A Method for Determining the Lamination Length of Transformer Magnetic Plate

A determination method, transformer technology, applied in instruments, measuring devices, etc., can solve problems affecting product quality, unable to meet the production needs of transformers, and magnetic plate laminations cannot be cut, so as to be easy to popularize and use, and solve the problem of magnetic flux leakage Large, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0016] A method for determining the length of a transformer magnetic plate lamination, establishing a coordinate model, obtaining the formulas for each curve of the shape of the magnetic plate lamination, and then calculating the length of each magnetic plate lamination; comprising the following steps:

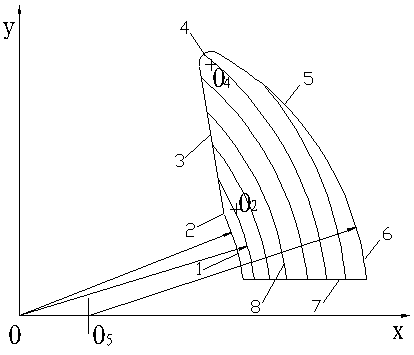

[0017] The shape of the magnetic plate laminate is composed of seven curves in sequence, which are curve one 1, curve two 2, curve three 3, curve four 4, curve five 5, curve six 6 and curve seven 7, of which curve one 1 and curve two 2. Curve four 4 and curve five 5 are circular arcs, O, O 2 , O 4 , O 5 It is the center of circle respectively; Curve three 3, curve six 6, curve seven 7 are straight line segments;

[0018] The arc curve 88 is the shape after the silicon steel sheets are stacked, and is a group of concentric arcs with the O poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com