Manufacturing method of touch display module

A technology of touch display and production method, which is applied in the direction of chemical instruments and methods, lamination auxiliary operation, data processing input/output process, etc., which can solve the problems such as the difficulty of realizing narrow borders, so as to improve market competitiveness and reduce assembly Section, reduce the effect of assembly tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

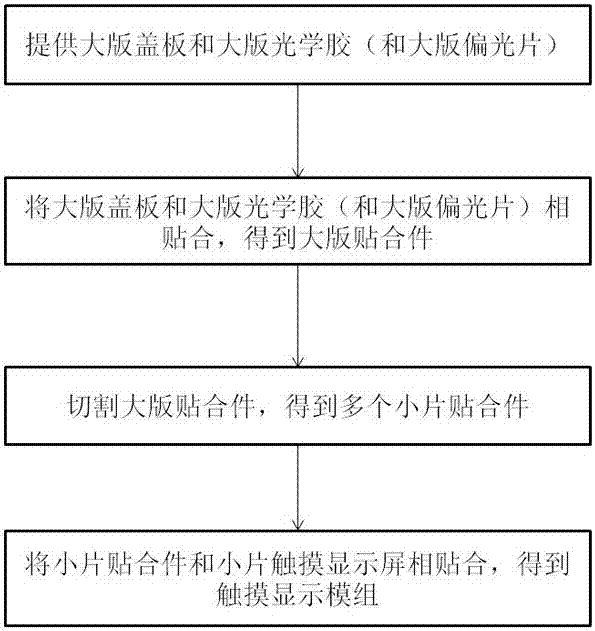

[0024] Such as figure 1 As shown, a manufacturing method of a touch display module includes the following steps:

[0025] Provide at least a large version of the cover plate and a large version of the optical glue, preferably, the size of the decorative cover plate and the large version of the optical glue are the same;

[0026] Bonding the large-format cover plate and the large-format optical adhesive together to obtain a large-format bonding piece;

[0027] Cutting the large-format bonding parts to obtain a plurality of small bonding parts;

[0028] A small piece of touch display screen is provided, and the small piece of bonding member is bonded to the small piece of touch display screen to obtain a touch display module.

[0029] In the prior art, the production method of the touch display module generally adopts the method of firstly cutting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com