A device for evenly spreading talc powder for shoelaces

A material spreading device and talc powder technology, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of talcum powder falling on the ground, troublesome cleaning personnel, waste of talcum powder, etc., and achieve cleanliness , Saving talcum powder, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

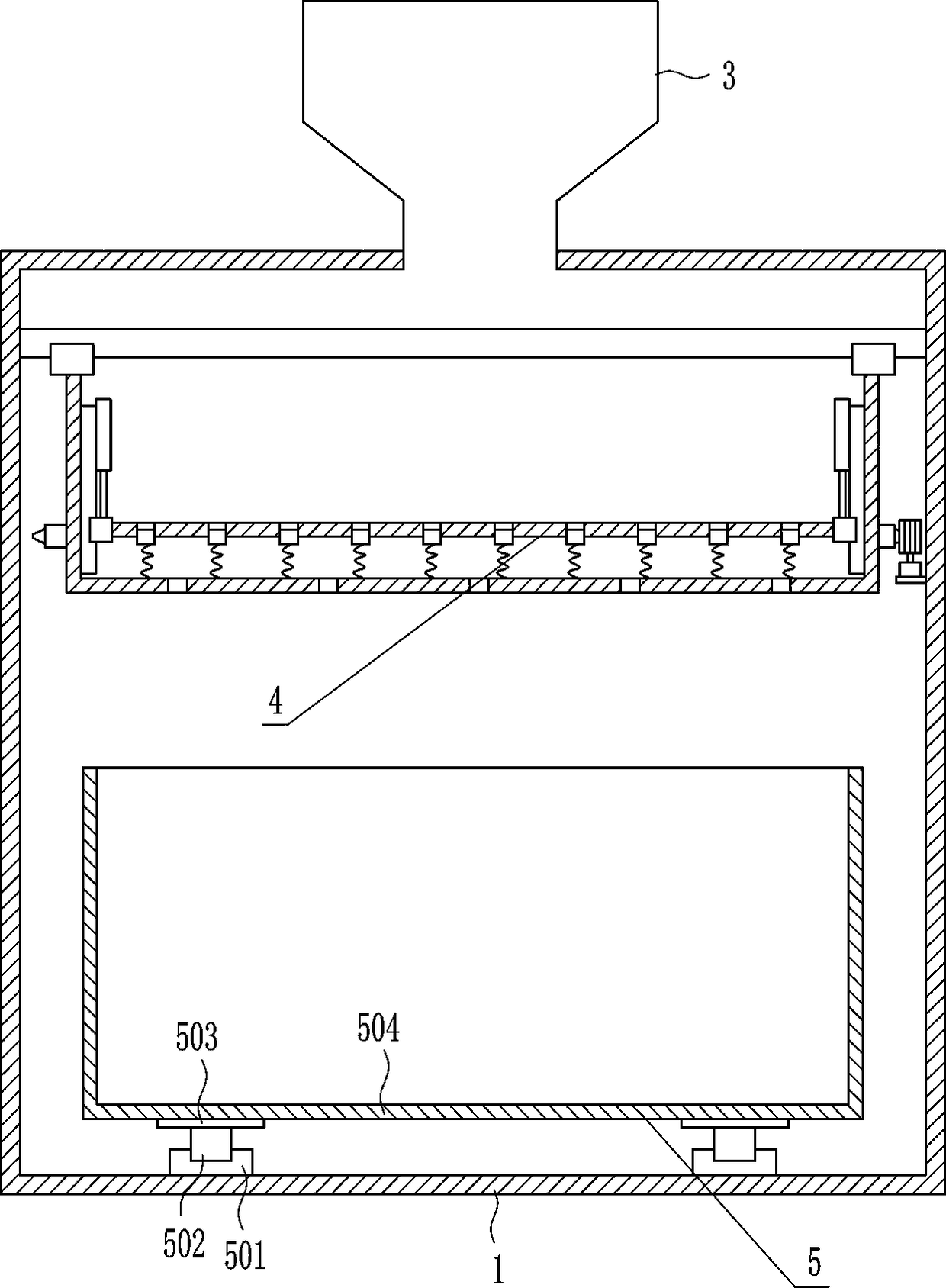

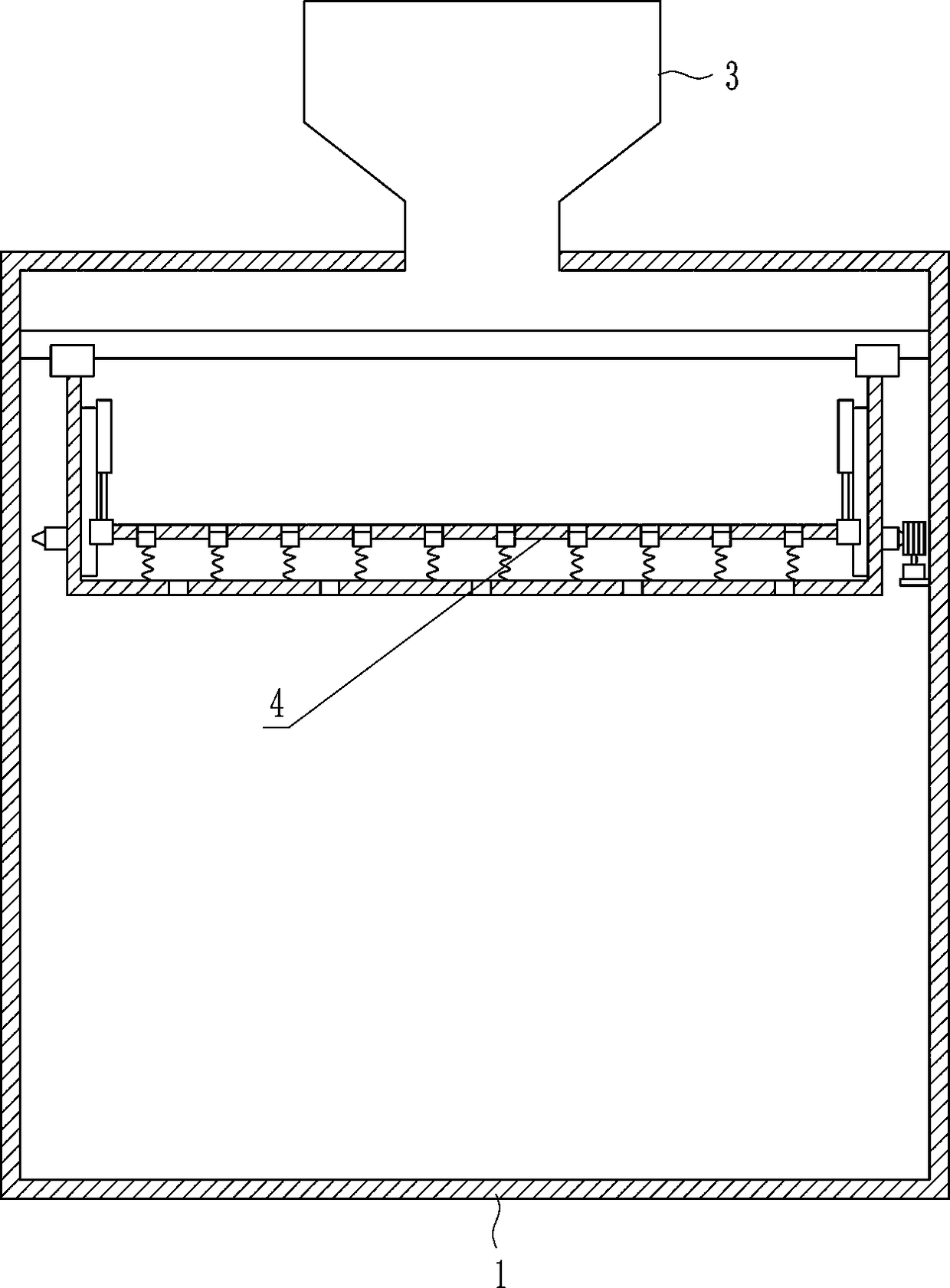

[0038] A kind of talc powder evenly spreading device for tying shoelaces, such as Figure 1-9 As shown, it includes a box body 1, a lower hopper 3 and a lower material device 4, the middle part of the front side of the box body 1 has an opening 2, the top of the box body 1 is equipped with a lower hopper 3, and the upper part of the box body 1 is provided with a lower Material device 4.

Embodiment 2

[0040] A kind of talc powder evenly spreading device for tying shoelaces, such as Figure 1-9 As shown, it includes a box body 1, a lower hopper 3 and a lower material device 4, the middle part of the front side of the box body 1 has an opening 2, the top of the box body 1 is equipped with a lower hopper 3, and the upper part of the box body 1 is provided with a lower Material device 4.

