Automatic counting bag connecting and folding equipment

An automatic counting and bag stacking technology, which is applied in stacking receiving devices, sending objects, thin material processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

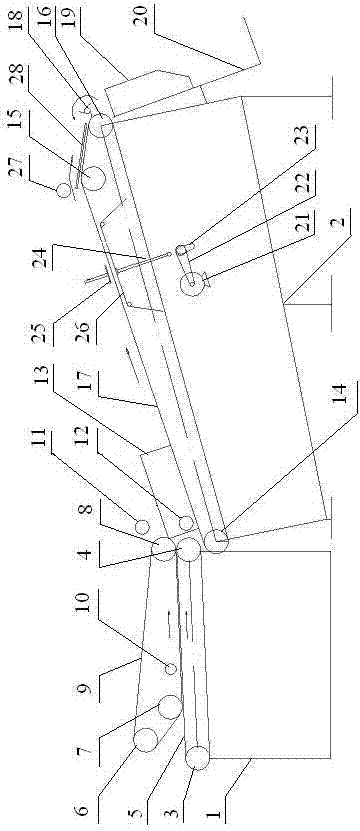

[0011] Such as figure 1 As shown, the automatic counting and stacking bag equipment is composed of three parts: a cutting bag piece conveying platform, a deceleration stacking conveying platform and a stacking collection platform: the cut bag piece conveying platform is composed of a support 1, a transmission roller, a cut bag piece Conveyor belt 5, pressing conveying belt 9 and static elimination rods 10, 11 etc., conveying rollers 3, 4 are respectively fixedly mounted on the front and rear of support 1, and the cutting bag sheet conveying belt 5 is driven to rotate by frequency conversion motor, and the compressing Conveyor belt 9 is arranged on the top of the cutting bag sheet conveying platform, and its lower layer belt is close to the upper layer of cutting bag sheet conveying belt 5, driven by the transmission rollers 6, 7, 8 driven by synchronous gears, and on the transmission rollers 7, 8 Static elimination rods 10, 11 are set in the front; the deceleration and stacki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com