Membrane tension automatic adjustment device and air-cushion machine containing same

An automatic adjustment, air-cushion machine technology, used in transportation and packaging, winding strips, cardboard items, etc., can solve problems such as reducing work efficiency, affecting inflation, heat sealing effect, and reducing film tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

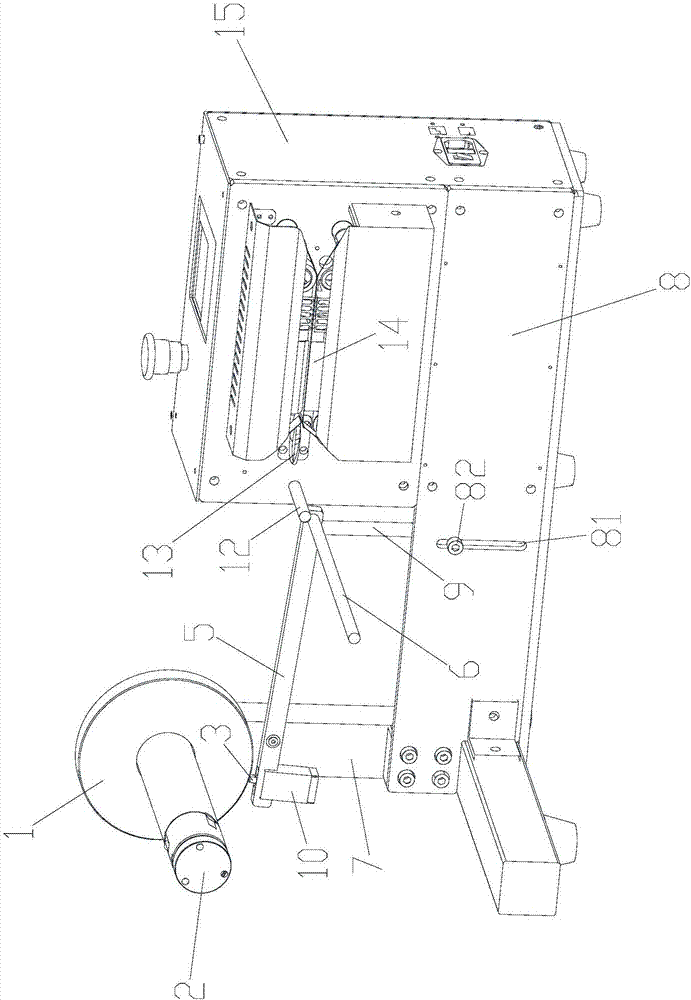

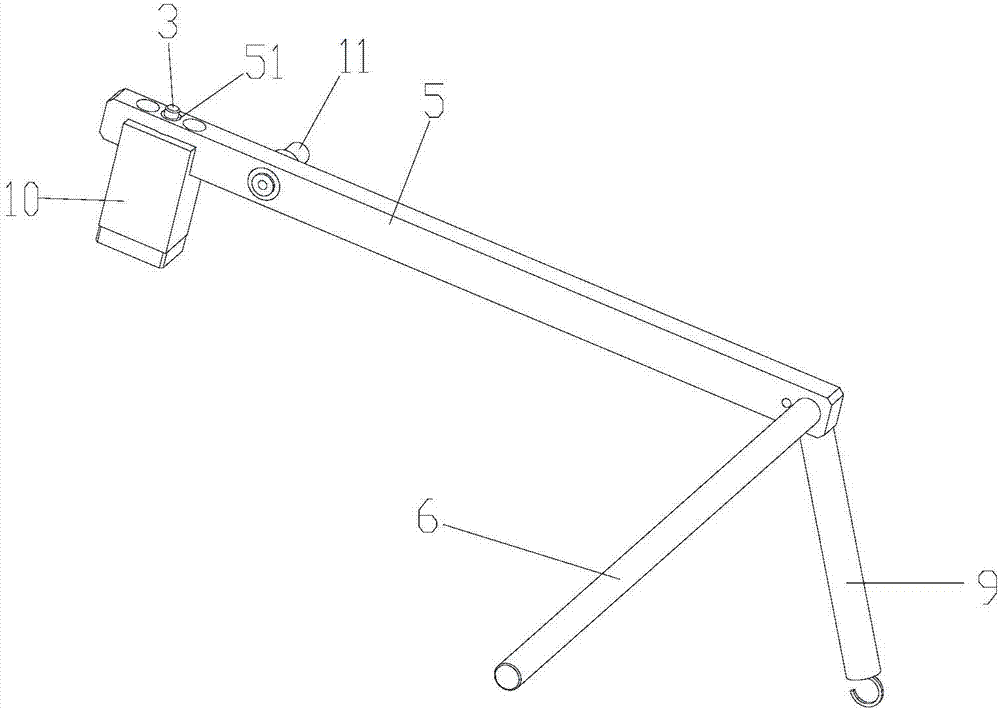

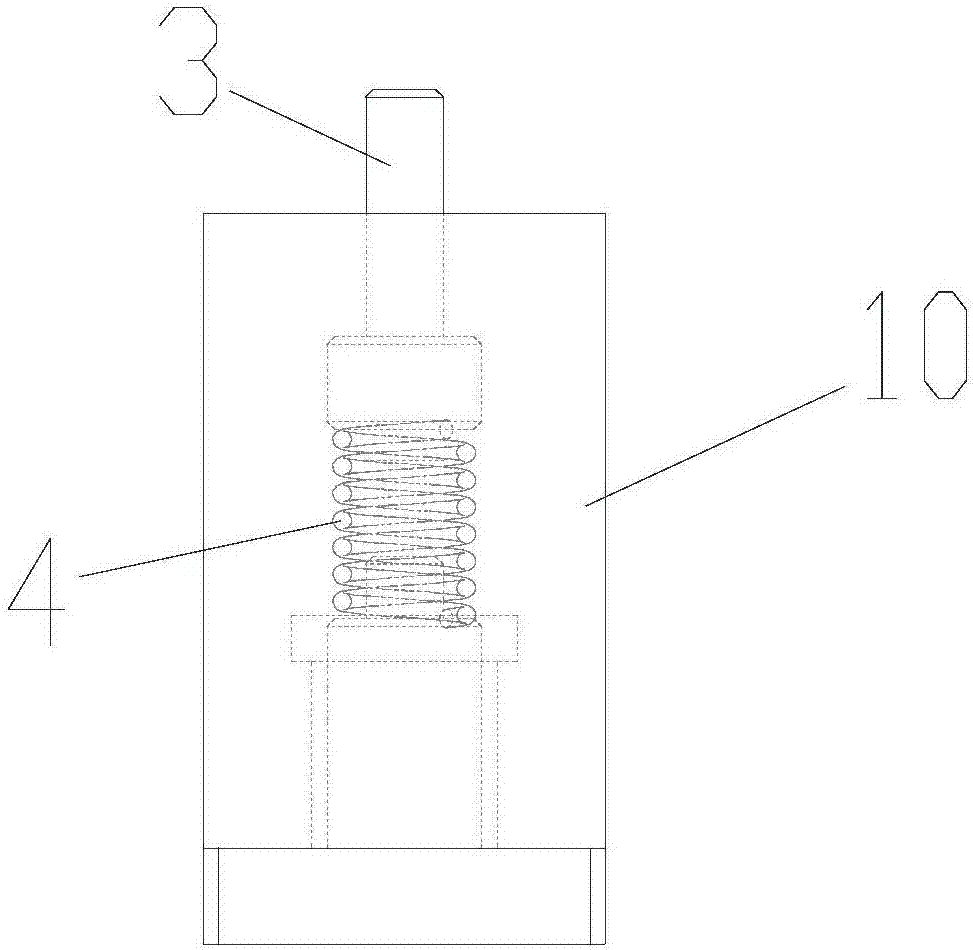

[0018] Figure 1 to Figure 3 Schematically shows the structure of an automatic membrane tension adjustment device and an air cushion machine including it according to an embodiment of the present invention.

[0019] Such as Figure 1 to Figure 3 As shown, an automatic membrane tension adjustment device includes a friction plate 1 , a roller 2 , a friction column 3 , a compression spring 4 , a swing lever 5 , a compression lever 6 and a bracket 7 . In addition, the film tension automatic adjusting device may also include a fixed frame 8 , a tension spring 9 , an adjusting bolt 82 , a fixed box 10 and a rotating shaft 11 .

[0020] Such as figure 1 As shown, one end of the drum 2 is installed on the top of the bracket 7, and the drum 2 is rotatably connected with the bracket 7, that is, the drum 2 can rotate.

[0021] Such as figure 1 As shown, the frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com