Ash removal structure of dust collector and dust collector

A vacuum cleaner and dust cleaning technology, which is applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve problems such as inconvenient cleaning methods, easy slipping of the dust collection bucket, and unstable connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

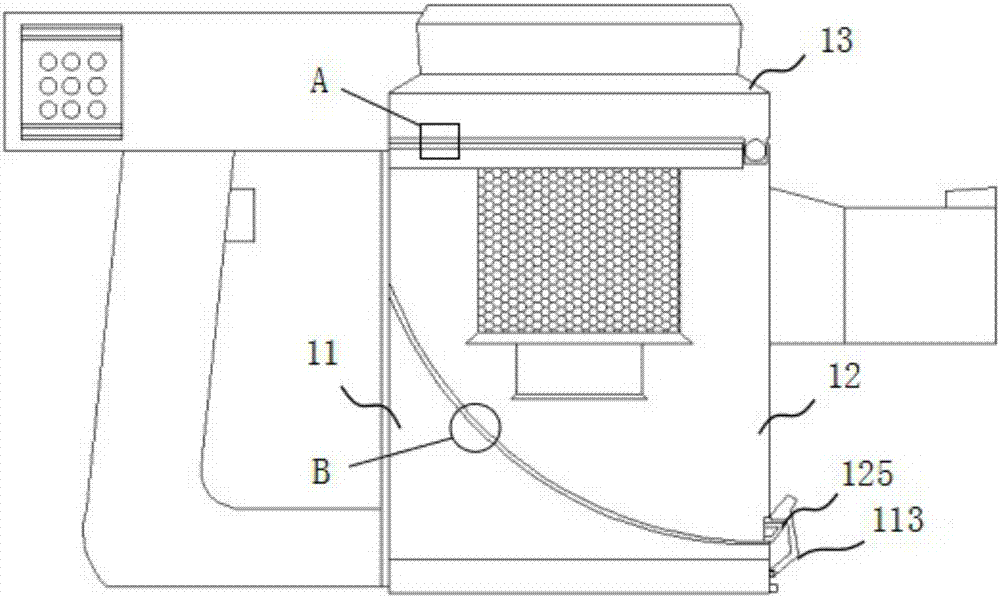

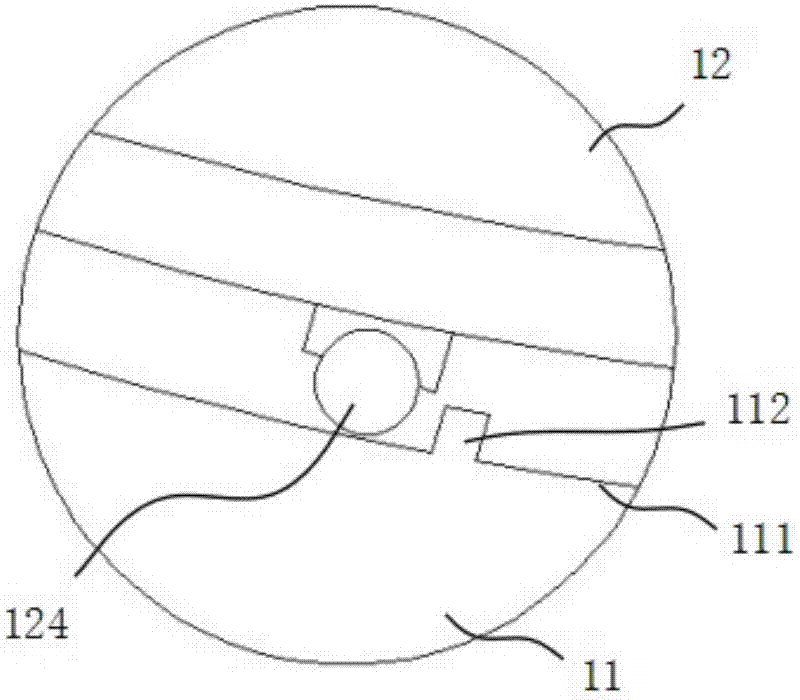

[0053] Such as figure 1 -4, in one embodiment of the present invention, the upper end surface of the base 11 forms a first arc-shaped surface, a third connecting groove 111 is formed on the first arc-shaped surface, and the dust collecting part 12 The lower end surface of the lower end surface forms a second arc surface, forms a third connection protrusion 123 on the second arc surface, and connects a pulley 124 on the third connection protrusion 123, so that the pulley 124 is on the The third connection groove 111 is slidingly connected, and a limit block 112 is also provided in the third connection groove 111, so that when the pulley 124 slides in the third connection groove 111, the limit block 112 The sliding position of the pulley 124 is limited; the upper end surface of the dust collecting part 12 forms a first connecting groove 121, and the lower end surface of the filtering part 13 forms a first connecting protrusion 131, and the first connecting protrusion 131 is con...

Embodiment 2

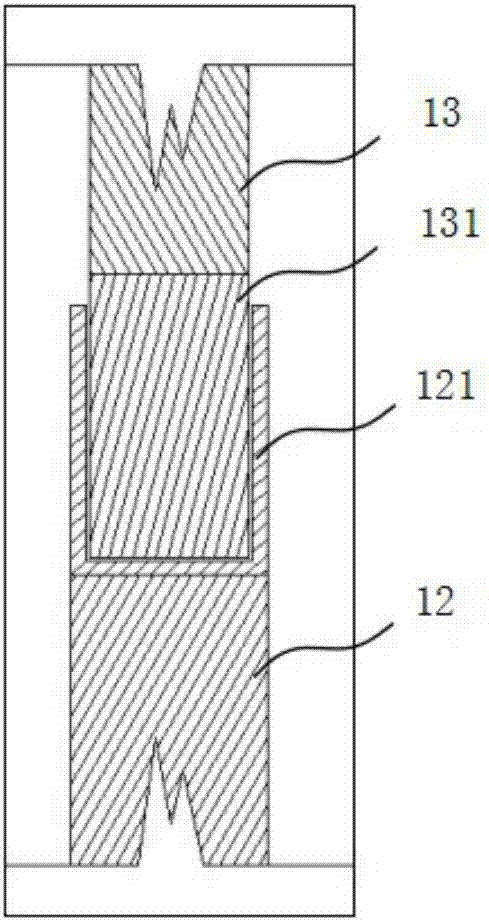

[0058] Such as Figure 5 -6, in one embodiment of the present invention, the difference from Embodiment 1 is that in order to connect the first connecting protrusion 131 on the filter part 13 with the first connecting groove on the dust collecting part 12 121, the second connecting groove 132 is set on the first connecting protrusion 131, and the second connecting protrusion 122 is set in the first connecting groove 121, so that the upper part of the dust collecting part 12 The end surface can be firmly combined with the lower end surface of the filter part 13 to prevent dust from leaking. Other structures and usage modes of this embodiment are the same as those of Embodiment 1.

[0059] The dust cleaning structure of the vacuum cleaner provided by the present invention, the bottom end surface of the dust collecting part and the top end surface of the base are both connected by an arc structure with the same radian, so that the bottom end surface of the dust collecting part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com