Shield of garden pit digging machine

A technology for digging machines and shields, which is applied in the field of garden digging machine shields, can solve the problems of inconvenient use of garden digging machine shields, and achieve the effects of excellent performance, increased specific surface area, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

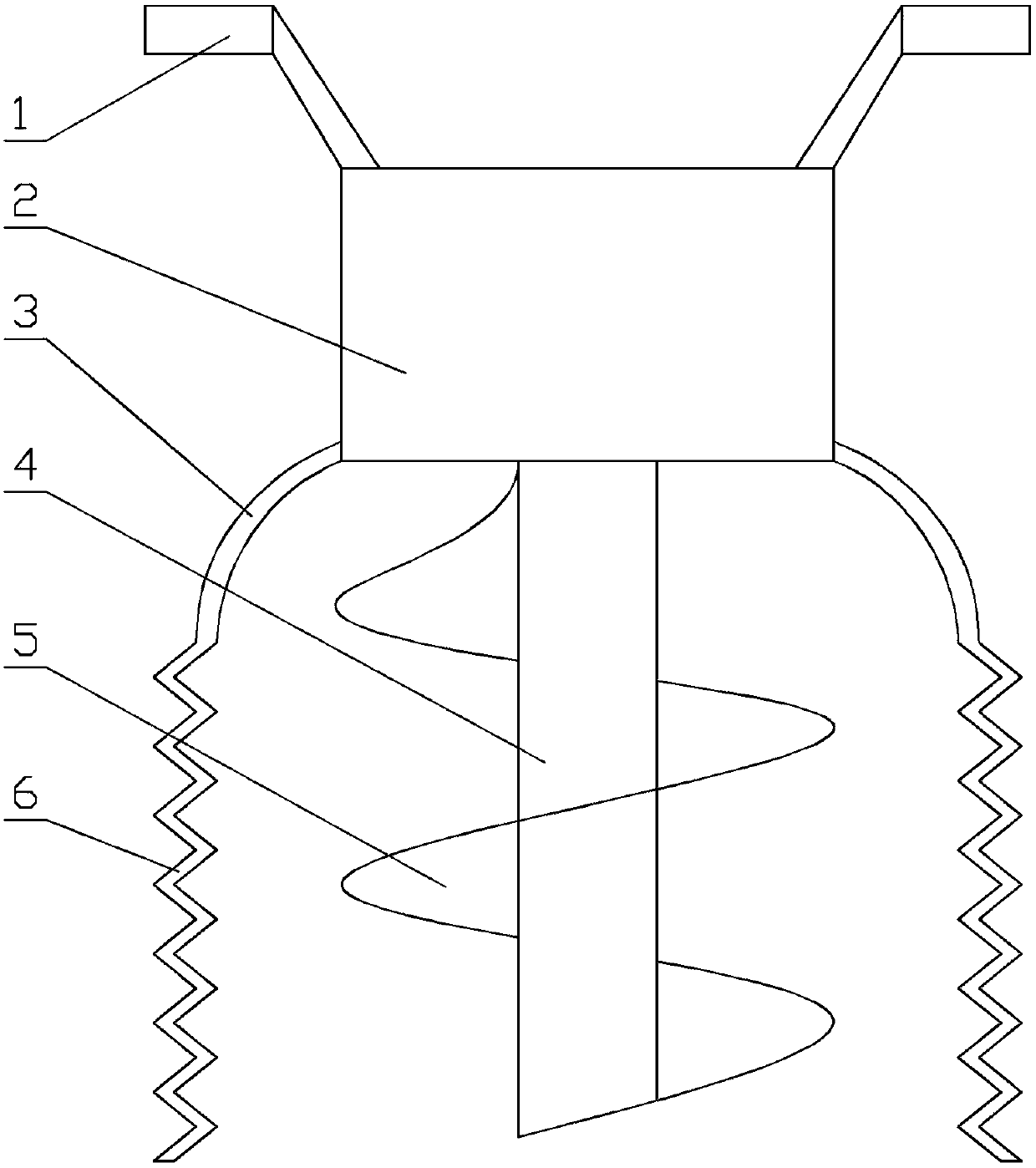

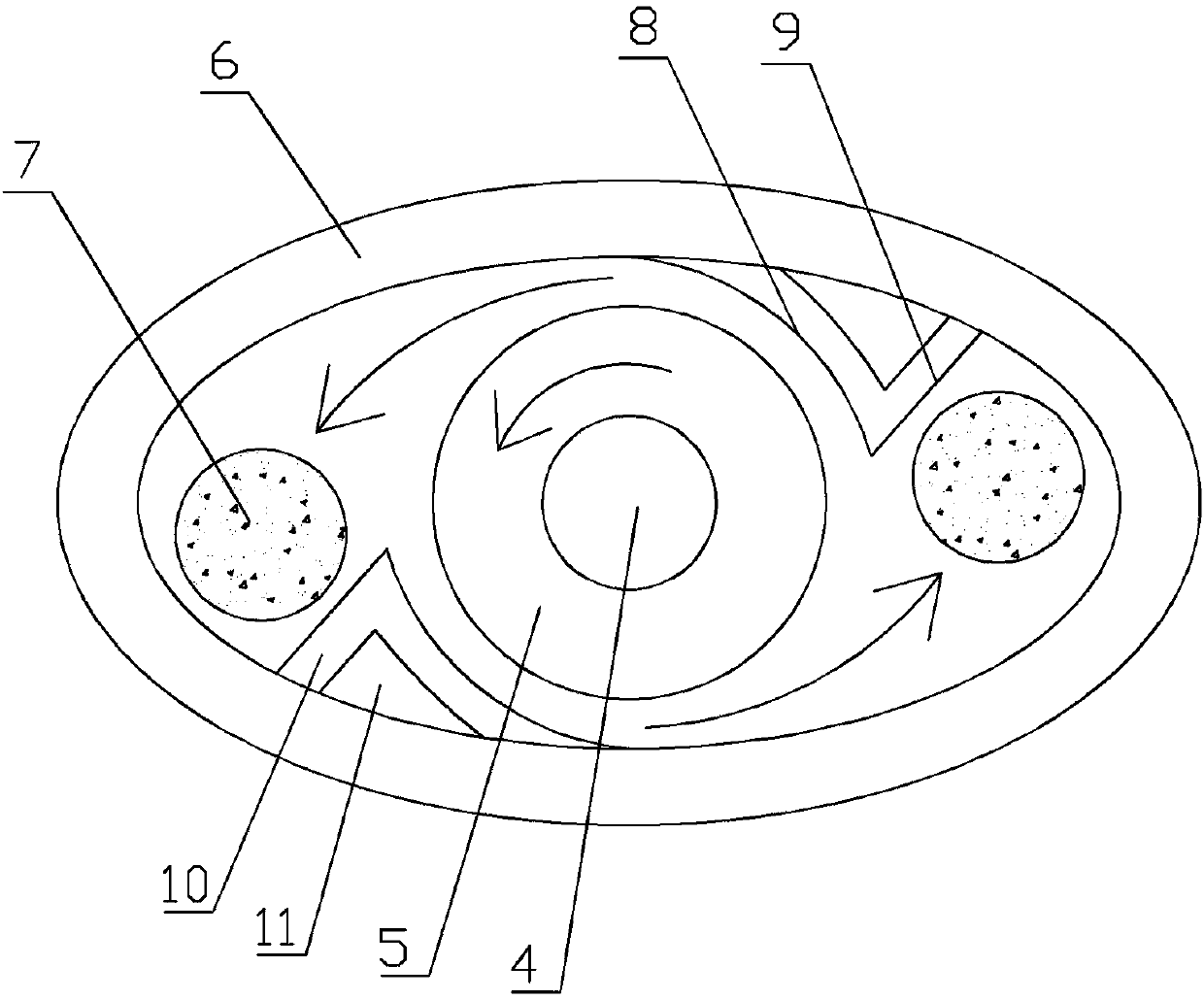

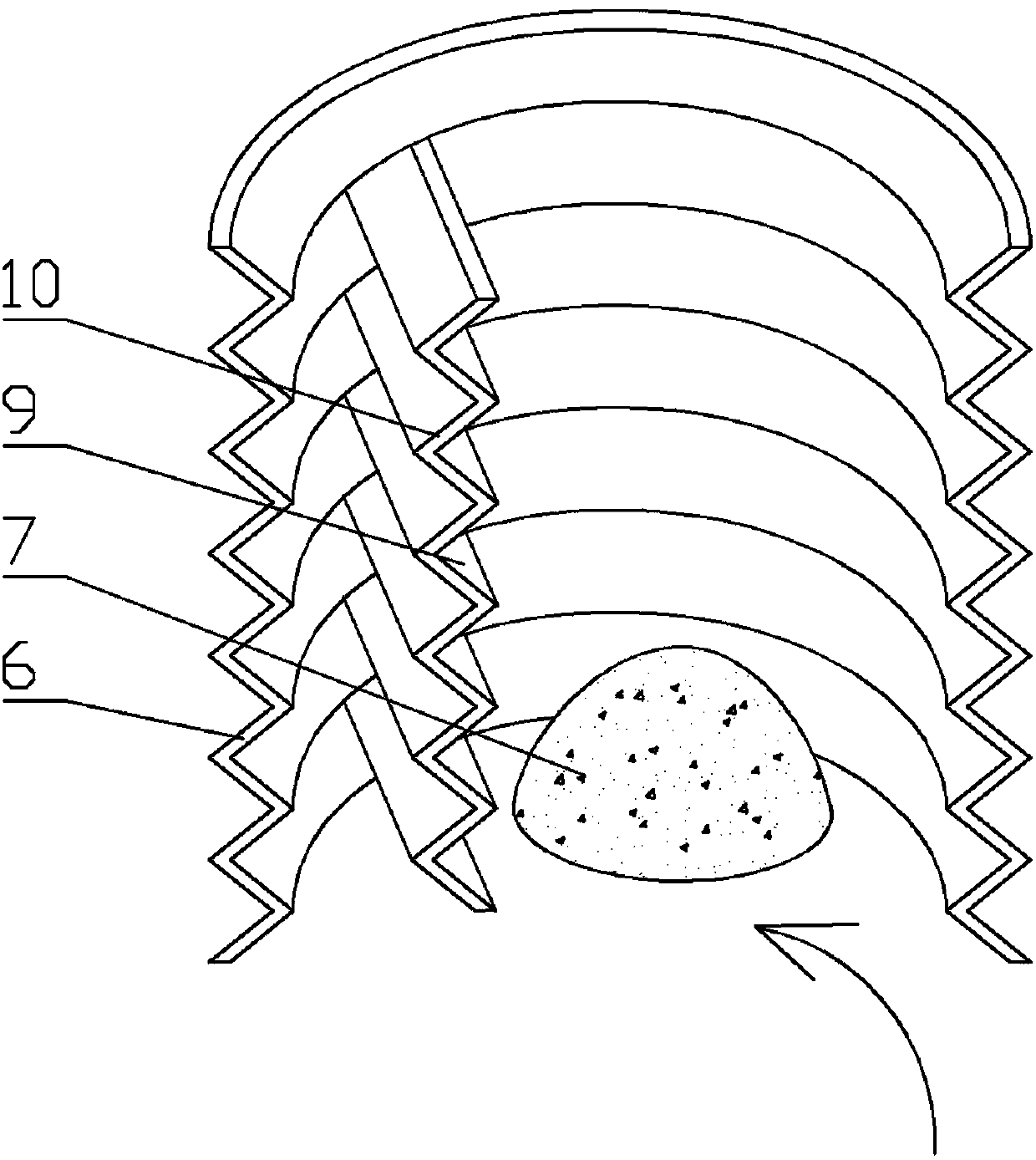

[0029] according to Figure 1-Figure 3 , a garden digging machine shield, which includes a fuel engine 2 with handles 1 at both ends; a transmission shaft 4 for transmission connection is provided below the fuel engine 2; a helical tooth 5 is provided on the transmission shaft; A circle of oval upper cover plate 3 is arranged around the fuel engine, and the drive shaft and helical teeth are located in the middle of the upper cover plate; an oval lower sheath 6 is provided below the upper cover plate; the lower sheath adopts Multi-section folding type; the inside of