Marine operation lamp

A work light and power supply technology, applied in lighting devices, fixed lighting devices, electric light sources, etc., can solve the problems of long time to sea and dangerous work lights, and achieve the purpose of preventing accidents, improving joint stability and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

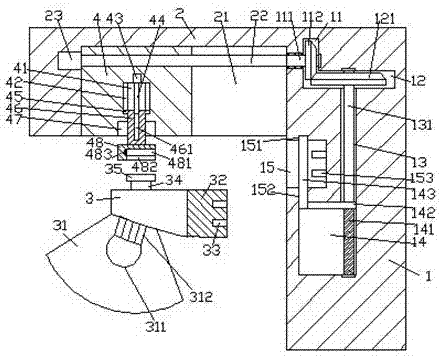

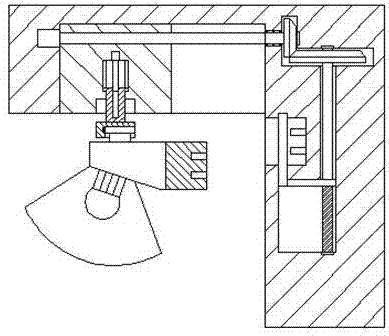

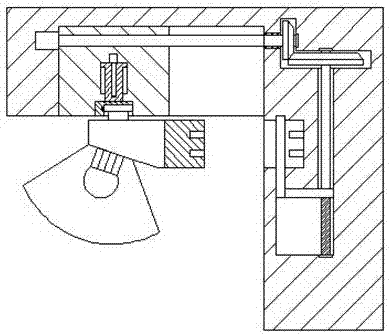

[0023] Such as Figure 1-Figure 7 As shown, a marine working light of the present invention includes a power feeding device 1, a sliding part 2 fixedly installed on the upper left side of the power feeding device 1, and a working light 3, and the bottom right side of the sliding part 2 is A sliding groove 21 is provided in the side surface, and a first screw 22 extending left and right is arranged in the sliding groove 21, and the left side of the first screw 22 is connected with the first electric rotating machine 23, and the first screw 22 The upper fitting is connected with a locking block 4 for locking and fitting connection with the work light 3, and the locking block 4 is in contact with the front and back of the sliding groove 21 and is connected by sliding fitting. The sliding groove 21 The power feeding device 1 on the right is provided with a first conduction cavity 11 extending up and down, and the bottom of the first conduction cavity 11 is penetrated with a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com