A kind of hollow glass microbead and preparation method thereof

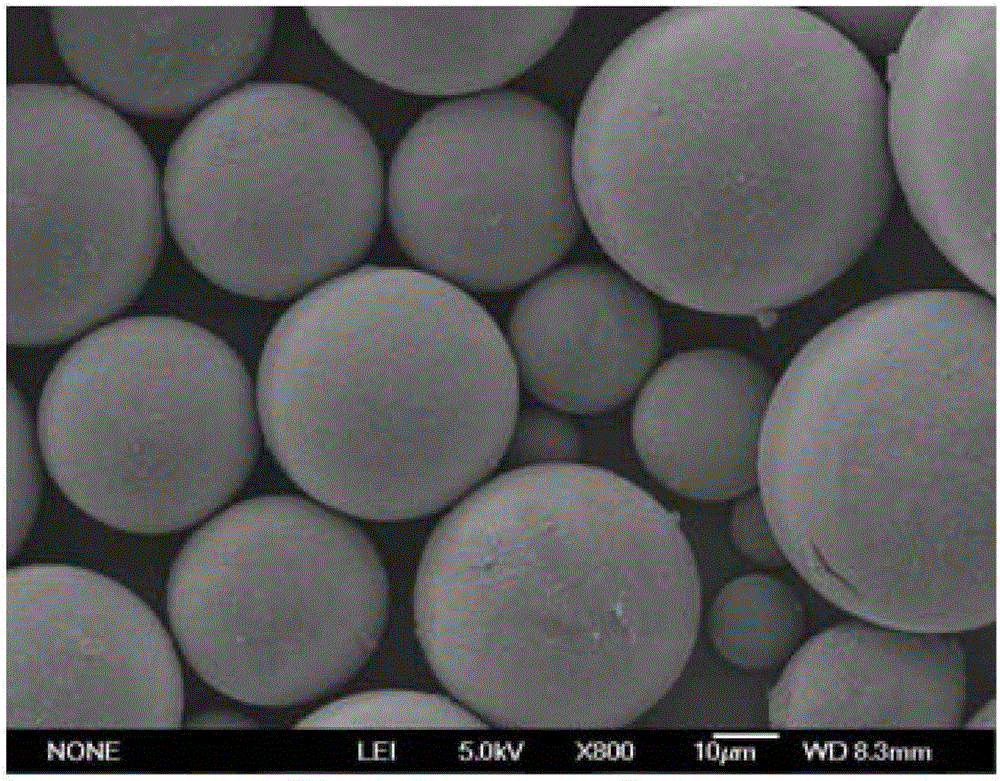

A hollow glass microbead and submicron technology, which is applied in the field of cement slurry additive materials, can solve the problem that the particle size of hollow microbead products cannot be accurately controlled, the hollowness and wall thickness cannot be well controlled, and the preparation of hollow microbead products can not be solved. The method is cumbersome and other problems, to achieve the effect of tight stacking, high strength, and high resistance to high pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