the lower sheath is provided with two sets of vertically distributed inner lining blocks 10, which are respectively in the small-angle arc ends of the two ends of the lower sheath; the inner lining blocks are multi-section folding like the lower sheath formula; the inner liner block is provided with two surfaces, one is a blocking surface 9 vertically connected with the inner wall of the lower sheath 6, and is oppos...

Embodiment 2

[0038] according to Figure 4 , the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the transmission shaft and the helical teeth 5 are located at one end of the elliptical upper cover plate 3 and the lower sheath 6; the inner liner block 10 is provided with a set of , located at the other end of the lower sheath 6.

[0039] A group of inner lining blocks 10 are set, and the scattered soil 7 is piled into a pile after excavation, which is convenient for later landfill, and the area covered by the upper cover plate 3 and the lower sheath 6 and its own area are all smaller compared with the prior art , easy to carry and move.

Embodiment 3

[0041] The lower sheath 6 and the inner liner block 10 of the present invention are integrated plastic materials, which are prepared according to the following process:

[0042] 1) Weigh each raw material according to parts by weight, including: 100 parts of ABS resin, 20 parts of phenolic resin, 10 parts of polycarbonate, 10 parts of polyhexamethylene adipate, 10 parts of attapulgite, and 5 parts of polyvinylpyrrolidone , 5 parts of silicon carbide, 3 parts of borax, 3 parts of dioctyl phthalate, 2 parts of glass fiber, 2 parts of silane coupling agent KH-550, 1 part of talcum powder;

[0043] 2) Put silicon carbide and borax in a ball mill for 12 hours, then pass through a 100-mesh sieve, collect the under-sieve, and obtain component A;

[0044]3) Put the attapulgite into a heating furnace for high-temperature calcination. The temperature in the heating furnace is 500°C, and the calcination time is 30 minutes. Take it out, cool it to room temperature, and then add it to twic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com