Damping spring of washing and dewatering machine

A technology of shock-absorbing springs and wash-extractors, which can be applied to other washing machines, washing devices, textiles, and papermaking. It can solve the problems of easy damage, unreasonable structural design, and inability to apply to large-scale industrial production, so as to achieve reasonable integration of resources and overall well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

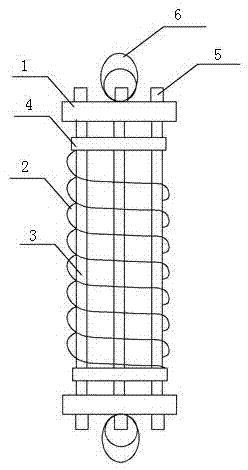

[0013] Such as figure 1 As shown, a shock-absorbing spring of a washing machine includes a guide rail device, a slide block 1 disposed at both ends of the guide rail device and a spring 2 wound around the guide rail device, and the guide rail device is a plurality of guide rail posts 3, and the two ends of the guide rail post 3 A limit block 4 is provided.

[0014] There are at least four rail columns 3 . The diameter of rail post 3 is 1-3cm. The section diameter of spring 2 is 1-3cm. The height of limit block 4 is 2-3cm. The rail column 3 passes through the slider 1 and is connected with a connecting ring 5 . Positioning rings 6 are provided at both ends of the spring 2 .

[0015] The above content is an example and description of the present invention, but it does not mean that the advantages that the present invention can obtain are limited by ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap