Heat sink

A technology for heat dissipation devices and bases, which is applied to pump devices, parts of pumping devices for elastic fluids, cooling/ventilation/heating transformation, etc., and can solve complex circuit design, offset of corresponding pole pieces, high production cost, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

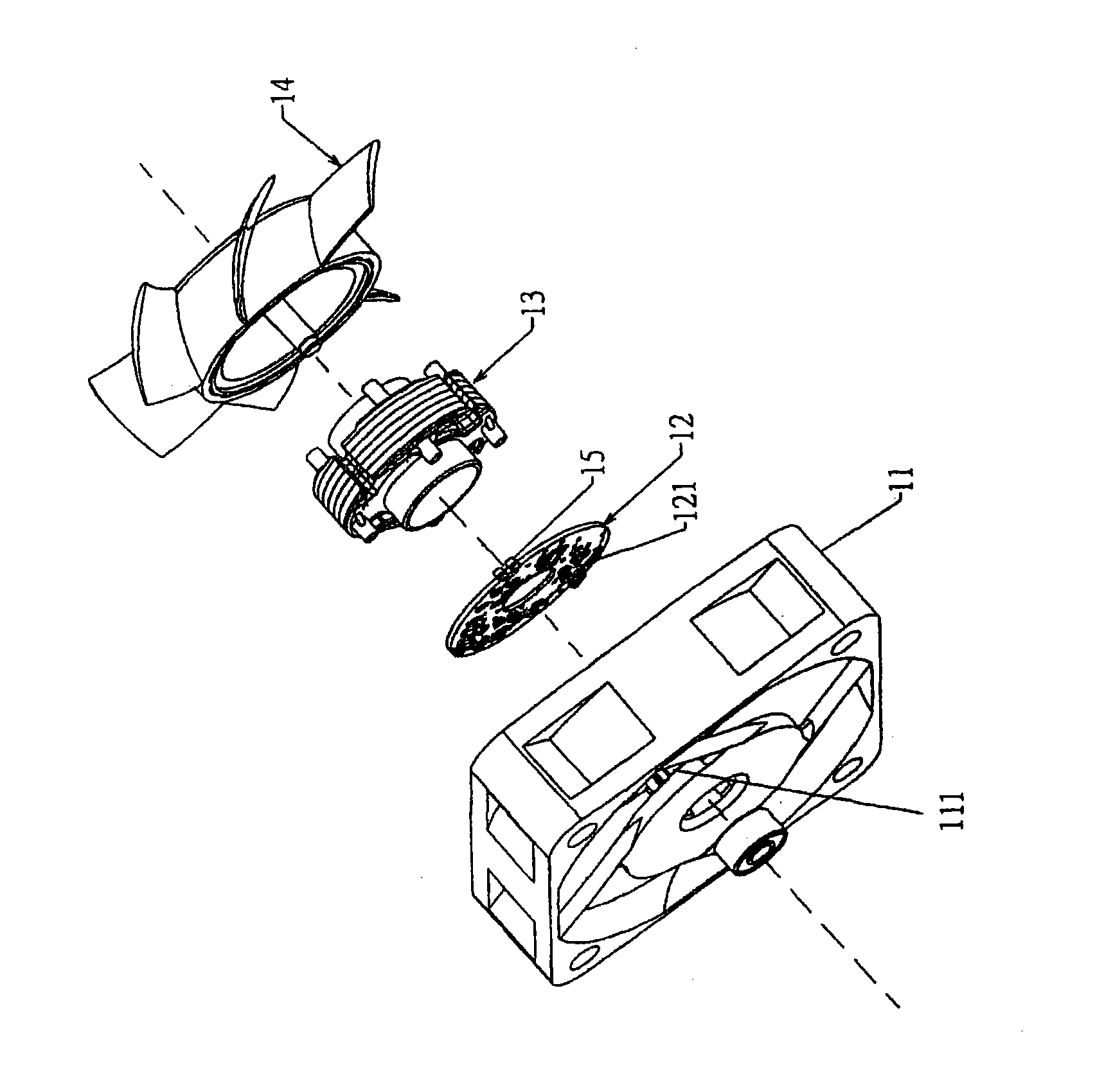

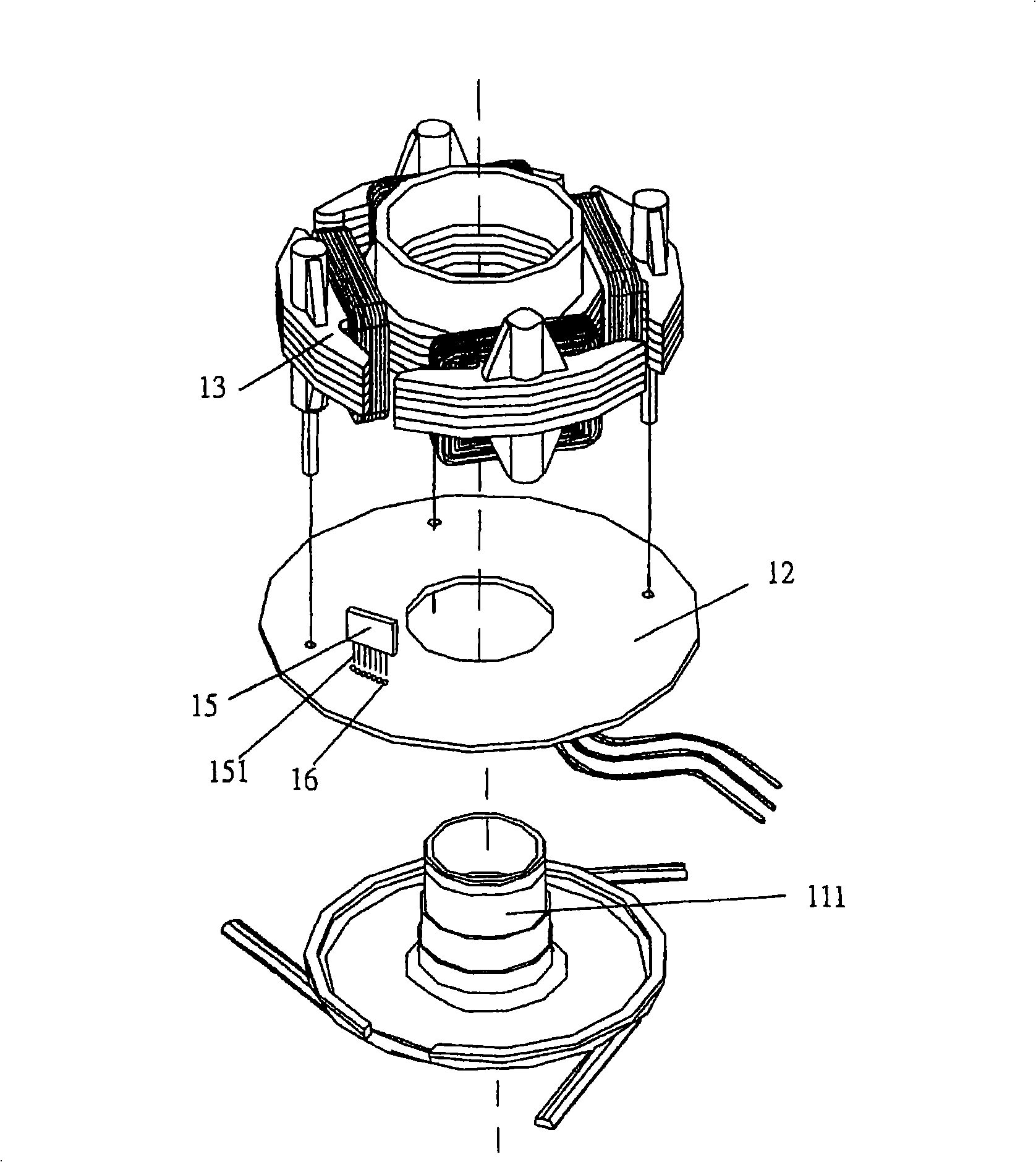

[0046] This case can be understood more deeply through the following diagrams and detailed descriptions.

