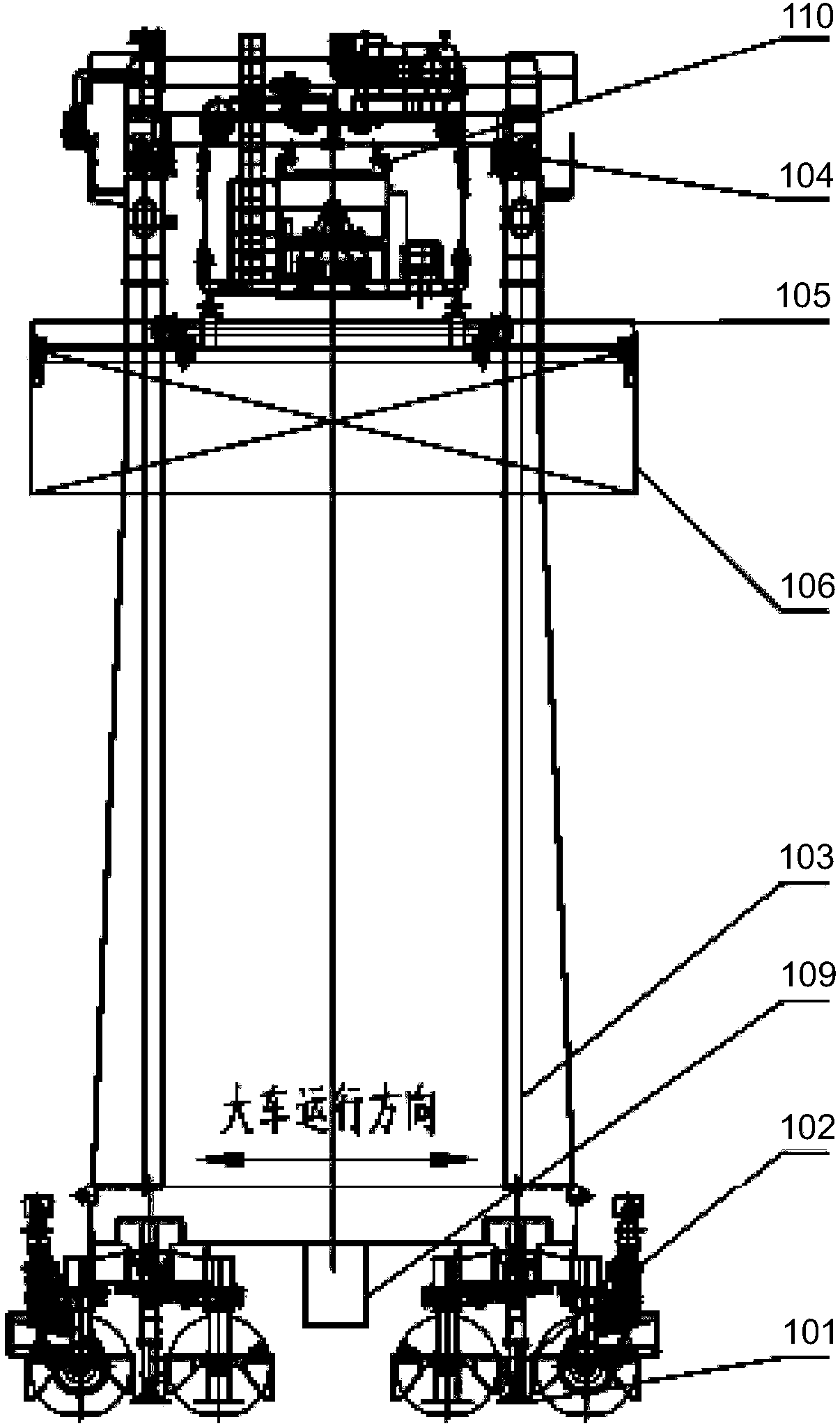

[0020] First reference Figure 2a , Figure 2b with Figure 2c As shown, Figure 2a , Figure 2b with Figure 2c The structure diagram of the tire crane applying the auxiliary lifting device of the tire crane of the present invention is disclosed, wherein Figure 2a Is the side structure diagram, Figure 2b Is the front structure diagram, Figure 2c It is a top view structure diagram. The auxiliary lifting device of the tire crane of the present invention can be applied to any existing tire crane. The tire crane includes the following structures: a frame 103, a cart mechanism 101, a cart mechanism 104, a lifting mechanism 108, and an operating room 110. The frame 103 includes a column and a main beam. The cart mechanism 101 is installed at the bottom of the column of the frame 103, and the cart mechanism 101 is equipped with tires. The trolley mechanism 104 is installed on the main beam of the frame 103, and the running direction of the trolley mechanism 104 is perpendicular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com