Workpiece production line and workpiece screening system

A production line and workpiece technology, which is applied in the field of workpiece production lines and workpiece screening systems, can solve the problems of tilting of aluminum ingot stacks, large difference in thickness of aluminum ingots, and collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

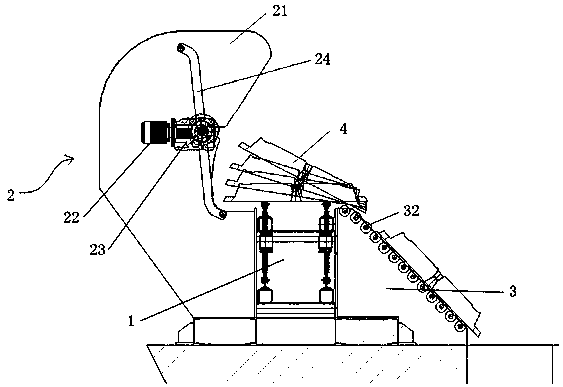

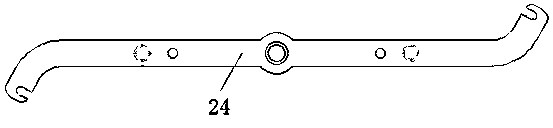

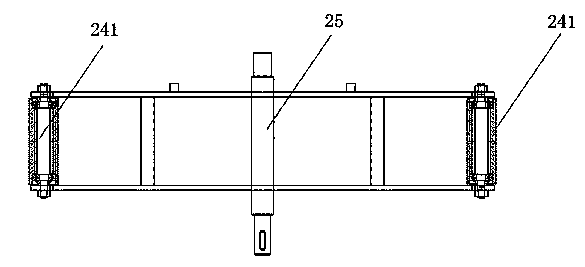

[0038] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0039] Embodiment 1 of the workpiece screening system of the present invention includes a workpiece bearing surface, a shifter and a detector, the detector moves relative to the workpiece bearing surface to detect workpieces on the workpiece bearing surface, and the shifter includes a shifter arm, The shifter moves relative to the workpiece bearing surface, the detector is connected with a controller for communication, and the controller is connected with the shifter to control and control the shifter to move one end of the designated workpiece upward through the shifter arm according to the detection feedback signal of the detector. Lift or press down to slide off the workpiece carrying surface.

[0040] In Embodiment 1, the detector moves relative to the workpiece bearing surface, and the dial machine and the workpiece bearing surface move relatively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com