Method for enhancing power distribution box installation efficiency

A distribution box and efficiency technology, applied in the direction of switchgear, electrical components, etc., can solve the problems of increasing the time required for installing the distribution box, increasing the labor intensity of workers, and reducing work efficiency, so as to reduce the labor intensity of workers and improve Efficiency, the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

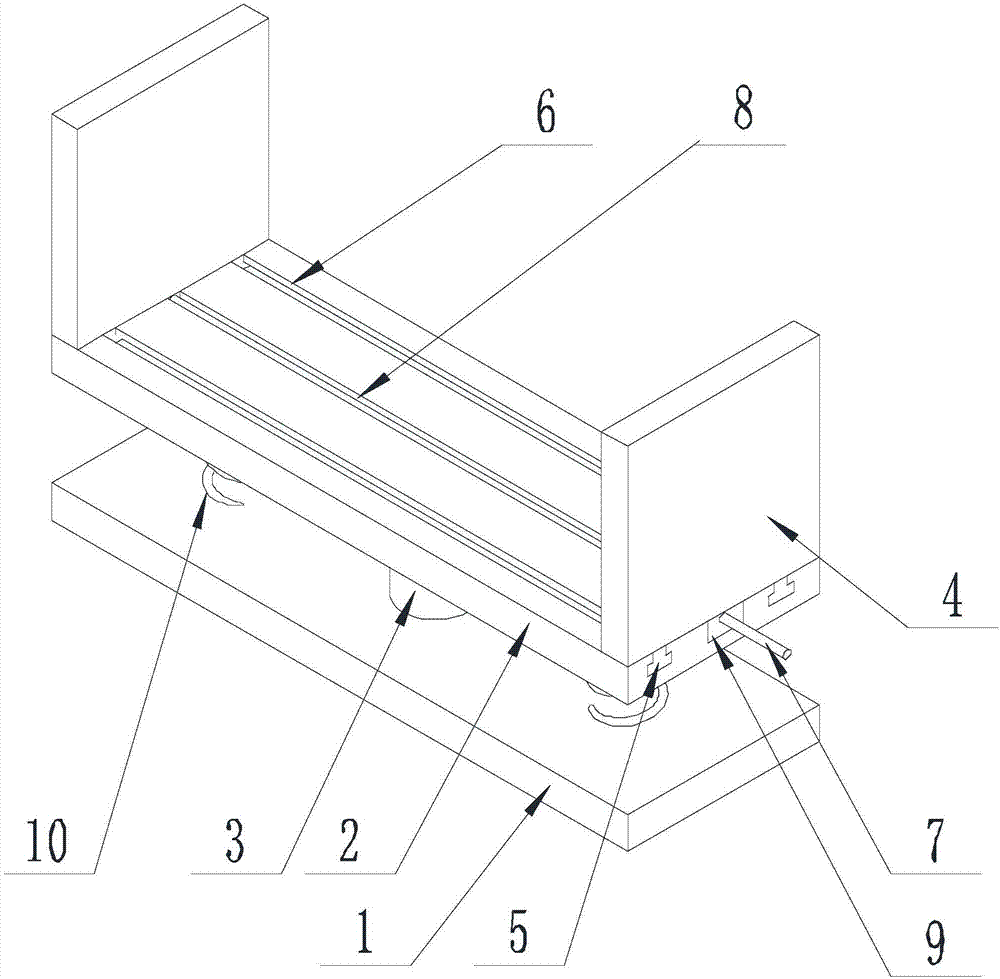

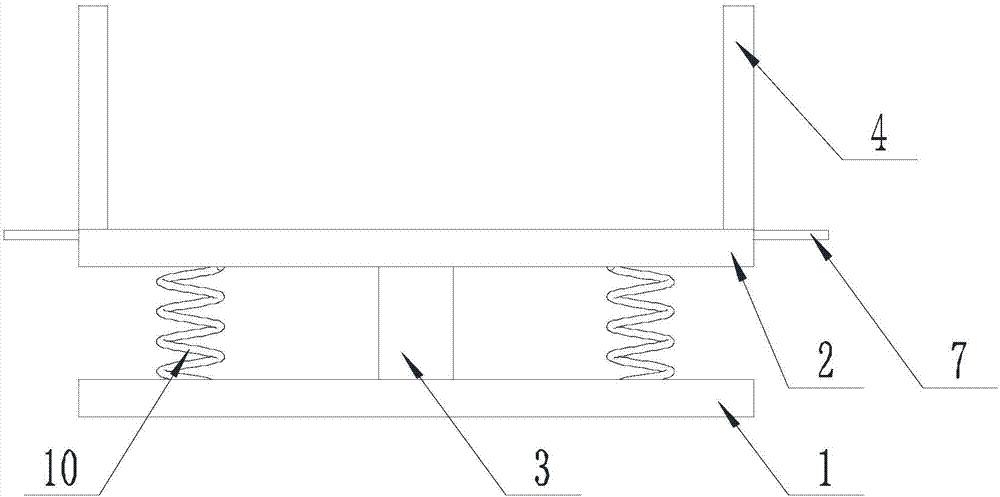

[0042] like Figure 1-Figure 2 As shown, the method for improving the efficiency of installing a distribution box of the present invention includes the following steps:

[0043] Step A Installation: Install the lifting plate 2 on the top of the fixing plate 1 through the telescopic device 3, and then set one plywood 4 on the end of the lifting plate 2 away from the surface of the fixing plate 1, and the other plywood 4 is located on the lifting plate 2. The other end of the board surface, and the splint 4 is connected with the driving device;

[0044] Step B: Place one side of the lifting board 2 in contact with the wall, and make the surface of the fixed board 1 away from the lifting board 2 contact the ground, the plywood 4 is perpendicular to the wall, and then place the distribution box to be installed on the lifting board. on board 2 and between plywood 4;

[0045] Step C: Clamping: start the controller to start the driving device, so that the clamping plates 4 are clos...

Embodiment 2

[0049] The present invention is further described on the basis of Embodiment 1.

[0050] like Figure 1-Figure 2 As shown, the method of the present invention to improve the efficiency of installing a distribution box, the driving device includes a screw 7 and a motor, and a driving block 9 is provided on the end of the splint 4 close to the lifting plate 2, and the lifting plate 2 is far from the fixing plate 1. A screw groove 8 is provided on the surface of the plate, the axis of the screw groove 8 is parallel to the moving track of the splint 4, the screw 7 is located in the screw groove 8, and the axis of the screw 7 is parallel to the moving track of the splint 4;

[0051] One end of the screw 7 is threadedly connected with the driving block 9 of one clamping plate 4, and the other end of the screw 7 is threadedly connected with the driving block 9 of the other clamping plate 4, and the rotation directions of the spiral lines at both ends of the screw 7 are opposite, and ...

Embodiment 3

[0053] The present invention is further described on the basis of Embodiment 1.

[0054] like Figure 1-Figure 2 As shown in the figure, the method of the present invention to improve the efficiency of installing the distribution box, is provided with a guide block 5 on one end of the splint 4 close to the lifting plate 2, and a guide groove 6 is provided on the plate surface of the lifting plate 2 away from the fixed plate 1, The extension axis of the guide groove 6 is parallel to the moving track of the clamping plate 4 , and the guide block 5 is located in the guide groove 6 and moves along the extension axis of the guide groove 6 .

[0055] Further, the size of the opening of the guide groove 6 is smaller than the size of the bottom of the groove, and the cross-sectional size of the guide block 5 is consistent with the cross-sectional size of the guide groove 6 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap