Hydrophilic interface manufacturing method and system for holding biological tissues

A technology of biological tissue and manufacturing method, applied in the direction of instruments, computer materials science, molecular design, etc., can solve the problems of tissue damage, slippage, etc., and achieve the effect of non-damage clamping and pulling, and precise design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In the present invention, the maximum slipping force is defined as the minimum clamping force that can hold the biological tissue along the vertical direction of the tissue surface and prevent the tissue from slipping off from the forceps, and the minimum damage force is defined as the ability to clamp the living tissue along the vertical direction of the tissue surface. The above-mentioned biological tissue is the minimum clamping force that causes tissue damage; since the maximum slipping force and the minimum damage force are related to the clamping force, the clamping force is defined as the force that pulls up or unfolds the tissue horizontally.

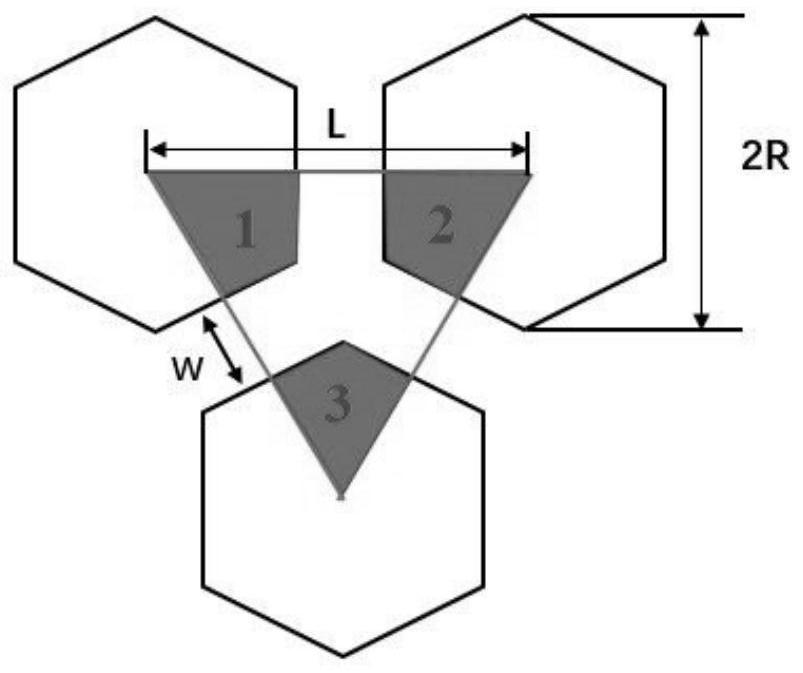

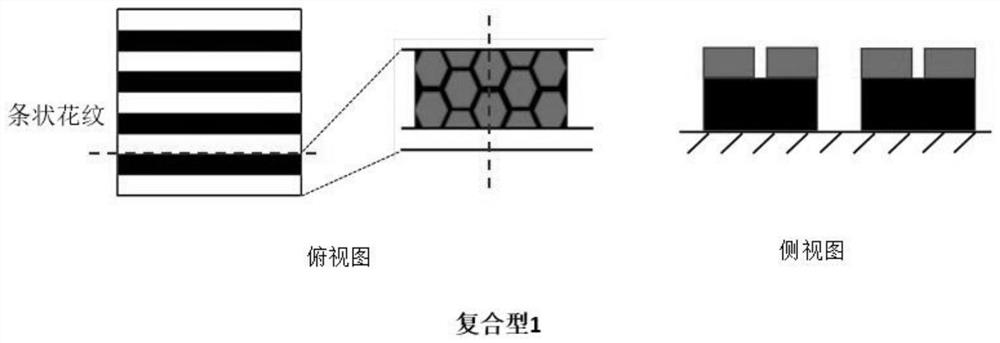

[0028] The source of the adsorption force of the hydrophilic interface is the liquid film tension, the viscosity-dependent hydrodynamic pressure and the intermolecular force (Van der Waals force), among which the liquid film tension plays a major role, and the liquid film tension is affected by the structure of the hydrophi...

Embodiment 2

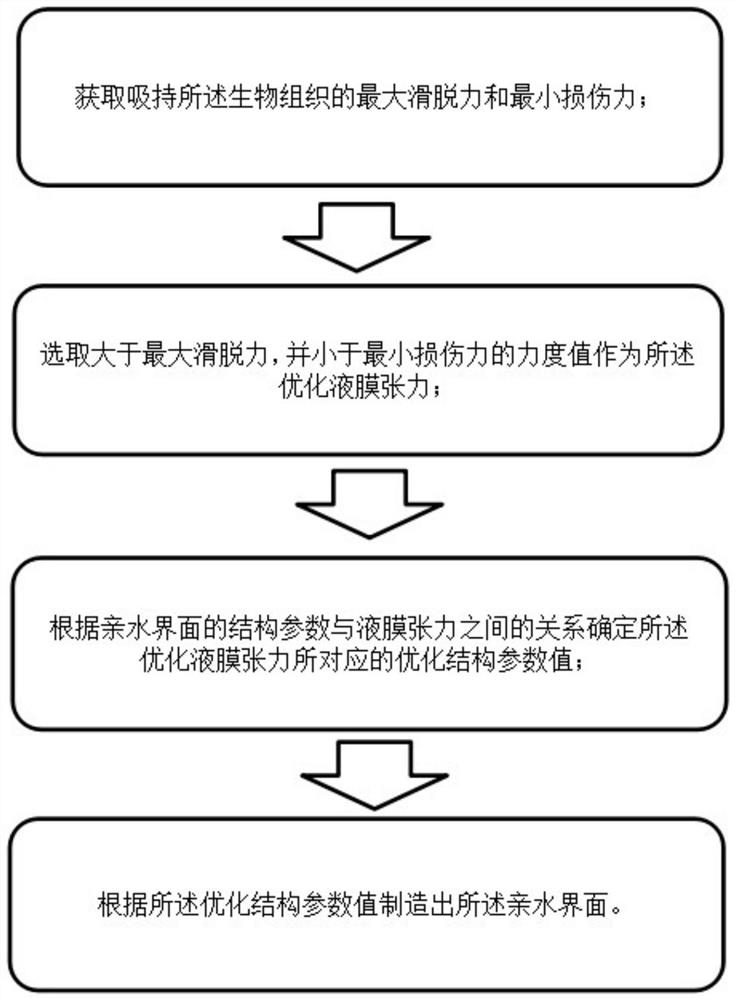

[0035] Embodiment 2 is an extended embodiment of the embodiment, which is different from the embodiment 1 in that the manufacturing method of the hydrophilic interface for absorbing biological tissue is refined, and specifically includes the following steps:

[0036] (1) Obtain the maximum slipping force and the minimum damage force for holding the biological tissue:

[0037] Step 1: Use the pliers to clamp the biological tissue with a clamping force (such as 1N) of the initial force along the vertical direction of the surface of the biological tissue, and observe whether the forceps under this force can hold the biological tissue;

[0038] 1A: If the biological tissue cannot be clamped (that is, when there is a visible movement between the forceps head and the tissue), gradually increase f on the basis of the initial force α (such as 0.5N), and increase f with each α The final clamping force clamps the biological tissue until increasing f α The final clamping force clamps t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com