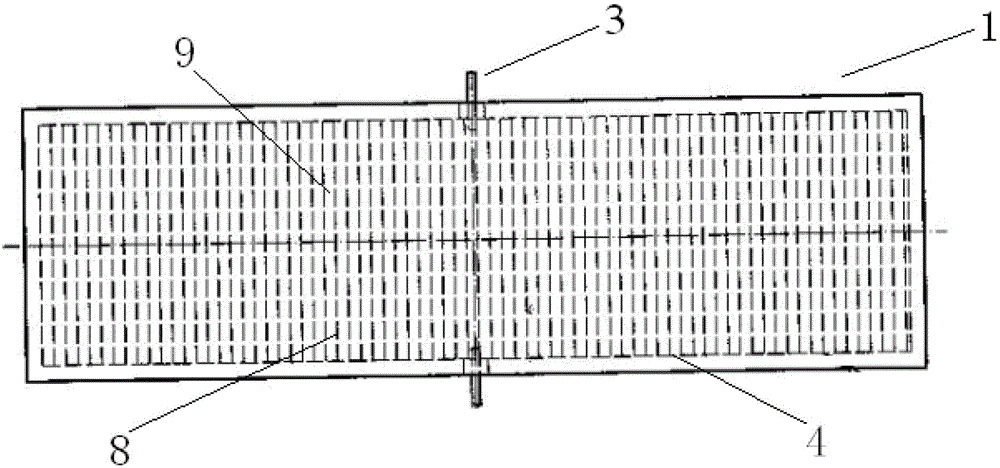

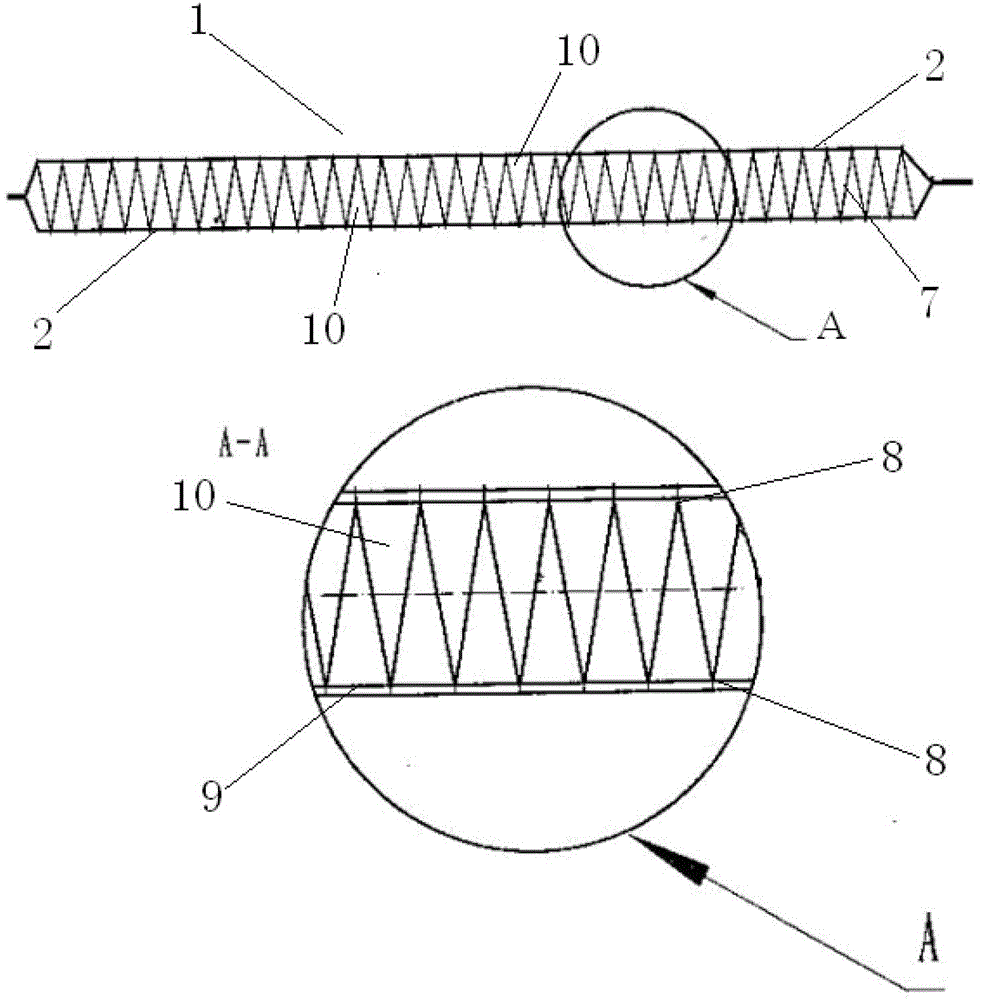

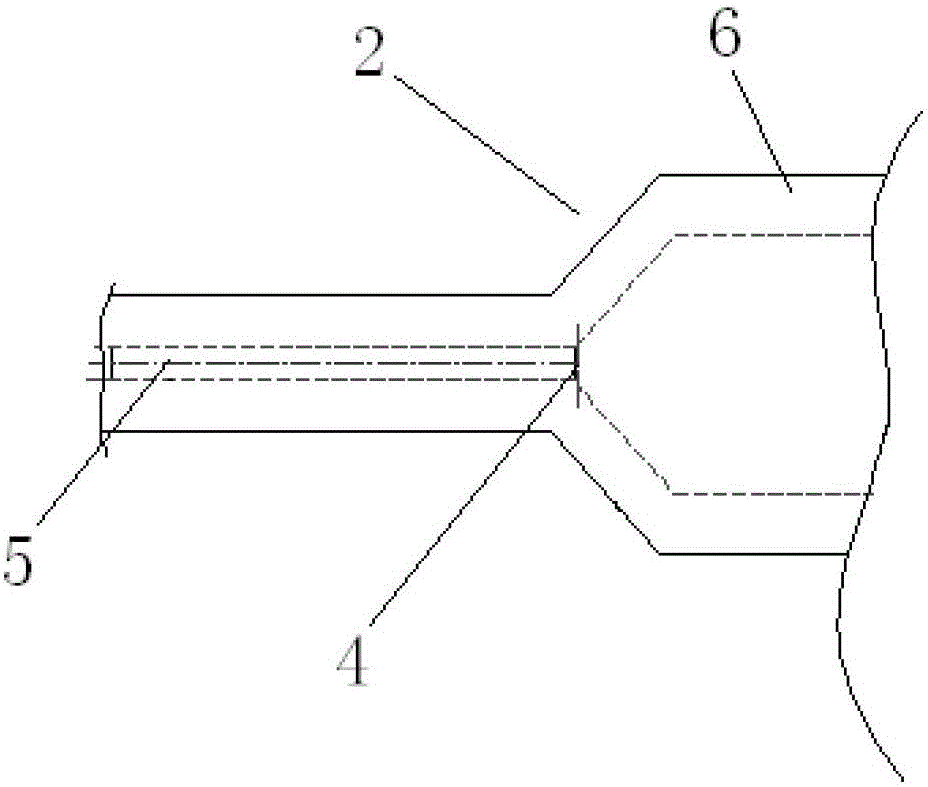

Pressurized gasbag of pipeline repair reinforcing layer as well as preparation method and application thereof

A technology for pipeline repair and reinforcement layer, which is applied in the field of pipeline repair and reinforcement layer pressurized airbag and its preparation and application, and can solve problems such as safe operation and integrity management of in-service pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] The implementation process and beneficial effects of the present invention are described in detail below through specific examples, aiming to help readers better understand the essence and characteristics of the present invention, and not as a limitation to the scope of implementation of this case.

[0104] Glue preparation

[0105] Prepare the glue solution according to the ratio of dry glue: solvent (ethyl ester) = 1:4, and add KH550 silane coupling agent at 5 g / kg when used. Using neoprene as the rubber material for attachment, its formula is as follows:

[0106] Neoprene 121 (Shanxi Datong Rubber Factory) 100 parts

[0108] Magnesium oxide 4 parts

[0109] 2 parts stearic acid

[0110] General purpose carbon black 25 parts

[0111] Barium sulfate 10 parts

[0112]Transformer oil 10 parts

[0113] 15 parts o-dibutyl ester

[0114] NA-22 0.5 parts

[0115] Blastocyst sewing

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com