Grain sampler pipe head

A technique for sampling and tube, which is applied in the field of the tube head of the food sampler, can solve the problems of inconvenient use of the tube head of the sampler, and achieves the effects of speeding up the fluidity, reasonable structure and not easy to block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

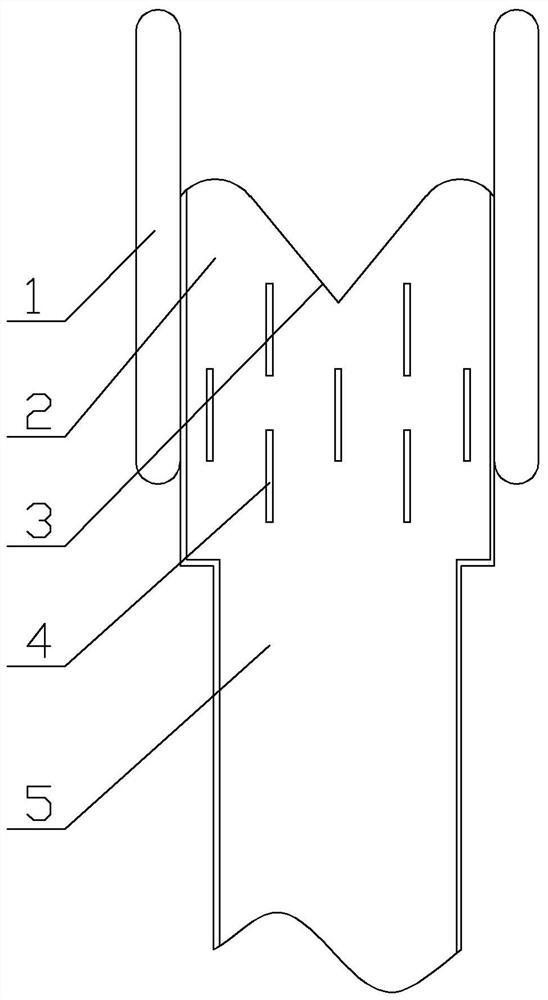

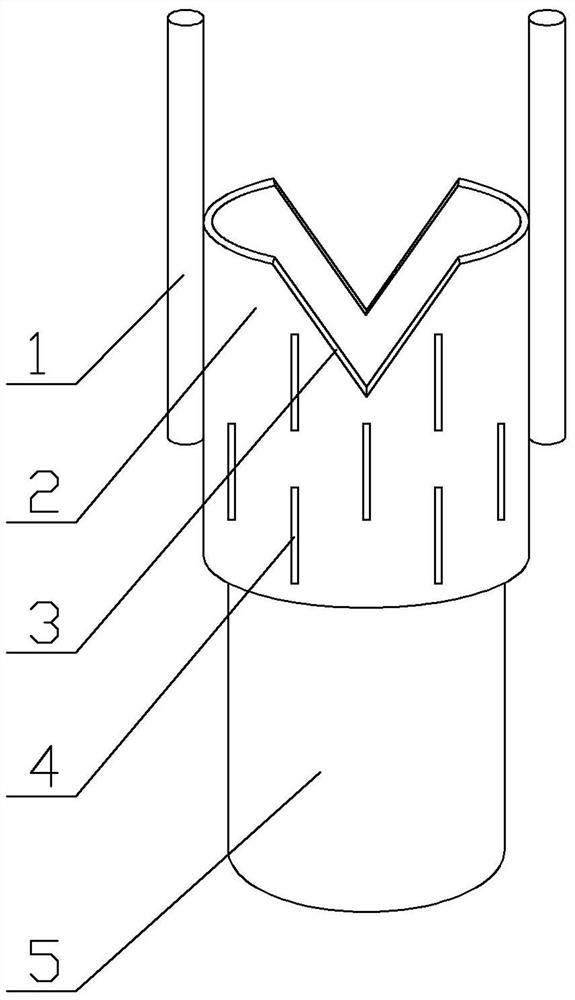

[0017] Embodiment 1: According to figure 1 and figure 2 , a tube head of a grain sampler, which includes a tube head 2 sleeved at the end of the sample tube 5, and the other end of the tube head is a top nozzle; both sides of the tube head are respectively provided with extended Rib 1; the top of the elongated rib is higher than the top nozzle of the pipe head; the front and rear sides of the top nozzle of the pipe head are respectively provided with openings 3; the circumference of the pipe is provided with alternately distributed strip air grooves 4.

[0018] The pipe head is a galvanized metal pipe or a stainless steel pipe, which is welded to one end of the sample pipe.

[0019] The elongated ribs are provided with 2-4 pieces, which are welded on the outer wall of the pipe head, and the top of the elongated ribs is 5-15cm higher than the nozzle at the top of the pipe head.

[0020] When the sample tube is inserted into the bottom of the granary, the extension rib first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com