Splicing type movable safety rail

A safety fence and splicing technology, which is applied in the direction of fences, building types, buildings, etc., can solve the problems of time-consuming and labor-intensive disassembly and use, inconvenient transfer, narrow application area, etc., and achieve light weight, convenient and quick use, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

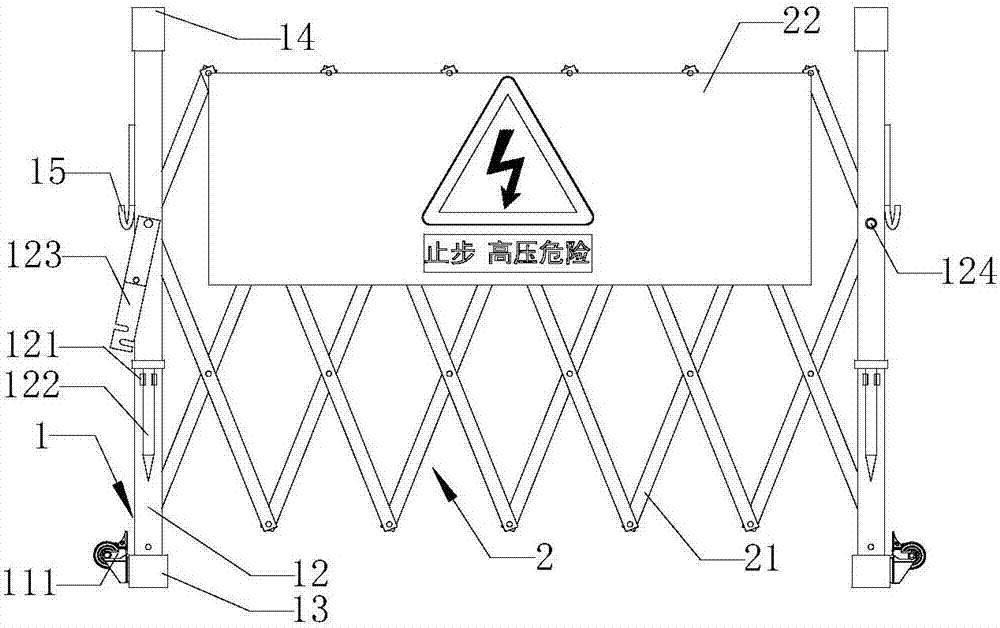

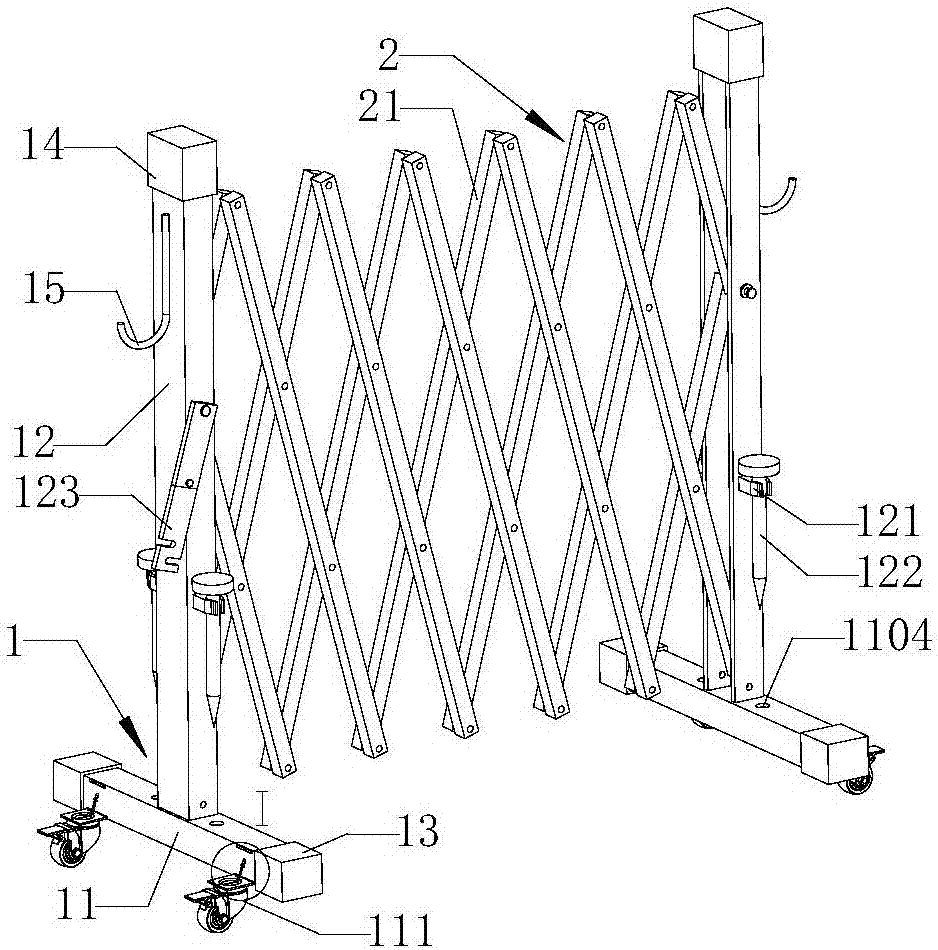

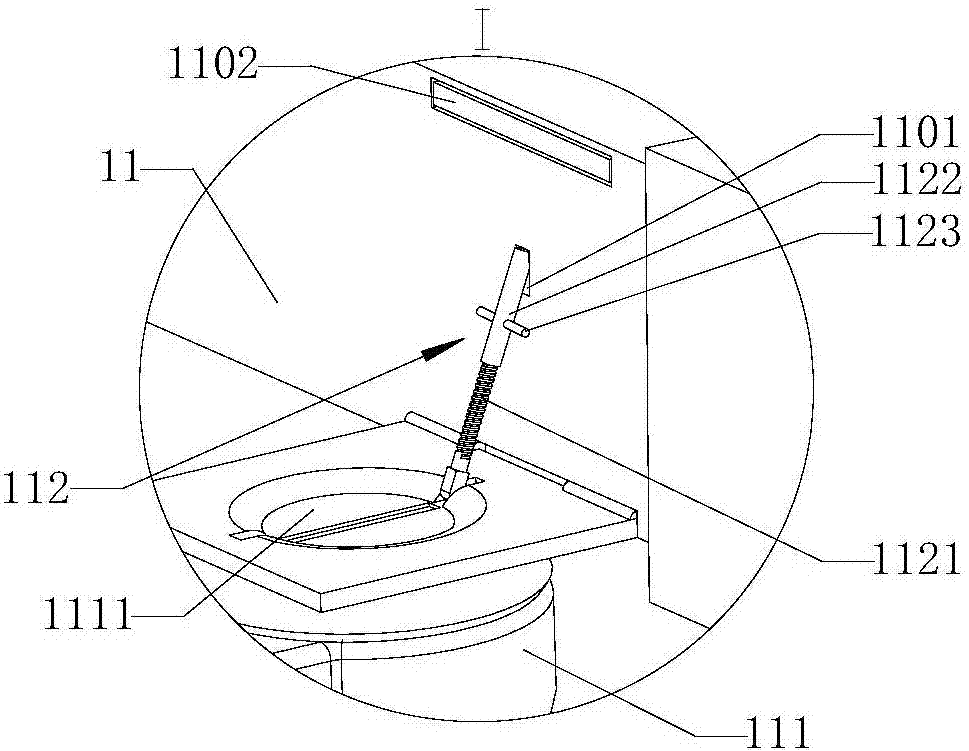

[0035] Such as Figure 1-7 As shown, a spliced movable safety fence includes two uprights 1 and a telescopic fence 2 connected between the two uprights 1. The telescopic fence 2 is composed of a plurality of cross-hinged railings 21. The upright 1 includes a base 11 and The column shaft 12 vertically fixed on the base 11; two casters 111 are hinged on the lower outer edge of each base 11, and the two casters 111 are symmetrically distributed at the two ends of the base 11, and the top of each caster 111 is An accommodating groove 1111 is provided, and a telescopic support rod assembly 112 is arranged in the accommodating groove 1111, and one end of the supporting rod assembly 112 is hinged in the accommodating groove 1111, and a supporting groove 1101 is provided on the outer surface of the base 11. After 111 is unfolded in place, the other end of the support rod assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com