Live-line working device for defect detection of composite insulator of power transmission line

A composite insulator and defect detection technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as difficulty in electrification, high position of composite insulators, inaccurate measurement of insulators, etc., to achieve improved stability and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

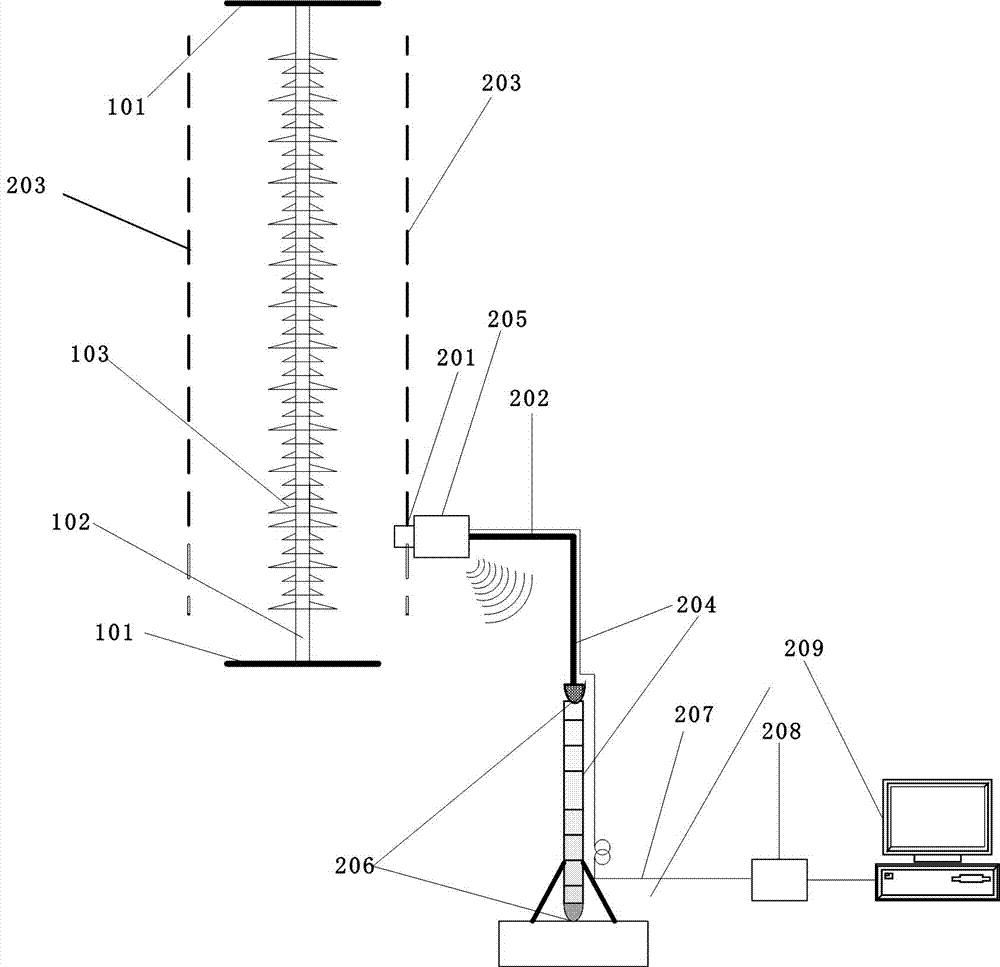

[0021] Such as figure 1 As shown, a live working device for detecting defects of composite insulators on transmission lines includes: a photoelectric electric field sensor 201 , a sliding track 203 , a lifting mechanism 204 , a polarized light source module 205 , and a ground acquisition and calculation module 209 . The sliding track 203 is at a certain distance from the outer surface of the large insulator shed 103, and the photoelectric electric field sensor 201 slides along the sliding track 203 from the high voltage end to the low voltage end at a constant speed. connect. The laser source in the polarization light source module 205 is connected to the photoelectric electric field sensor 201 through the polarizer and the polarization maintaining optical fiber 20, and the polarized light is modulated in the photoelectric electric field sensor 201 and transmitted to the next-stage polarization maintaining optical fiber, and then enters the photoelectric conversion module 208;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com