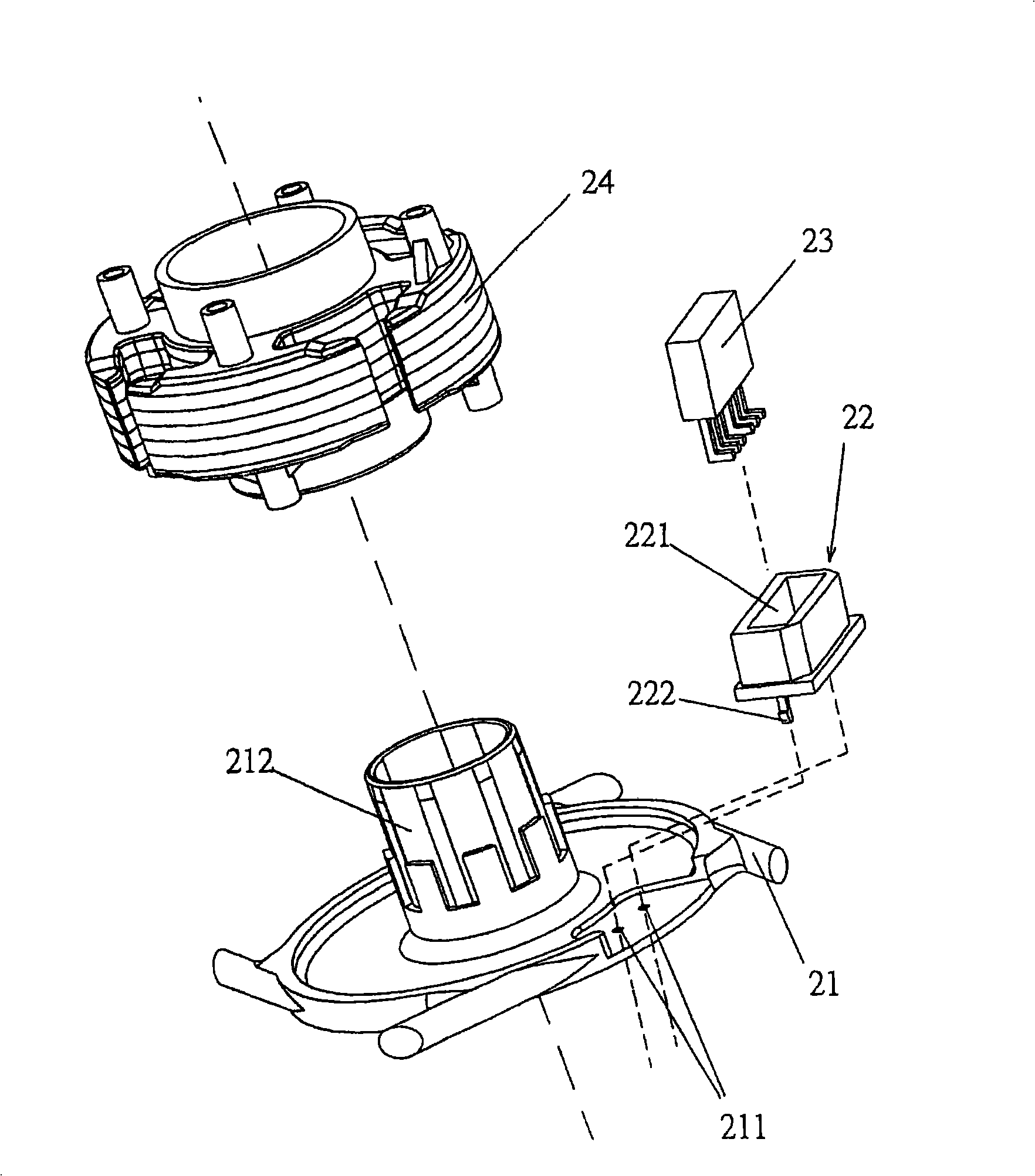

[0047] The invention discloses a motor control element and its fixing seat applied to a cooling fan, which uses a single drive control element to sense the phase change of the magnetic pole of the motor and control the operation of the fan motor. First, see figure 2 , which is the first preferred embodiment of the positioning method of the motor-driven control element of the present application. According to a conception of the present invention, the fixing seat 22 is substantially a square frame seat, which has a slot 221, which is formed according to the size and shape of the drive control element, for accommodating the drive control element to be inserted into There are hooks 222 on both sides of the bottom surface of the fixing seat, which can be fastened to the fastening holes 211 on the fan frame base 21 of the cooling fan, so that the fixing seat can be fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com