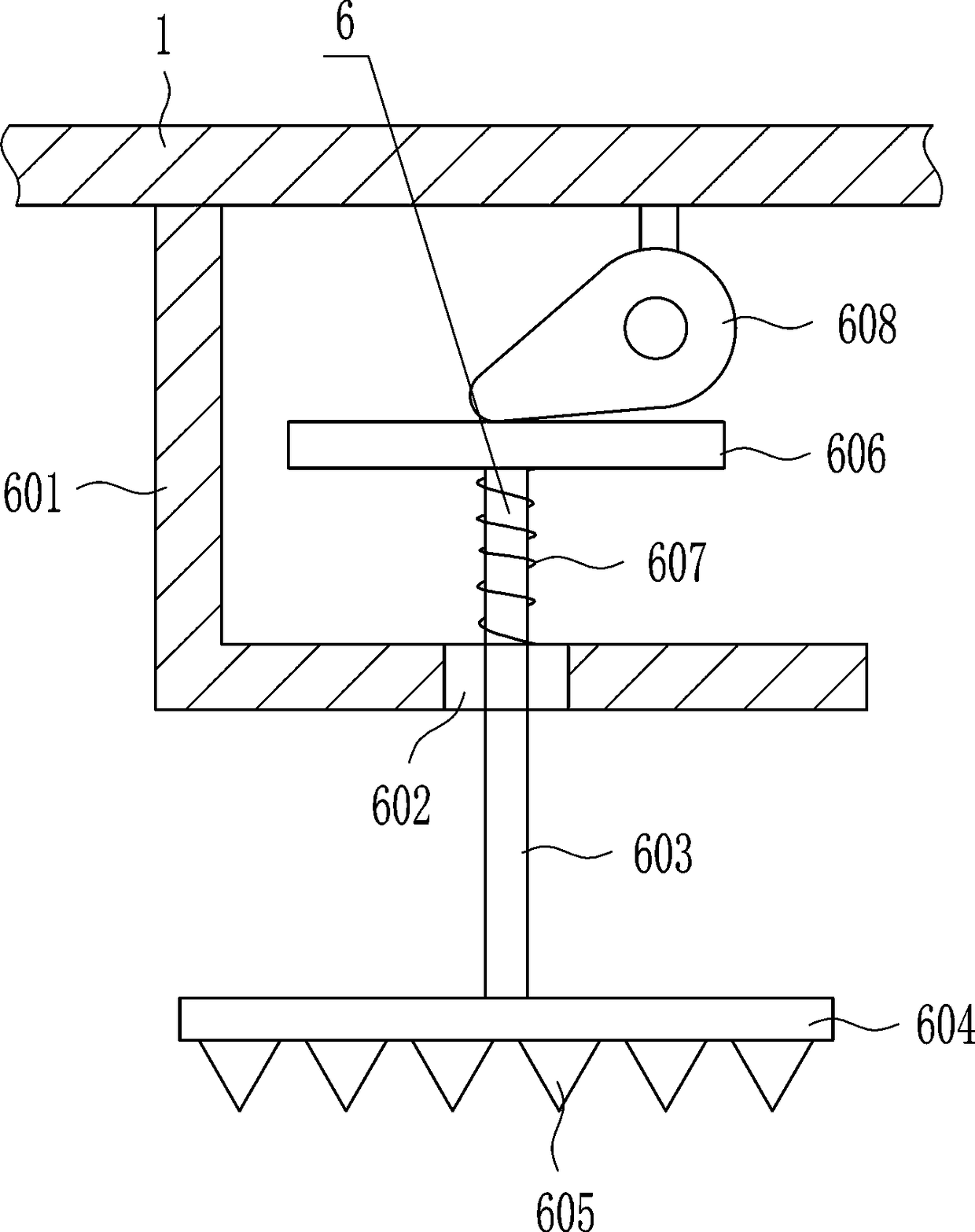

[0041] The blanking device 4 includes an annular slide rail 401, a first slide block 402, a frame body 403, a ring gear 405, a first slide rail 406, a second slide block 407, a telescopic device 408, a baffle plate 409, a first spring 411, Blocking block 412, connecting block 413, first motor 414 and gear 415, the left side of ring slide rail 401 is connected with the upper left side in the casing 1 by bolts, the right side of ring slide rail 401 is connected with the inside of casing 1 by bolts. The upper right side of the ring slide rail 401 is provided with two first sliders 402 that slid...

Embodiment 3

[0043] A kind of talc powder evenly spreading device for tying shoelaces, such as Figure 1-9 As shown, it includes a box body 1, a lower hopper 3 and a lower material device 4, the middle part of the front side of the box body 1 has an opening 2, the top of the box body 1 is equipped with a lower hopper 3, and the upper part of the box body 1 is provided with a lower Material device 4.

[0044] The blanking device 4 includes an annular slide rail 401, a first slide block 402, a frame body 403, a ring gear 405, a first slide rail 406, a second slide block 407, a telescopic device 408, a baffle plate 409, a first spring 411, Blocking block 412, connecting block 413, first motor 414 and gear 415, the left side of ring slide rail 401 is connected with the upper left side in the casing 1 by bolts, the right side of ring slide rail 401 is connected with the inside of casing 1 by bolts. The upper right side of the ring slide rail 401 is provided with two first sliders 402 that slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com