Lifting machinery macrographic examination equipment

A macro-inspection and lifting machinery technology, which is applied in the direction of mechanical equipment, supporting machines, machine platforms/supports, etc., can solve the problems of not paying attention to safety management, inadequate inspection, and not easy to find, so as to achieve convenient operation and observation, prevent Leakage accident, the effect of reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

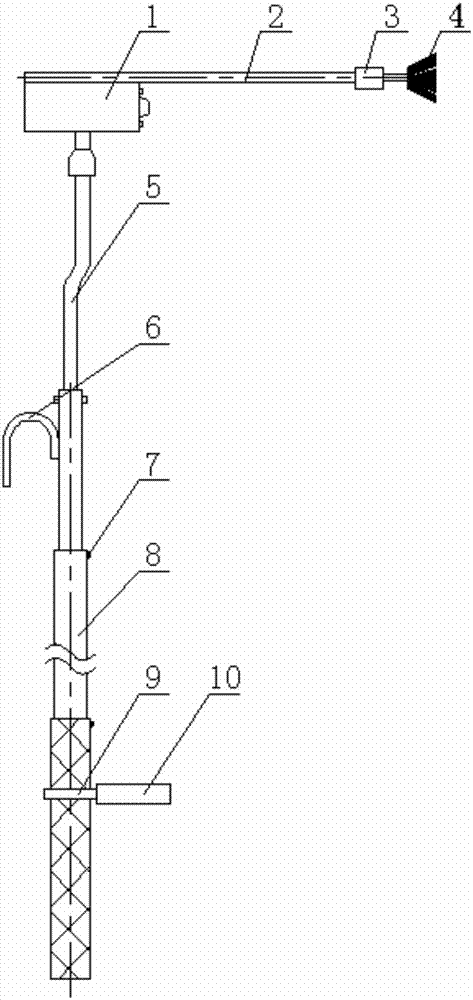

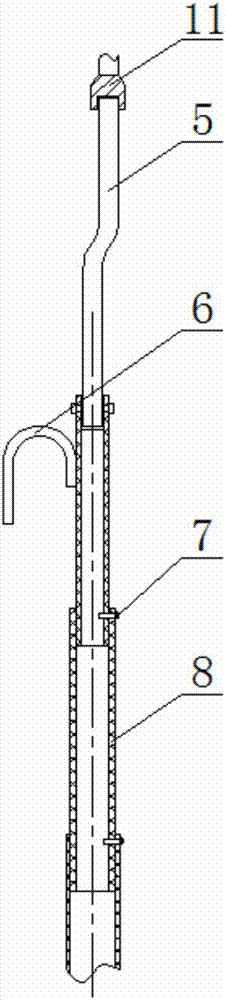

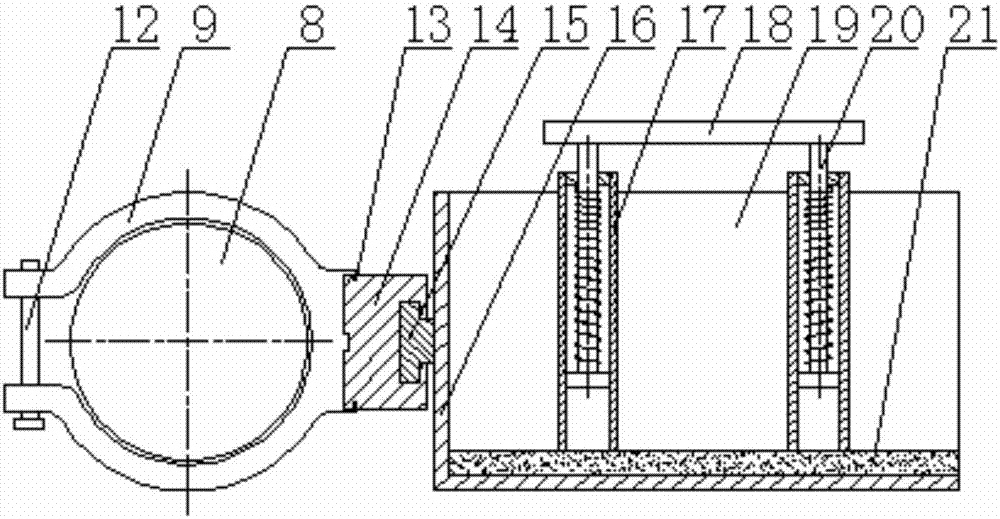

[0031] A kind of macro inspection equipment for hoisting machinery, comprising a telescopic rod 8, a universal hose 5, a camera lighting device 1, a cleaning brush 4 and a display screen clamping device 10, the telescopic rod is made of insulating composite material, and the telescopic rod is made of multiple The joints are composed of joint coaxial casing sleeves, and the buckles 7 are used to fix the two adjacent sleeve joints.

[0032] A fixed hook 6 is installed on the outer side of the upper end of the uppermost section of the sleeve pipe, the fixed hook is arc-shaped, and its opening is downward. The upper end of the uppermost bushing is coaxially connected to the universal hose. The specific connection st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com