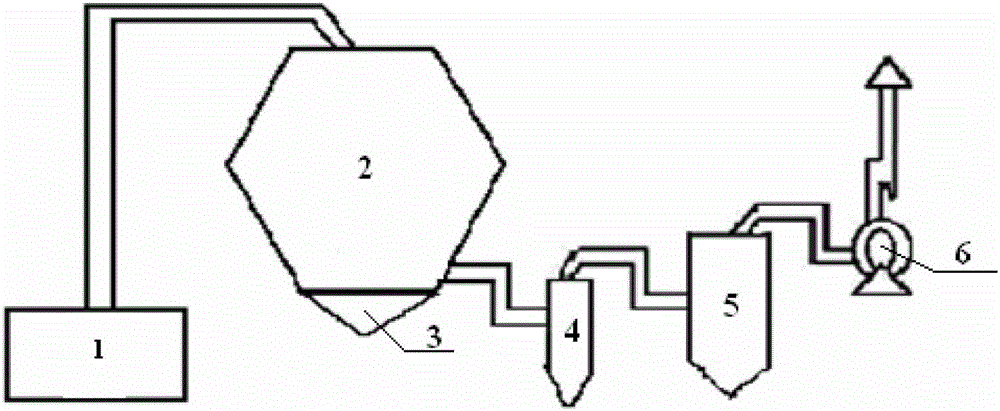

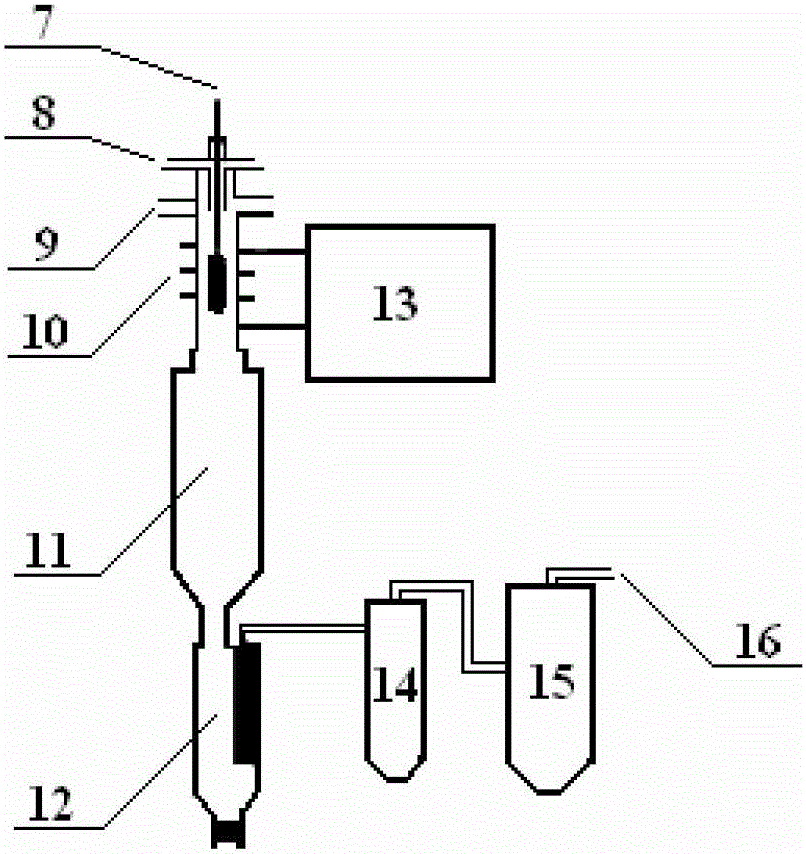

[0046] (1) First mix 46kg of nano-sized silica (average particle size 30nm), 25kg of micron-sized silica (average particle size of 2 microns), 22kg of sub-micron-sized silicon oxide (average particle size of 120nm), 1kg of alumina, iron oxide 0.1kg, zirconia 1.8kg, boron oxide 4.2kg, zinc oxide 0.2kg, lithium oxide 0.3kg, barium oxide 0.2kg, sodium silicate 20kg after dry mixing, use 300kg water in a high-speed mixer to make a uniform slurry.

[0047] (2) Pump the above slurry into a centrifugal spray granulator to granulate the precursor of hollow glass microspheres through a circulating pump, wherein the centrifugal speed is 20,000rpm; the drying temperature during granulation is 260°C, and the inlet temperature of the dryer is 120°C °C, the outlet temperature is 250 °C. Under the action of the induced draft fan, the spheres coming out of the drying tower are respectively deposited in the bottom of the tower, the cyclone collection bin and the bag collection bin according to...

Embodiment 2

[0050] (1) First mix 42kg of nano-sized silica (average particle size 40nm), 26kg of micron-sized silica (average particle size of 2 microns), 26kg of submicron-sized silicon oxide (average particle size of 120nm), 2kg of alumina, iron oxide 0.1kg, zirconia 2kg, boron oxide 3.6kg, zinc oxide 0.2kg, lithium oxide 0.2kg, barium oxide 0.2kg, sodium silicate 30kg after dry mixing, use 400kg water in a high-speed mixer to make a uniform slurry.

[0051] (2) Pump the above slurry into a centrifugal spray granulator to granulate the precursor of hollow glass microspheres through a circulating pump, wherein the centrifugal speed is 21000rpm; the drying temperature during granulation is 260°C, and the inlet temperature is 120°C. The outlet temperature was 250°C. Under the action of the induced draft fan, the spheres coming out of the drying tower are respectively deposited in the bottom of the tower, the cyclone collection bin and the bag collection bin according to their weight and ar...

Embodiment 3

[0054] (1) First mix 38kg of nano-sized silicon dioxide (average particle size 40nm), 27kg of micron-sized silicon dioxide (average particle size of 2 microns), 27kg of submicron-sized silicon oxide (average particle size of 120nm), 2kg of aluminum oxide, iron oxide 0.1kg, zirconia 2kg, boron oxide 3kg, zinc oxide 0.3kg, lithium oxide 0.3kg, barium oxide 0.3kg, sodium metasilicate 20kg after dry mixing, use 500kg water in a high-speed mixer to make a uniform slurry.

[0055] (2) Pump the above slurry into a centrifugal spray granulator to granulate the precursor of hollow glass microspheres through a circulating pump, wherein the centrifugal speed is 21000rpm; the drying temperature during granulation is 260°C, and the inlet temperature is 120°C. The outlet temperature was 250°C. Under the action of the induced draft fan, the spheres coming out of the drying tower are respectively deposited in the bottom of the tower, the cyclone collection bin and the bag collection bin accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com